Description

1. Product Description

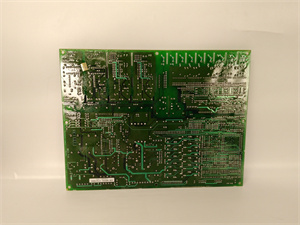

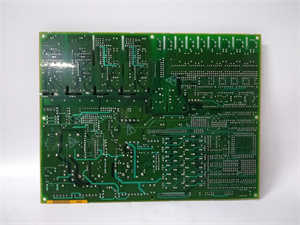

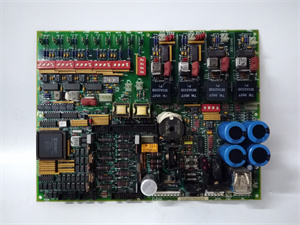

The DS200DCFBG1BJB is a high-reliability power supply board manufactured by General Electric (GE) for its Mark V Speedtronic turbine control systems. Designed for industrial automation and power generation applications, the DS200DCFBG1BJB provides redundant power supply, voltage regulation, and diagnostic capabilities to ensure stable operation of critical systems. It supports dual redundant input power (24V DC ±25%) with EMC filtering and delivers output voltages (3.3V DC, 5A; 5.0V DC, 5A) for control-level power in drives and enclosure fans. The board integrates advanced features like overcurrent protection, automatic input selection, and EEPROM-based diagnostic data storage, making it ideal for harsh industrial environments.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 24V DC ±25% (redundant dual input) |

| Output Voltage | 3.3V DC (±3%, 5A); 5.0V DC (±3%, 5A) |

| Input Power Range | 90–260 VAC (via control power transformer) |

| Frequency | 47–63 Hz |

| Output Power | Max. 26.5 W |

| Current Limit | 6 A (auto-recovery) |

| Diagnostic Storage | 512-byte EEPROM (10⁷ write cycles) |

| LED Indicators | Power status, fuse faults (115V AC, ±24V DC), and operational mode |

| Compatibility | GE Mark V, EX2000, DC2000, AC2000, and IGBT drive systems |

DS200DCFBG1BJB

3. Advantages and Features

- Redundant Power Architecture: Dual input power ensures continuous operation during transient faults (≤20ms impact).

- Robust Protection: Overcurrent limiting, short-circuit resistance, and voltage monitoring prevent system damage.

- Diagnostic Capabilities: Real-time voltage/current feedback, temperature monitoring, and EEPROM-based fault logging for predictive maintenance.

- Easy Integration: Configurable jumpers and DIP switches (7 switches, 12 jumpers) support custom settings for motor parameters (e.g., inrush current, cooling rates).

- EMC Compliance: Filtered interfaces and noise suppression for reliable performance in electromagnetic environments.

4. Application Areas and Use Cases

Industries: Power generation (gas/steam turbines), oil & gas, industrial automation.

Applications: Control systems for turbines, drives, and enclosure cooling.

Case Study: A coal-fired power plant in Europe used the DS200DCFBG1BJB to stabilize power supply in its Mark V system, reducing downtime by 30% through redundant power management and fault diagnostics.

Applications: Control systems for turbines, drives, and enclosure cooling.

Case Study: A coal-fired power plant in Europe used the DS200DCFBG1BJB to stabilize power supply in its Mark V system, reducing downtime by 30% through redundant power management and fault diagnostics.

5. Competitive Comparison

Compared to generic power supply boards, the DS200DCFBG1BJB offers:

- Native Compatibility: Seamless integration with GE Mark V systems (backward-compatible with first two revisions).

- Enhanced Safety: Factory-tested protection circuits (e.g., fuse monitoring with LED indicators) exceed industry standards.

- Longevity: Rugged design (coated PCB, heat sinks) for 10+ years of service in high-temperature environments.

DS200DCFBG1BJB

6. Selection Recommendations

- Compatibility: Verify revision compatibility (first two revisions support legacy systems).

- Environment: Ensure operating temperature (0–50°C) and humidity (5–95% non-condensing) match requirements.

- Budget: Balance upfront cost with long-term savings from reduced downtime and maintenance.

7. Precautions

- Installation: Follow GE’s manual (GEI-100028C) for proper wiring and grounding.

- Maintenance: Replace backup batteries every 5 years (monitored via LED).

- Safety: Disconnect power before servicing; use ESD protection during handling.