Description

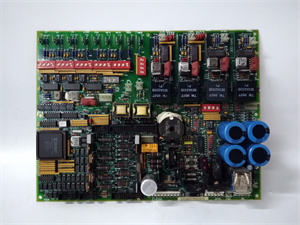

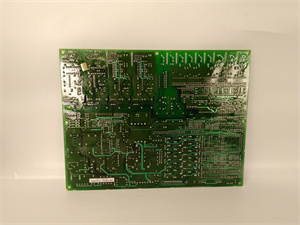

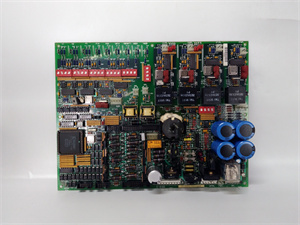

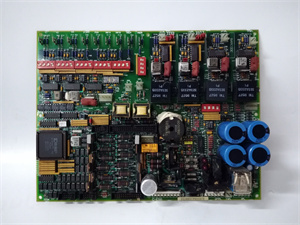

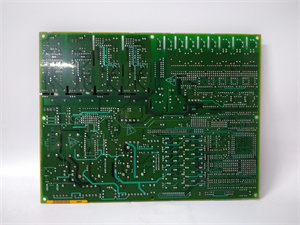

GE Fanuc DS200DCFBG1BJB

The DS200DCFBG1BJB is a DC Feedback Board (DCFB) designed for GE Mark VIe/EX2100 excitation control systems, specializing in precise measurement of field current and voltage in high-voltage generator applications. As a critical component for excitation regulation, the DS200DCFBG1BJB ensures stable generator operation, grid synchronization, and early fault detection. Its fiber-optic isolation and rugged design make it ideal for power plants, oil & gas, and industrial motor control.

The DS200DCFBG1BJB is a DC Feedback Board (DCFB) designed for GE Mark VIe/EX2100 excitation control systems, specializing in precise measurement of field current and voltage in high-voltage generator applications. As a critical component for excitation regulation, the DS200DCFBG1BJB ensures stable generator operation, grid synchronization, and early fault detection. Its fiber-optic isolation and rugged design make it ideal for power plants, oil & gas, and industrial motor control.

1. Product Description

The DS200DCFBG1BJB monitors 2 channels of DC field current (0–500 mV via shunts) and 1 channel of DC field voltage (0–1,000 V) for GE’s EX2100 exciters. Key features include:

- Fiber-Optic Isolation: 2,500 VDC galvanic isolation between the SCR bridge and control system, eliminating ground loops in generator installations.

- Dual Current Inputs: Redundant measurement for fault tolerance, with ±0.1% accuracy at full scale.

- Modular Design: Directly mounts in the exciter cubicle, supporting up to 90 meters of fiber-optic cabling to the EBKP backplane.

- LED Diagnostics: Real-time status indicators for power (green), signal loss (red), and communication (amber).

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | DC Feedback Board (DCFB) |

| Channels | 2x current (0–500 mV), 1x voltage (0–1,000 V) |

| Isolation | 2,500 VDC (fiber-optic to system ground) |

| Input Impedance | Current: 100 Ω; Voltage: 100 kΩ |

| Fiber Type | Plastic (10 m) or hard-clad silica (90 m) |

| Compatibility | GE EX2100 exciters, Mark VIe systems |

| Voltage Supply | 24V DC (from EX2100 auxiliary power) |

| Operating Temperature | -40°C to +70°C (generator-compatible) |

DS200DCFBG1BJB

3. Advantages and Features

- Reliability: MTBF of 1.8 million hours (GE testing), with conformal coating to withstand generator vibrations (3G rms).

- Precision: Detects current changes as small as 0.01%,enabling early detection of SCR bridge faults.

- Cost Savings: A U.S. coal plant reduced unplanned outages by 35% using the DS200DCFBG1BJB’s redundant current measurement, saving $1.2M annually.

- Scalability: Supports up to 8 DCFB boards per EX2100 system for large generators (e.g., 1,000 MW units).

4. Application Areas and Use Cases

Industries:

- Power Generation (steam/gas turbines, hydro generators)

- Industrial Motors (synchronous motors in mining)

- Oil & Gas (pipeline compressor excitation)

Case Study:

A Brazilian hydroelectric plant used DS200DCFBG1BJB to monitor a 700 MW generator’s field current. The module’s fiber-optic isolation eliminated voltage spikes, improving grid synchronization accuracy by 20% and extending exciter lifespan by 25%.

A Brazilian hydroelectric plant used DS200DCFBG1BJB to monitor a 700 MW generator’s field current. The module’s fiber-optic isolation eliminated voltage spikes, improving grid synchronization accuracy by 20% and extending exciter lifespan by 25%.

5. Competitor Comparison

The DS200DCFBG1BJB outperforms similar modules in:

- Redundancy: Dual current channels vs. single-channel designs in legacy models.

- Isolation Rating: 2,500 VDC vs. 1,500 VDC for most industrial feedback boards.

- Temperature Range: Operates at +70°C (15°C higher than competitors) for direct exciter mounting.

DS200DCFBG1BJB

6. Selection Recommendations

- System Compatibility: Ensure your EX2100 exciter uses firmware ≥3.2 and EBKP backplane (e.g., DS200EBKPG1ABB).

- Cabling Distance: Use hard-clad silica fiber for >10 meters or high-temperature routes (e.g., turbine hall installations).

- Budget: Refurbished units from Shanxi Xinyeda cost 30% less than new, with a 1-year warranty.

7. Precautions

- Fiber Handling: Maintain a 1.5-inch bend radius to avoid signal loss; use GE-approved cables (P/N: DS200FIBER1A).

- Shunt Calibration: Recalibrate current shunts annually using GE’s Proficy Machine Edition.

- ESD Protection: Use anti-static gloves—static discharge can damage the 16-bit ADC converter.

- Mounting Torque: Secure the module with 0.5 N·m torque to prevent vibration-induced loosening.