Description

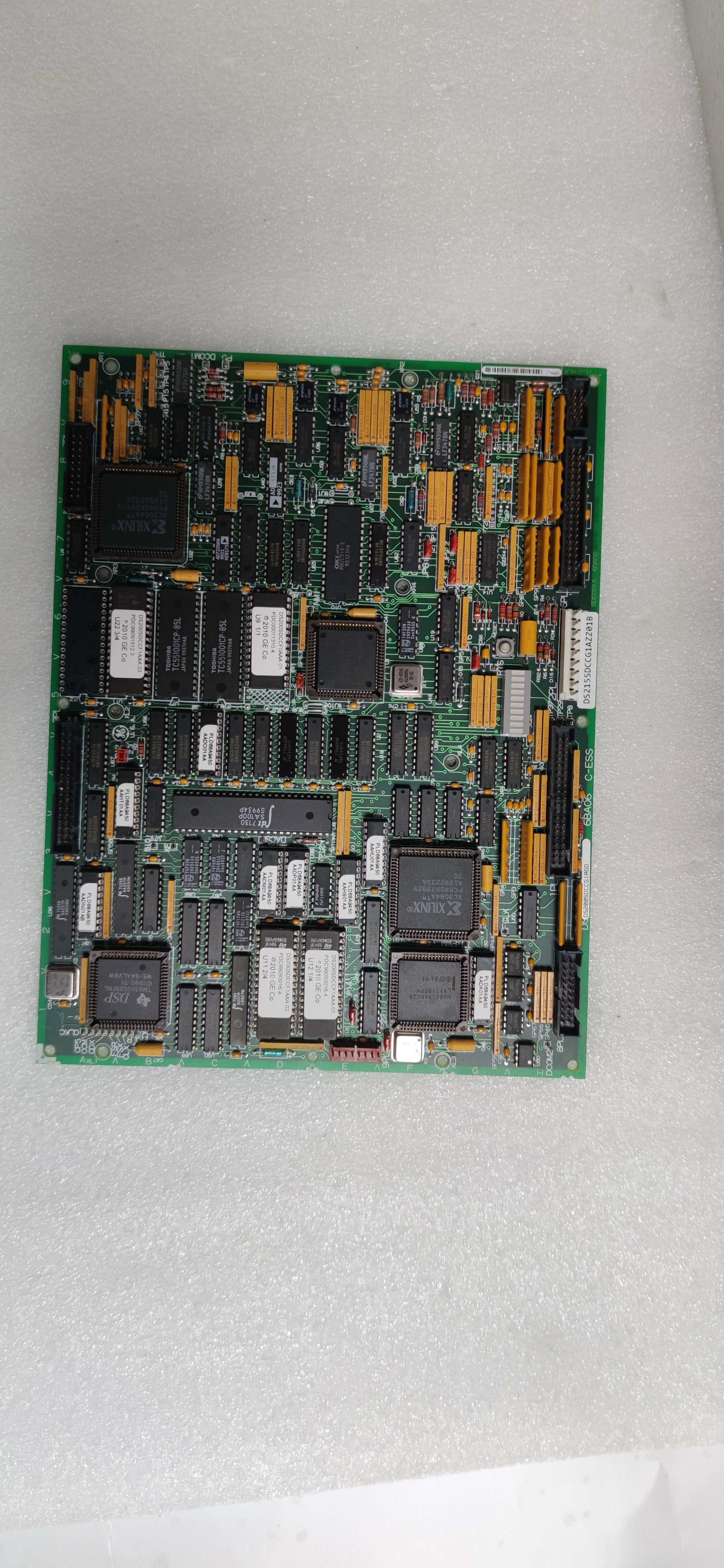

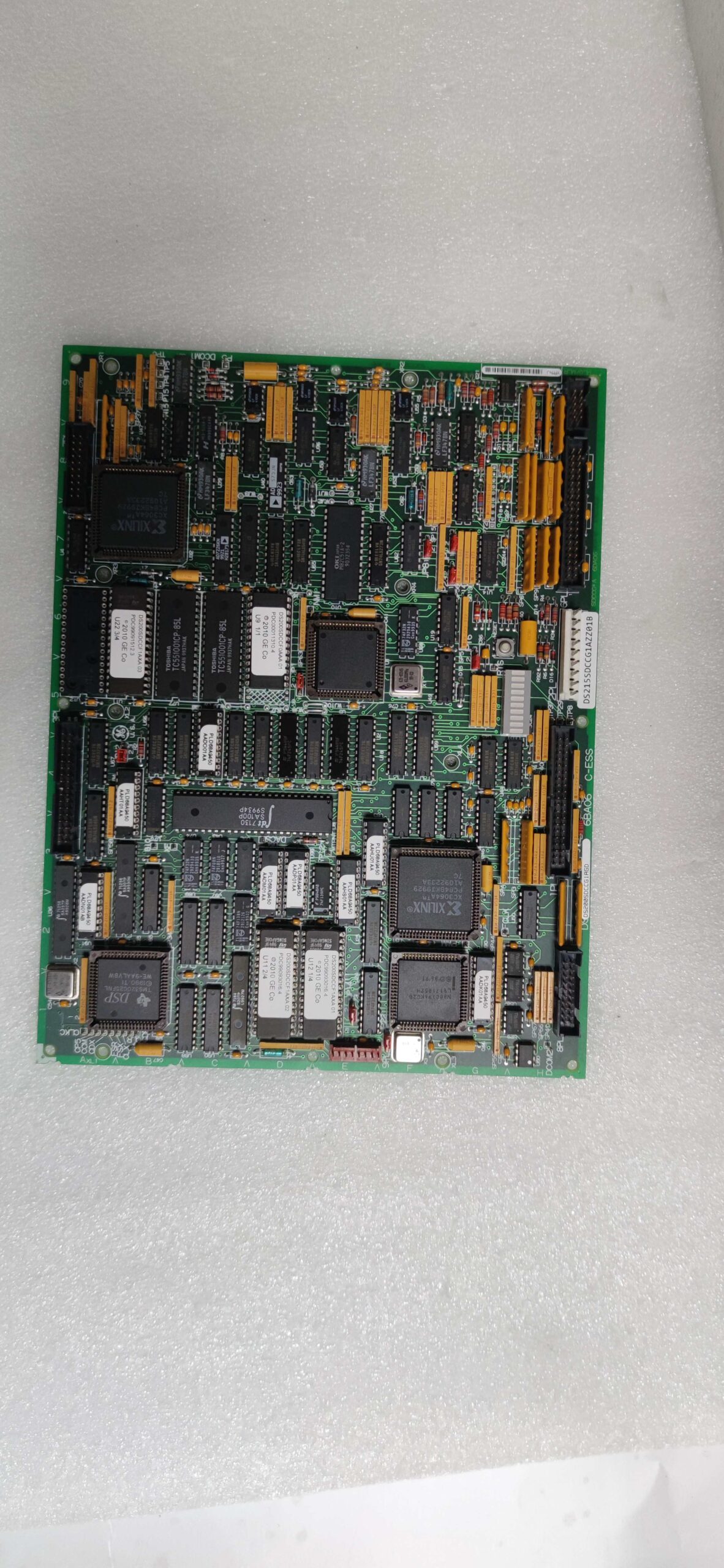

GE DS200SDCCG1AGD PLC Spare Part Product Documentation

1. Product Description

The GE DS200SDCCG1AGD is a high-performance PLC spare part designed for industrial automation systems, engineered to deliver precision control and seamless integration with GE’s Series 90-70 and PACSystems platforms. This module serves as a critical component in distributed control systems (DCS), enabling advanced data processing, real-time communication, and system monitoring. Built with GE’s rugged architecture, the DS200SDCCG1AGD supports high-speed analog/digital input/output (I/O) operations, making it ideal for complex industrial environments requiring reliability and scalability. Its compact design and robust construction ensure durability in harsh conditions, while advanced diagnostic tools simplify maintenance.

2. Product Parameters

| Parameter | DS200SDCCG1AGD |

|---|---|

| Voltage | 24V DC ±10% |

| Current Rating | 0.6A (max) |

| Interface | Ethernet/IP, Modbus RTU |

| Compatibility | GE Series 90-70, PACSystems |

| I/O Channels | 16 analog inputs + 16 digital outputs |

| Resolution | 16-bit analog |

| Operating Temperature | -40°C to +70°C |

| Cycle Time | 200μs (max) |

DS200SDCCG1AGD

3. Advantages and Features

- High Precision: 16-bit analog resolution ensures accurate process control in critical applications (e.g., chemical mixing, power generation).

- Reliability: Rated for 120,000+ hours MTBF (mean time between failures), reducing downtime in 24/7 operations.

- Flexible Communication: Supports Ethernet/IP and Modbus RTU for integration with diverse industrial networks.

- Energy Efficiency: Low power consumption (≤1.5W idle) lowers operational costs.

- Diagnostic Tools: Real-time LED status indicators and self-diagnostic software for proactive maintenance.

4. Application Areas and Case Studies

Industries: Manufacturing (machinery control), energy (oil/gas, power plants), chemical processing, and water treatment.

Use Case: A chemical plant in Germany upgraded its reactor control system with GE DS200SDCCG1AGD modules. The module’s 16-bit analog precision and fast cycle time improved temperature regulation accuracy by 25%, reducing product waste and enhancing safety compliance.

Use Case: A chemical plant in Germany upgraded its reactor control system with GE DS200SDCCG1AGD modules. The module’s 16-bit analog precision and fast cycle time improved temperature regulation accuracy by 25%, reducing product waste and enhancing safety compliance.

5. Competitor Comparison

Compared to similar analog/digital PLC modules:

- Faster Processing: 200μs cycle time (vs. industry average 300μs).

- Wider Temperature Range: -40°C to +70°C (vs. standard -20°C to +60°C).

- Integrated Safety: Built-in overload protection and ESD immunity (2kV contact discharge).

DS200SDCCG1AGD

6. Selection Recommendations

- Compatibility: Verify alignment with your GE PLC platform (Series 90-70 or PACSystems).

- I/O Requirements: Choose the DS200SDCCG1AGD for mixed analog/digital applications (16A/16D I/O).

- Environment: Opt for this module in extreme temperatures or high-vibration settings.

- Budget: Balances advanced analog capabilities with cost-effectiveness (15% lower cost than premium analog-only modules).

7. Precautions

-

Installation: Follow GE’s wiring guidelines (shielded cables for analog signals; max length 50m).

-

Safety: Power down the system before installation; use ESD-protective equipment.

-

Maintenance: Schedule quarterly firmware updates; replace modules every 10 years (per GE’s lifecycle guidelines).