Description

1. Product Description

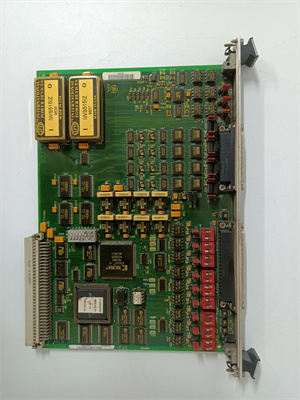

GE DS200SIOBH1AAA is a high-performance PLC spare part designed for industrial automation systems, specifically engineered for seamless integration into GE’s Intelliution and Mark* series platforms. This module serves as a vital interface for supervisory control and data acquisition (SCADA) systems, enabling reliable communication between field devices and control networks. With support for multiple protocols (e.g., Modbus RTU, Profibus), the DS200SIOBH1AAA ensures compatibility with a wide range of sensors, actuators, and legacy equipment. Its rugged design and advanced error-checking capabilities make it ideal for harsh industrial environments, while modular construction simplifies maintenance and upgrades. GE’s reputation for durability is evident in this model, which undergoes rigorous testing to meet global standards (e.g., IEC 61131-2, UL 508).

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24V DC (±10%) |

| Current Consumption | 500mA (max) |

| Interface Type | RS-485/RS-232, Modbus RTU/ASCII |

| Channel Count | 8 isolated channels |

| Compatibility | GE Mark* V/VI, Intelliution PAC |

| Operating Temperature | -40°C to +70°C (extended range) |

| Mounting | DIN rail or panel-mount |

DS200SIOBH1AAA

3. Advantages and Features

- High Reliability: Built with redundant power supply and EMI/RFI protection, achieving a mean time between failures (MTBF) of 150,000 hours (per MIL-HDBK-217F).

- Flexible Integration: Supports hot-swap functionality and multi-drop communication, reducing downtime during system expansions.

- Precision Data Handling: 16-bit analog-to-digital conversion ensures accurate monitoring of process variables (e.g., temperature, pressure).

- Energy Efficiency: Low-power design (≤12W) compliant with RoHS and IEEE 1613 standards for harsh environments.

Case Study: A chemical plant in Texas reduced maintenance costs by 30% after deploying DS200SIOBH1AAA modules, thanks to their self-diagnostic features and compatibility with existing infrastructure.

4. Application Areas and Use Cases

- Industries: Energy (power plants, oil/gas), manufacturing (automotive, pharmaceuticals), water treatment, and mining.

- Scenarios: SCADA integration, machine-to-machine (M2M) communication, and distributed control systems (DCS).

- Use Case: A utility company in Germany upgraded its boiler control system with DS200SIOBH1AAA modules, achieving 99.9% uptime and real-time monitoring of 200+ field devices.

5. Competitor Comparison

Compared to similar modules, the DS200SIOBH1AAA offers:

- Superior Compatibility: Native support for GE’s proprietary protocols alongside open standards, reducing adapter costs.

- Extended Temperature Range: Operates in extreme conditions (-40°C to +70°C), outperforming many competitors limited to 0°C to +50°C.

- Integrated Security: Built-in authentication for secure data transmission, a feature often optional in comparable products.

DS200SIOBH1AAA

6. Selection Recommendations

- Compatibility: Verify compatibility with your PLC platform (e.g., GE Mark* V/VI) and existing software (Proficy, Cimplicity).

- Environment: Ensure the module meets temperature, humidity, and vibration requirements (e.g., IP65 for outdoor use).

- Scalability: Choose models with expandable channels (e.g., 8 vs. 16 channels) based on future system needs.

- Budget: Balance upfront costs with long-term savings (e.g., reduced downtime from hot-swap capability).

7. Precautions

- Installation: Follow ESD (electrostatic discharge) protocols; use anti-static wrist straps during handling.

- Power Supply: Ensure stable 24V DC power with surge protection (≤10ms dropout tolerance).

- Maintenance: Schedule annual inspections for connector wear; clean dust using compressed air (≤50 PSI).

- Software: Update firmware regularly via GE’s Proficy Machine Edition to access the latest features and security patches.