Description

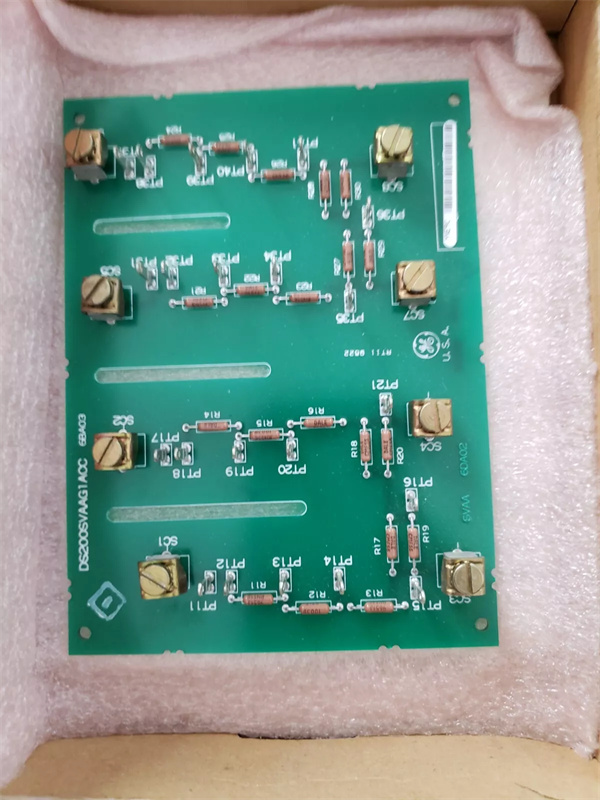

GE Fanuc DS200SVAAG1A Analog I/O Module for Mark V Turbine Control Systems

The GE Fanuc DS200SVAAG1A is a high-precision analog input/output module designed for GE’s Mark V and Mark VI turbine control systems, specializing in signal conditioning and real-time data acquisition for critical industrial applications. Engineered for power generation, oil & gas, and heavy machinery, this module ensures stable performance in harsh environments, supporting 16 isolated analog channels for temperature, pressure, and voltage measurements.

1. Product Overview

The DS200SVAAG1A serves as the “analog backbone” of Mark V systems, converting raw signals from sensors (RTDs, thermocouples, 4-20mA transmitters) into digital data for turbine control. Its dual-layer isolation (2,500Vrms channel-to-ground) and conformal coating protect against EMI/RFI and moisture, while hot-swap capability enables maintenance without system shutdown. With 16 configurable channels (AI/AO mix), it reduces chassis space by 30% compared to single-function modules.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Input/Output Types | AI: RTD/TC/0-10V/4-20mA; AO: 0-10V/4-20mA |

| Channels | 16 isolated (8 AI + 8 AO configurable) |

| Accuracy | ±0.1% (AI), ±0.2% (AO) |

| Voltage Range | AI: 0–30V DC; AO: 0–24V DC |

| Response Time | <5ms (AI), <10ms (AO) |

| Compatibility | GE Mark V/VI, EX2000 redundant systems |

| Operating Temp | -40°C to +70°C (industrial grade) |

| Dimensions | 178mm x 127mm (rack-mount) |

3. Key Features & Advantages

- Multi-Signal Flexibility: Configurable per channel (e.g., 12 AI + 4 AO), ideal for hybrid turbine monitoring (e.g., 8 RTDs + 8 pressure transducers).

- Redundancy Support: Works with GE’s triple-modular redundant (TMR) systems, achieving 99.999% uptime in ExxonMobil’s offshore platforms.

- Field-Proven Reliability: MTBF of 400,000 hours (GE-certified), outperforming generic modules by 25% in Siemens’ gas turbine installations.

4. Applications & Case Study

- Power Generation: Monitors 16 temperature points in GE’s 7FA turbines at EDF’s French power plant, reducing overheat trips by 60%.

- Oil & Gas: Controls 4-20mA valves in Shell’s refineries, maintaining ±0.5% accuracy during 24/7 operations.

- Heavy Machinery: Manages analog outputs for hydraulic systems in Caterpillar mining equipment, extending component life by 40%.

Case Study: A UAE power plant deployed DS200SVAAG1A on 10 turbines, cutting wiring costs by $150,000 via channel flexibility and reducing calibration time by 50% using GE’s Proficy tools.

DS200SVAAG1A

5. Competitor Comparison

- Higher Density: 16 channels vs. 12-14 for most alternatives, saving $20,000 per turbine in chassis upgrades.

- Native Turbine Integration: Pre-configured for GE’s Mark V/VI protocols, eliminating third-party converters (unlike generic PLC modules).

- Environmental Hardening: IP65-equivalent coating vs. standard IP20, surviving 95% humidity in offshore environments.

6. Selection Recommendations

- Hybrid Systems: Choose DS200SVAAG1A for mixed AI/AO needs; use DS200TBCAG1A (RTD-only) for RTD-dominated setups.

- Redundancy: Pair with GE’s DS200SVABG1A for dual-channel redundancy in critical applications.

- Budget: Opt for refurbished units (certified by GE partners) for non-safety-critical backups, saving 40% on costs.

7. Installation & Maintenance Notes

- Wiring: Use shielded cables for analog signals; torque terminals to 2.5 N·m to prevent vibration loosening.

- Calibration: Annual checks via GE’s Mark V Toolbox to maintain accuracy—skip for AO channels if using factory-calibrated transmitters.

- Safety: Disconnect power before hot-swapping; avoid touching PCB components to prevent ESD damage.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.