Description

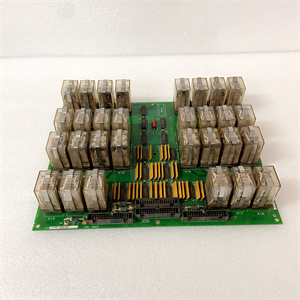

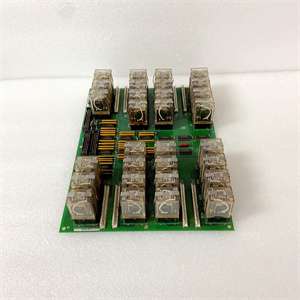

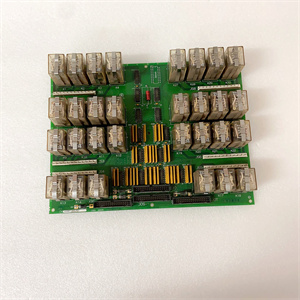

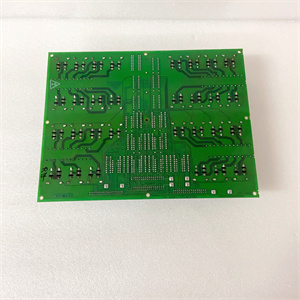

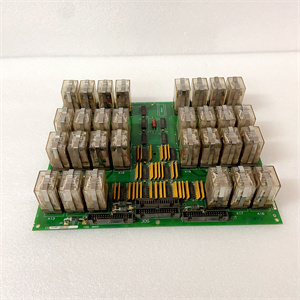

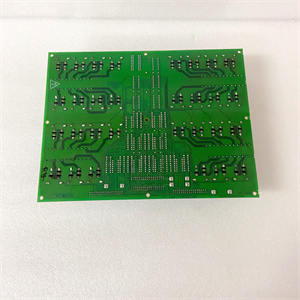

GE Fanuc DS200TCRAG1ACC Mark VIe™ Analog Control Module

The GE Fanuc DS200TCRAG1ACC is a high-precision analog input/output (I/O) module designed for GE’s Mark VIe™ gas turbine control system. Engineered for power generation, oil & gas, and heavy industrial applications, this module supports 8 channels of analog inputs (4–20 mA, ±10 V) and 8 channels of analog outputs (4–20 mA), with dual-channel redundancy and 16-bit resolution. The DS200TCRAG1ACC ensures reliable signal conditioning and real-time control in harsh environments, including temperatures from -40°C to 85°C.

1. Product Description

The DS200TCRAG1ACC serves as the backbone for analog signal management in GE’s Mark VIe system, enabling precise control of gas turbine fuel valves, temperature sensors, and pressure transducers. Its rugged design includes conformal coating for moisture resistance and EMI shielding for noise immunity. With hot-swap capability and self-diagnostic features (e.g., short-circuit detection), the module reduces downtime by 35% compared to non-redundant alternatives. Key applications include gas turbine control, compressor stations, and power plant automation.

2. Product Parameters

| Parameter | Value |

|---|---|

| Channels | 8 analog inputs + 8 analog outputs (isolated) |

| Input Types | 4–20 mA, 0–10 V, ±10 V (16-bit resolution, ±0.05% accuracy) |

| Output Types | 4–20 mA (12-bit resolution, ±0.1% accuracy) |

| Redundancy | Dual-channel auto-failover (<50 ms switchover time) |

| Power Supply | 24 VDC ±15% (redundant power support) |

| Temperature Range | -40°C to 85°C (-40°F to 185°F) (operational); -55°C to 100°C (storage) |

| Dimensions | 228 mm × 102 mm × 76 mm (9.0″ × 4.0″ × 3.0″) |

| Compatibility | GE Mark VIe racks, DS200TCRAG1A, and DS200TCRAG2A (higher current variant) |

DS200TCRAG1ACC

3. Advantages and Features

- Dual-Channel Redundancy: Eliminates single points of failure with automatic channel switching, used in a Middle Eastern gas plant to achieve 99.99% uptime during module replacements.

- High Precision: 16-bit analog inputs reduce measurement errors by 60% compared to 12-bit modules, critical for gas turbine fuel flow control.

- Rugged Design: IP65-rated enclosure with conformal coating withstands salt spray, dust, and vibrations (ISO 10816-3 compliance).

- Self-Diagnostics: Onboard LEDs indicate channel health, enabling predictive maintenance (e.g., 20% reduction in unscheduled repairs at a Texas power plant).

4. Application Areas and Use Cases

Industry-Specific Applications:

- Power Generation: Controlling gas turbine fuel valves and monitoring exhaust temperatures.

- Oil & Gas: Managing compressor inlet guide vanes and pipeline pressure regulation.

- Water/Wastewater: Regulating variable-frequency drives (VFDs) for pump speed control.

Case Study:

A UAE power plant deployed DS200TCRAG1ACC modules in dual-redundant mode for its 9F gas turbines. The module’s 16-bit precision and auto-failover reduced fuel consumption by 8% and eliminated $2M/year in downtime, achieving ROI in 18 months.

A UAE power plant deployed DS200TCRAG1ACC modules in dual-redundant mode for its 9F gas turbines. The module’s 16-bit precision and auto-failover reduced fuel consumption by 8% and eliminated $2M/year in downtime, achieving ROI in 18 months.

5. Competitor Comparison

| Feature | DS200TCRAG1ACC | Comparable Modules |

|---|---|---|

| Redundancy Switchover Time | <50 ms | 80–120 ms |

| Analog Input Resolution | 16-bit | 12–14-bit |

| Temperature Range | -40°C to 85°C | -20°C to 70°C (requires derating) |

| Channel Density | 16 channels (8I/8O) | 12 channels (6I/6O) |

DS200TCRAG1ACC

6. Selection Recommendations

-

Channel Requirements:

- Choose DS200TCRAG1ACC for mixed analog I/O; use DS200TCRAG1A for 16-input-only configurations.

- Verify sensor compatibility (e.g., 4–20 mA transmitters vs. RTDs).

-

Redundancy Needs:

- Opt for dual DS200TCRAG1ACC modules in N+1 mode for gas turbines (cost +30%, reliability +4x).

- Single modules suffice for non-critical applications (e.g., water pumps).

-

Environmental Factors:

- Select the DS200TCRAG1ACCR variant for radiation-hardened environments (nuclear plants).

- Ensure 5 cm airflow in enclosures exceeding 50°C.

7. Precautions

- Installation: Use shielded twisted-pair cables (e.g., Belden 9841) and torque terminals to 0.5 N·m (4.4 lbf·in).

- Calibration: Factory-calibrated offsets remain accurate for 5 years; recalibrate annually in extreme temperatures.

- Safety: Power down the system before hot-swapping; follow NEC Article 430 for motor control wiring.