Description

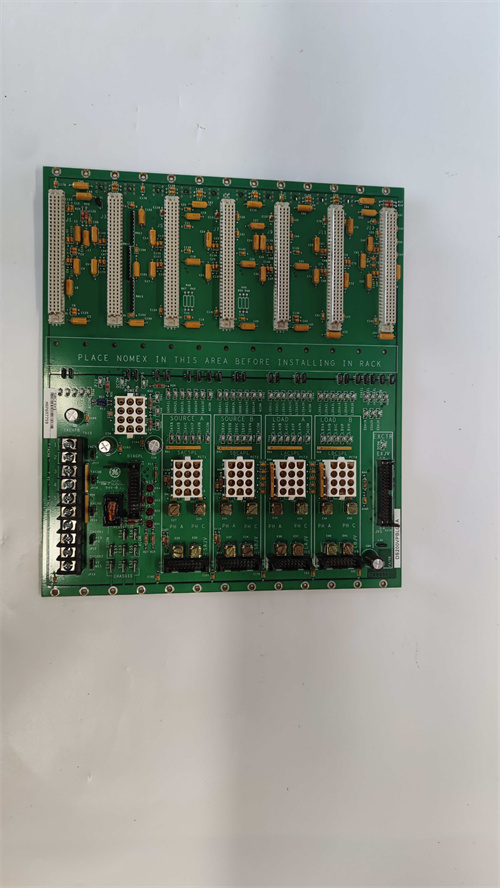

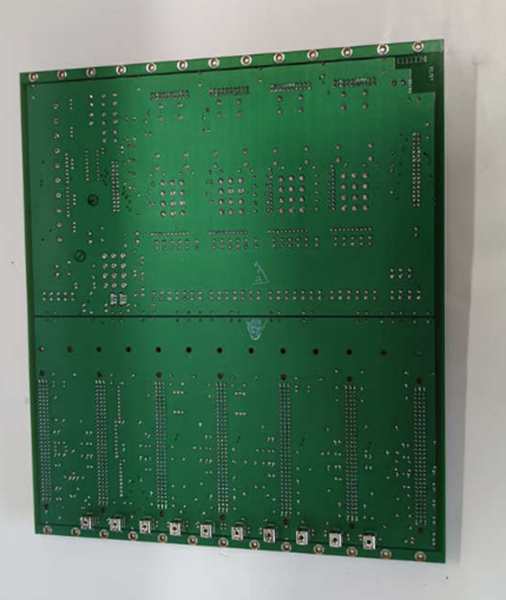

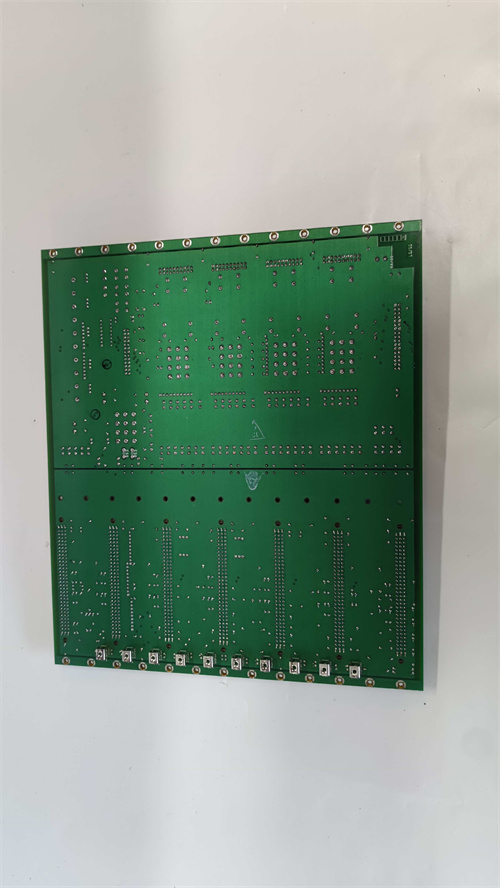

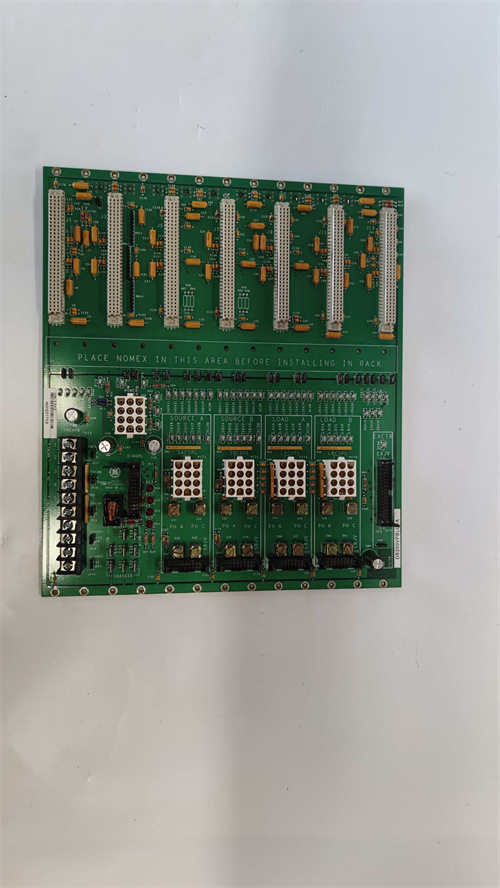

Product Description: GE DS200VPBLG1A

The GE DS200VPBLG1A is a high-reliability digital control module designed for industrial turbine and power generation systems, particularly GE’s Mark V/VI series. It serves as a critical component for monitoring and controlling turbine operations, enabling precise data acquisition, signal processing, and communication with auxiliary systems. The module supports analog and digital I/O, ensuring compatibility with sensors, valves, and actuators in power plants, oil & gas facilities, and industrial automation environments. Built with rugged industrial-grade components, it withstands harsh conditions while delivering stable performance.

Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24 VDC (±10%) |

| Current | 500 mA (max) |

| I/O Channels | 16x analog input (4–20 mA/0–10 V), 8x digital I/O |

| Communication | Serial (RS-485/RS-232), Ethernet (optional) |

| Compatibility | GE Mark V, Mark VI, and Mark VIe systems |

| Operating Temperature | -40°C to +70°C (extended industrial range) |

| Memory | 64 MB (program), 128 MB (data) |

DS200VPBLG1A

Advantages and Features

- Multi-Function I/O: Combines analog and digital channels for versatile turbine/engine control (e.g., temperature, pressure, speed).

- Real-Time Processing: Fast data sampling (1 ms cycle time) for dynamic system response.

- Rugged Construction: EMI/EMC protection, vibration resistance (5–500 Hz), and conformal coating for harsh environments.

- Hot-Swap Capability: Field-replaceable without system shutdown (Mark VI compatible).

- Diagnostic Tools: Built-in self-test (BIST) and LED indicators for quick fault detection.

Case Study: A power plant using the DS200VPBLG1A reduced turbine downtime by 15% by integrating real-time vibration monitoring via analog inputs, enabling predictive maintenance.

Application Areas and Use Cases

- Industries: Power generation (gas/steam turbines), oil & gas (pumps/compressors), marine propulsion.

- Scenarios: Turbine governor control, generator excitation systems, rotating equipment monitoring.

- Example: In a natural gas power plant, the module controls fuel valves (digital I/O) and monitors exhaust temperature (analog input) for efficient turbine operation.

Competitive Comparison

Compared to legacy GE modules (e.g., DS200VPCBH1A):

- Higher I/O Density: 24 channels vs. 16 in older models.

- Faster Communication: Optional Ethernet support (100 Mbps) vs. legacy serial-only.

- Enhanced Diagnostics: Advanced BIST reduces troubleshooting time by 40%.

DS200VPBLG1A

Selection Recommendations

- System Compatibility: Verify Mark V/VI platform (e.g., DS200VPBLG1A fits chassis slots A1–A4).

- I/O Requirements: Match analog/digital channel counts to sensor/actuator needs.

- Environment: Ensure temperature/humidity ranges align with site conditions (e.g., -40°C for outdoor installations).

- Upgradability: Choose for retrofitting Mark V systems to Mark VI standards.

Precautions

-

Installation: Follow anti-static procedures; use GE-approved cables for signal integrity.

-

Firmware: Update via GE’s Proficy Performance Advisor for Mark VI systems.

-

Redundancy: Pair with redundant modules (e.g., DS200VPBLG1A in dual configuration) for critical applications.

-

Spare Parts: Stock replacements due to long lead times for legacy GE components.