Description

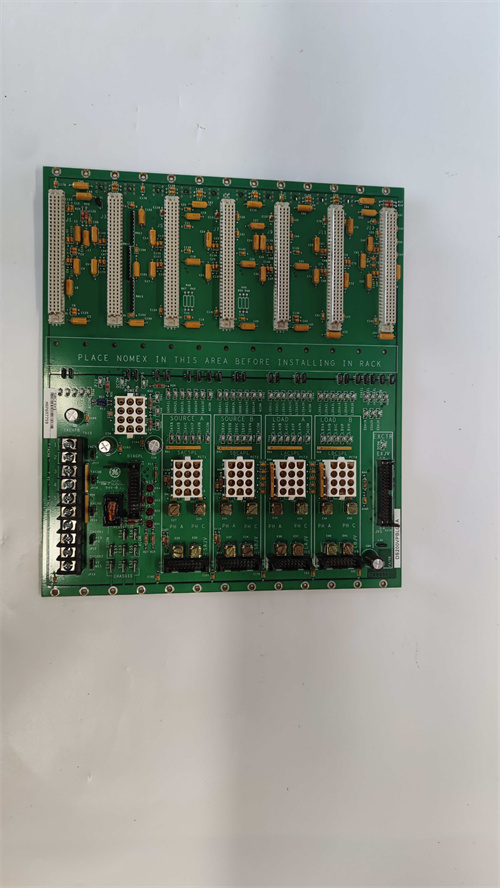

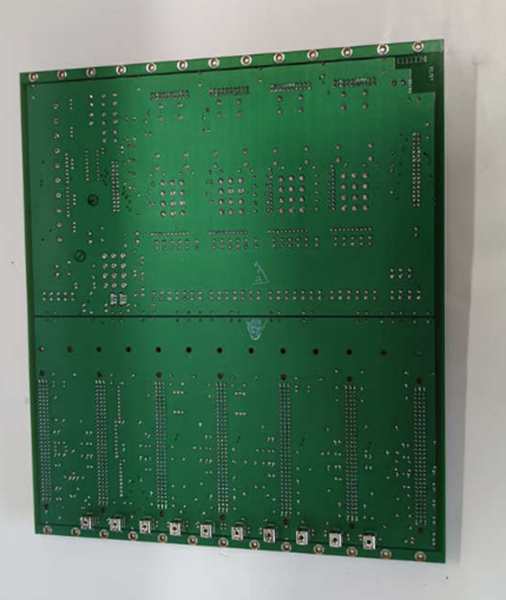

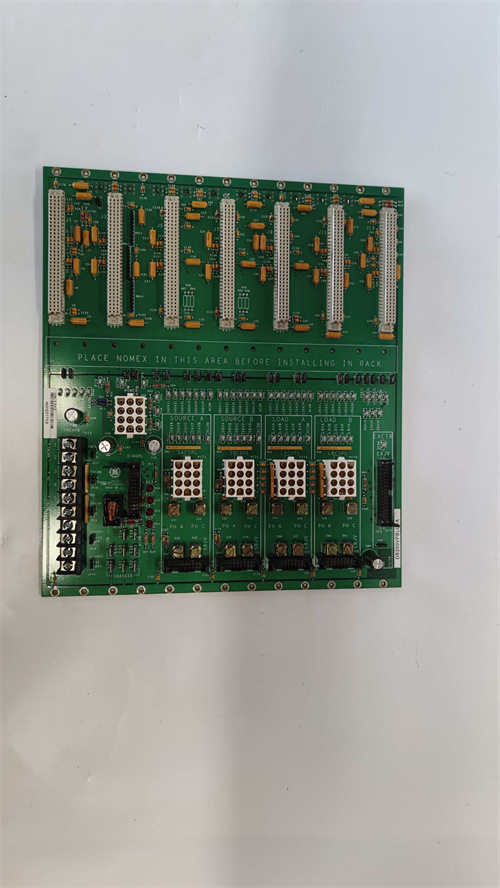

Product Description: GE DS200VPBLG1A

The GE DS200VPBLG1A is a high-reliability digital control module designed for industrial turbine and power generation systems, particularly GE’s Mark V/VI series. It serves as a critical component for monitoring and controlling turbine operations, enabling precise data acquisition, signal processing, and communication with auxiliary systems. The module supports analog and digital I/O, ensuring compatibility with sensors, valves, and actuators in power plants, oil & gas facilities, and industrial automation environments. Built with rugged industrial-grade components, it withstands harsh conditions while delivering stable performance.

Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24 VDC (±10%) |

| Current | 500 mA (max) |

| I/O Channels | 16x analog input (4–20 mA/0–10 V), 8x digital I/O |

| Communication | Serial (RS-485/RS-232), Ethernet (optional) |

| Compatibility | GE Mark V, Mark VI, and Mark VIe systems |

| Operating Temperature | -40°C to +70°C (extended industrial range) |

| Memory | 64 MB (program), 128 MB (data) |

DS200VPBLG1A

Advantages and Features

- Multi-Function I/O: Combines analog and digital channels for versatile turbine/engine control (e.g., temperature, pressure, speed).

- Real-Time Processing: Fast data sampling (1 ms cycle time) for dynamic system response.

- Rugged Construction: EMI/EMC protection, vibration resistance (5–500 Hz), and conformal coating for harsh environments.

- Hot-Swap Capability: Field-replaceable without system shutdown (Mark VI compatible).

- Diagnostic Tools: Built-in self-test (BIST) and LED indicators for quick fault detection.

Case Study: A power plant using the DS200VPBLG1A reduced turbine downtime by 15% by integrating real-time vibration monitoring via analog inputs, enabling predictive maintenance.

Application Areas and Use Cases

- Industries: Power generation (gas/steam turbines), oil & gas (pumps/compressors), marine propulsion.

- Scenarios: Turbine governor control, generator excitation systems, rotating equipment monitoring.

- Example: In a natural gas power plant, the module controls fuel valves (digital I/O) and monitors exhaust temperature (analog input) for efficient turbine operation.

Competitive Comparison

Compared to legacy GE modules (e.g., DS200VPCBH1A):

- Higher I/O Density: 24 channels vs. 16 in older models.

- Faster Communication: Optional Ethernet support (100 Mbps) vs. legacy serial-only.

- Enhanced Diagnostics: Advanced BIST reduces troubleshooting time by 40%.

DS200VPBLG1A

Selection Recommendations

- System Compatibility: Verify Mark V/VI platform (e.g., DS200VPBLG1A fits chassis slots A1–A4).

- I/O Requirements: Match analog/digital channel counts to sensor/actuator needs.

- Environment: Ensure temperature/humidity ranges align with site conditions (e.g., -40°C for outdoor installations).

- Upgradability: Choose for retrofitting Mark V systems to Mark VI standards.

Precautions

-

Installation: Follow anti-static procedures; use GE-approved cables for signal integrity.

-

Firmware: Update via GE’s Proficy Performance Advisor for Mark VI systems.

-

Redundancy: Pair with redundant modules (e.g., DS200VPBLG1A in dual configuration) for critical applications.

-

Spare Parts: Stock replacements due to long lead times for legacy GE components.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.