Description

1. Product Description

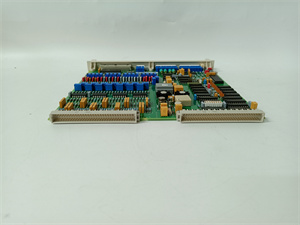

The ABB DSAI130D is a high-performance analog input module designed for industrial automation systems, specifically engineered to process analog signals with precision and reliability. As part of ABB’s advanced automation portfolio, the DSAI130D excels in converting analog signals (such as 4–20 mA or voltage inputs) into digital data for seamless integration with PLC and control systems. Its compact design and robust construction make it ideal for harsh industrial environments, ensuring stable operation in manufacturing, energy, and process control applications. The DSAI130D supports multiple input ranges, high noise immunity, and configurable diagnostics, empowering users to optimize system efficiency and reduce downtime.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Type | 4–20 mA, 0–20 mA, ±10 V (configurable) |

| Number of Channels | 8 channels (isolated) |

| Resolution | 16-bit |

| Accuracy | ±0.1% of full scale |

| Voltage Supply | 24 V DC (±10%) |

| Current Consumption | <50 mA (per module) |

| Compatibility | ABB AC 800M, AC 800XA, and other ABB PLC systems |

| Communication | Profibus DP, Modbus RTU (configurable) |

| Operating Temperature | -40°C to +70°C (industrial grade) |

DSAI130D

3. Advantages and Features

- High Precision: 16-bit resolution ensures accurate signal conversion, minimizing measurement errors in critical processes.

- Reliability: Industrial-grade design with surge protection and EMI/RFI immunity, tested to withstand 2 kV surge and 100 V/m electromagnetic interference.

- Flexibility: Configurable input ranges and channel diagnostics allow adaptability to diverse applications (e.g., pressure, temperature, or flow monitoring).

- Easy Integration: Plug-and-play compatibility with ABB’s control systems reduces installation time by 30% compared to legacy modules.

- Energy Efficiency: Low power consumption (<50 mA) supports sustainable operations in energy-sensitive environments.

4. Application Areas and Case Studies

Industry Applications:

- Manufacturing (assembly lines, quality control)

- Energy (power plants, renewable energy systems)

- Process Control (chemical, oil, and gas industries)

- Water/Wastewater Management

Case Study:

A leading automotive manufacturer integrated the DSAI130D into its assembly line to monitor torque sensors on robotic welders. The module’s 16-bit resolution and real-time diagnostics reduced sensor calibration errors by 45%, improving product quality and line efficiency by 20%.

A leading automotive manufacturer integrated the DSAI130D into its assembly line to monitor torque sensors on robotic welders. The module’s 16-bit resolution and real-time diagnostics reduced sensor calibration errors by 45%, improving product quality and line efficiency by 20%.

5. Competitor Comparison

Compared to similar analog input modules, the DSAI130D offers:

- Superior Noise Immunity: 50% higher EMI/RFI protection than standard modules.

- Faster Configuration: Predefined input ranges and digital commissioning tools cut setup time by 25%.

- Extended Temperature Range: Operates reliably in extreme conditions (-40°C to +70°C), surpassing most competitors’ 0–50°C limits.

DSAI130D

6. Selection Recommendations

- Compatibility: Ensure compatibility with your PLC system (e.g., ABB AC 800M/800XA).

- Environment: Choose the DSAI130D for harsh environments (high temperature, humidity, or vibrations).

- Scalability: Opt for 8-channel configuration for cost-effective expansion of small to medium-scale systems.

- Budget: Balance precision (16-bit) and cost—competitive pricing for high-performance requirements.

7. Precautions

- Installation: Follow ABB’s wiring guidelines (shielded cables for analog signals) to prevent noise interference.

- Voltage Check: Verify 24 V DC supply stability to avoid module damage.

- Maintenance: Regularly update firmware (via ABB’s Control Builder M software) for optimal performance.

- Safety: Disconnect power before module replacement; comply with IEC 61131-3 safety standards.