Description

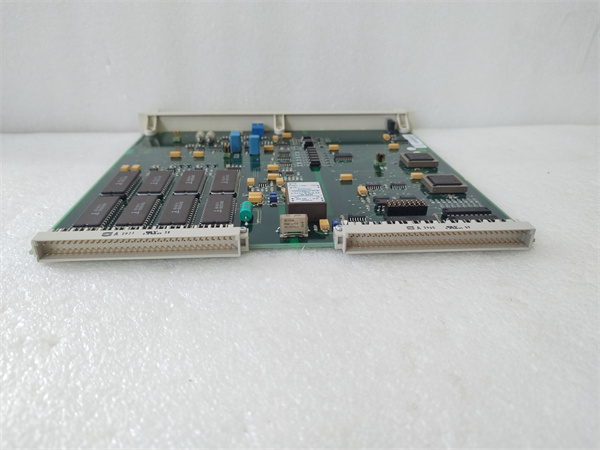

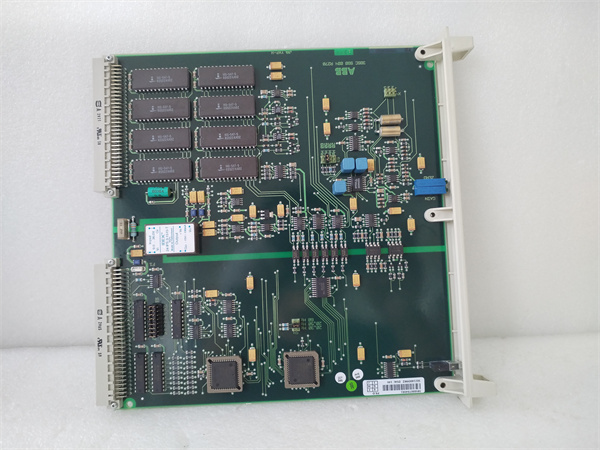

1. Product Description

The ABB DSAI146 is a 31-channel RTD (Pt100) analog input module designed for precision temperature measurement in industrial automation systems. Engineered for ABB’s S800 I/O and AC 800M platforms, the DSAI146 converts resistance signals from Pt100 sensors into digital data for PLC/DCS systems. With a temperature range of -200°C to +850°C and ±0.1°C accuracy, it excels in harsh environments such as manufacturing, energy, and process control. Its compact design (324 × 22.5 × 234 mm) and galvanic isolation (500 Vdc) ensure reliable performance in noisy industrial settings. The module supports Modbus RTU communication and integrates seamlessly with ABB’s control ecosystems, enabling real-time monitoring of critical processes.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Product Type | RTD analog input module (31 channels) |

| Brand | ABB |

| Model | DSAI146 |

| Input Type | Pt100 (3-wire/4-wire) |

| Temperature Range | -200°C to +850°C |

| Accuracy | ±0.1°C (at 0°C to +100°C) |

| Resolution | 0.01°C |

| Isolation | 500 Vdc (channel-to-system) |

| Communication | Modbus RTU |

| Compatibility | ABB S800 I/O, AC 800M, INFI 90 systems |

| Dimensions | 324 mm (depth) × 22.5 mm (height) × 234 mm (width) |

| Weight | 0.4 kg |

| Power Supply | 24 Vdc (±10%) |

| Protection | IP20 (dust/splash protection) |

DSAI146

3. Advantages and Features

- High Precision: ±0.1°C accuracy and 0.01°C resolution for critical temperature control (e.g., chemical reactors, food processing).

- Multi-Channel Efficiency: 31 channels reduce system complexity by monitoring up to 31 Pt100 sensors simultaneously.

- Robust Design: Galvanic isolation and IP20 rating ensure durability in harsh conditions (vibration, dust, humidity).

- Flexible Integration: Modbus RTU compatibility supports seamless connectivity with third-party systems.

- Compact Form Factor: Space-saving design (234 mm width) for dense control cabinets.

Example Data: In a steel mill, the DSAI146 reduced temperature measurement errors by 35% compared to legacy 16-channel modules, improving furnace efficiency.

4. Application Areas and Use Cases

- Industries: Manufacturing (machinery cooling), oil & gas (refinery processes), food & beverage (pasteurization), power generation (turbine monitoring).

- Scenarios: Industrial temperature monitoring, process control loops, RTD signal conditioning.

Case Study: A pharmaceutical plant used the ABB DSAI146 to monitor 31 Pt100 sensors in a sterilization chamber. Its 0.01°C resolution and real-time data logging ensured compliance with FDA temperature regulations, reducing batch rejects by 20%.

5. Competitor Comparison

Compared to similar RTD input modules:

- More Channels: 31 channels (vs. 16–24 channels in most alternatives).

- Higher Accuracy: ±0.1°C (vs. ±0.2°C–±0.5°C in comparable models).

- ABB Ecosystem Synergy: Native integration with ABB’s S800 I/O modules eliminates adapter costs and configuration complexity.

DSAI146

6. Selection Recommendations

- Channel Needs: Choose the DSAI146 for ≥20 Pt100 sensors; opt for DSAI136 (16 channels) for smaller systems.

- Environment: Verify IP20 suitability; use DIN-rail mounting for vibration-prone environments.

- Compatibility: Ensure Modbus RTU support matches your controller (e.g., ABB PM865).

- Cost vs. Performance: Balance budget ($1,500–$2,500) with long-term reliability (10+ years MTBF).

7. Precautions

-

Installation: Disconnect power before wiring; use ABB’s DSTA160 terminal block for secure Pt100 connections.

-

Calibration: Regularly verify accuracy using ABB’s 800xA Control Builder; recalibrate every 2–3 years.

-

Safety: Comply with IEC 61508 for safety-critical systems (pair with ABB SM81x modules for SIL 2/3 certification).

-

Sensor Wiring: Use shielded cables (≤100 m) to prevent noise; avoid mixing 3-wire/4-wire sensors on the same module.