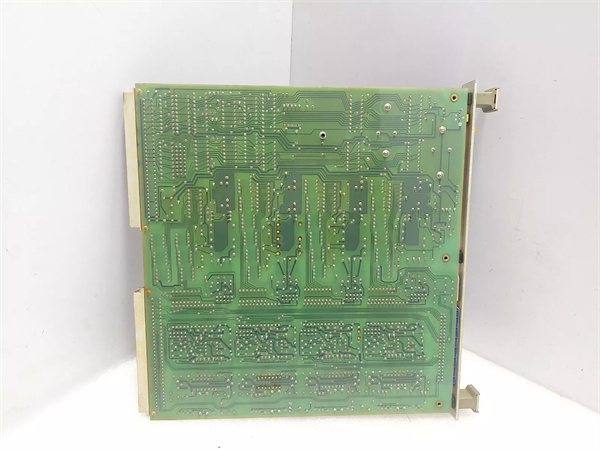

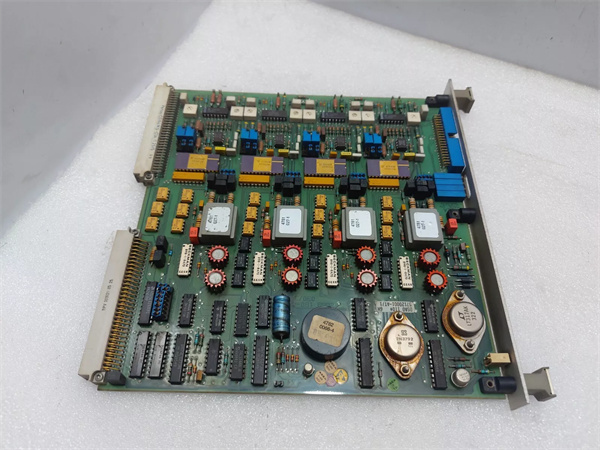

Description

1. Product Description

The ABB DSAO110 is a high-precision 4-channel analog output module designed for industrial automation and process control systems. Engineered for ABB’s S800 I/O and AC 800M platforms, the DSAO110 converts digital signals from PLCs or DCS systems into proportional analog voltage (0–±10 V) or current (0–±20 mA, 4–20 mA) outputs. Its channel-by-channel galvanic isolation (500 Vdc) ensures immunity to electrical noise, making it ideal for harsh environments in manufacturing, energy, and water treatment. The module supports on-line replacement and integrates seamlessly with ABB’s control ecosystems, delivering reliable performance for critical processes.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Product Type | Analog output module (4 channels) |

| Brand | ABB |

| Model | DSAO110 |

| Output Range | Voltage: 0–±10 V; Current: 0–±20 mA, 0–±10 mA, 4–20 mA (software-configurable) |

| Accuracy | ±0.05% full scale |

| Isolation | 500 Vdc (channel-to-channel and channel-to-system) |

| Resolution | 12 bits (including sign) |

| Compatibility | ABB S800 I/O, AC 800M, and INFI 90 systems |

| Dimensions | 209.7 mm (depth) × 18 mm (height) × 225 mm (width) |

| Weight | 0.595 kg |

| Power Supply | 24 Vdc |

| Certifications | CE, RoHS (exempt per ABB’s declaration for industrial control systems) |

DSAO110

3. Advantages and Features

- Precision Control: ±0.05% accuracy ensures stable process regulation in applications like temperature and pressure control.

- Galvanic Isolation: Four isolated channels prevent cross-interference, enhancing system reliability.

- Flexible Outputs: Supports both voltage and current outputs, adaptable to diverse industrial devices (valves, actuators, sensors).

- Compact Design: Space-saving form factor (225 mm width) for dense control cabinets.

- Easy Maintenance: Hot-swap capability reduces downtime; front-panel adjustments simplify calibration.

Example Data: In a chemical plant, the DSAO110 reduced output drift by 40% compared to non-isolated modules, improving batch process consistency.

4. Application Areas and Use Cases

- Industries: Manufacturing, oil & gas, water treatment, power generation.

- Scenarios: Process control loops, actuator/solenoid valve regulation, analog signal distribution.

Case Study: A food processing facility used the ABB DSAO110 to control four heating valves in a pasteurization line. The module’s 0.05% accuracy and channel isolation minimized temperature variations, increasing product yield by 12%.

5. Competitor Comparison

Compared to similar 4-channel analog output modules:

- Superior Isolation: 500 Vdc channel isolation (vs. 250 Vdc in most alternatives).

- Wider Output Range: Supports ±10 V/±20 mA (vs. limited single-range options).

- ABB Ecosystem Integration: Native compatibility with ABB’s S800 I/O modules reduces configuration complexity and adapter costs.

DSAO110

6. Selection Recommendations

- Channel Requirements: Ensure 4 channels meet your application’s I/O needs (consider DSAO120A for expanded features).

- Output Type: Choose voltage/current based on field devices (e.g., 4–20 mA for sensors with elevated zero).

- Environment: Verify IP ratings (IP20 standard) for dust/humidity; use DIN-rail mounting for vibration-prone settings.

- Budget: Balance cost ($300–$600) with long-term reliability (10+ years operational life).

7. Precautions

-

Installation: Disconnect power and process wiring before module replacement; use the DSTA160 terminal block for secure connections.

-

Calibration: Use ABB’s engineering tools (e.g., 800xA Control Builder) for channel adjustments; reference S100 I/O hardware manuals.

-

Safety: Ensure compliance with IEC 61508 for safety-critical systems (pair with SM81x modules for SIL 2/3 certification).

-

Compatibility: Avoid mixing with non-ABB modules; confirm firmware compatibility with your controller (e.g., PM865K01).