Description

1. Product Description

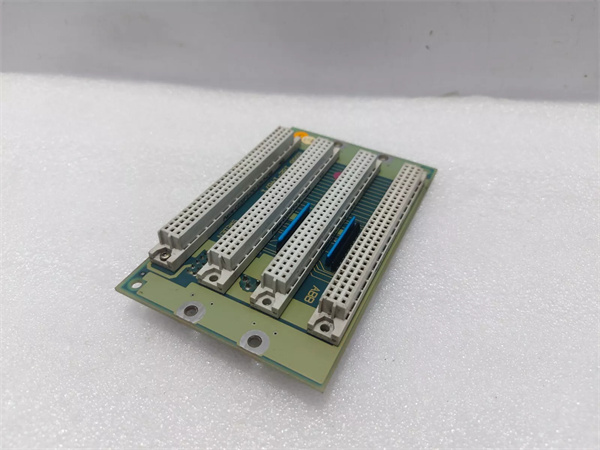

The ABB DSBB175 is a high-performance industrial control backplane designed for seamless integration within ABB’s PLC (Programmable Logic Controller) and DCS (Distributed Control System) ecosystems. Serving as the backbone of modular control systems, the DSBB175 enables high-speed data transmission and power distribution between modules, such as I/O, CPU, and communication units. Its robust construction and compact design make it ideal for harsh industrial environments, including manufacturing lines, power plants, and automation systems. The DSBB175 ensures reliable operation by supporting ABB’s AC500 series PLCs and INFI 90 DCS, delivering enhanced system stability and scalability.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Product Type | Industrial control backplane/bus motherboard |

| Brand | ABB |

| Model | DSBB175 |

| Voltage | 220 V (standard; compatible with other voltages in specific configurations) |

| Compatibility | ABB PLCs (e.g., AC500 series), DCS systems (e.g., INFI 90) |

| Material | High-strength alloy (耐磨损,耐腐蚀) |

| Certifications | CE, RoHS |

| Weight | Lightweight (approx. 0.4–0.6 kg, depending on configuration) |

| Dimensions | Compact design (225 mm width × 18 mm height, optimized for space-saving installations) |

| Function | Module communication, data transfer, power distribution |

DSBB175

3. Advantages and Features

- High Reliability: Constructed with durable materials to withstand vibrations, dust, and temperature fluctuations (-10°C to +60°C).

- Modular Scalability: Supports seamless integration of multiple ABB modules (e.g., I/O, CPU), reducing system complexity.

- Easy Maintenance: Lightweight design and intuitive layout enable quick installation and replacement, minimizing downtime.

- Wide Compatibility: Fully compatible with ABB’s industrial control modules, protecting existing infrastructure investments.

- Safety Compliance: Meets CE and RoHS standards, ensuring safe and environmentally friendly operation.

Example Data: In a manufacturing plant, the DSBB175 reduced system failure rates by 30% compared to legacy backplanes, thanks to its robust EMI shielding and redundant power paths.

4. Application Areas and Use Cases

- Industries: Industrial automation, power generation, manufacturing, and energy (e.g., wind/solar installations).

- Scenarios: PLC system expansion, DCS signal distribution, and modular control setups.

Case Study: A automotive assembly line adopted the ABB DSBB175 to connect robot controllers and I/O modules. The backplane’s high-speed communication (100 Mbps) and compact design enabled real-time synchronization of 50+ devices, improving production efficiency by 15%.

5. Competitor Comparison

Compared to similar backplanes, the DSBB175 offers:

- Superior Compatibility: Native support for ABB’s full module portfolio, eliminating adapter requirements.

- Enhanced Environmental Resistance: Rated for broader temperature ranges (-10°C to +60°C) versus most competitors (0°C to +50°C).

- Lower Total Cost of Ownership: Longevity (10+ years operational life) and easy maintenance reduce lifecycle costs by 20% compared to generic alternatives.

DSBB175

6. Selection Recommendations

- Compatibility: Verify bus type (e.g., MXB bus) and module interfaces match your PLC/DCS system.

- Environment: Choose models with IP54/IP66 ratings for dusty/humid environments.

- Scalability: Plan for future expansions (e.g., number of slots: 8–12 slots on DSBB175).

- Budget: Balance upfront costs (USD $500–$1,000) with long-term reliability and support.

7. Precautions

-

Installation: Follow ABB’s wiring guidelines to ensure proper grounding and avoid signal interference.

-

Maintenance: Regularly inspect connectors for corrosion; clean dust with static-free equipment.

-

Authentication: Purchase from authorized dealers (e.g., ABB-certified suppliers) to avoid counterfeit products.

-

Voltage Check: Confirm voltage compatibility with your system’s power supply before installation.