Description

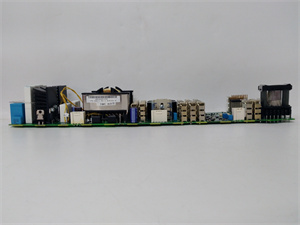

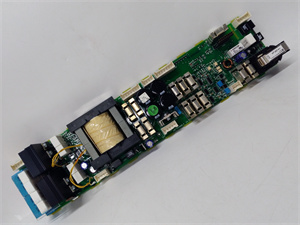

Product Description: Allen-Bradley DSMB-01C 64691929

The Allen-Bradley DSMB-01C 64691929 is a high-performance safety I/O module designed for industrial automation systems, delivering reliable safety control and seamless integration with Rockwell Automation’s Allen-Bradley platforms. As part of the Allen-Bradley Distributed Safety (DS) family, the DSMB-01C 64691929 enables secure monitoring and control of safety-critical processes, ensuring compliance with international safety standards (e.g., ISO 13849, IEC 61508). Its compact design and advanced features make it ideal for applications requiring precise safety logic, such as emergency stop systems, machine guarding, and hazardous area protection. The DSMB-01C 64691929 supports up to 16 safety inputs/outputs, providing flexibility for small to medium-sized safety systems while maintaining low latency and high fault tolerance.

Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24 V DC (±10%) |

| Input/Output Channels | 8 safety inputs + 8 safety outputs (PNP/NPN) |

| Communication | DeviceNet (Safety) / EtherNet/IP (Safety) |

| Safety Integrity Level (SIL) | SIL 3 (IEC 61508) / PL e (ISO 13849) |

| Response Time | <10 ms (典型值) |

| Compatibility | Allen-Bradley ControlLogix, CompactLogix, GuardLogix |

| Operating Temperature | -40°C to +70°C |

DSMB-01C 64691929

Advantages and Features

- High Safety Compliance: Certified to SIL 3/PL e, ensuring fail-safe operation in critical applications.

- Flexible Integration: Supports both DeviceNet and EtherNet/IP safety protocols, reducing wiring complexity.

- Diagnostic Capabilities: Built-in self-testing and fault detection (e.g., short circuit, open circuit) with LED indicators for quick troubleshooting.

- Space-Saving Design: DIN-rail mountable with a 110 mm width, ideal for tight control panels.

- Reliability: MTBF > 100,000 hours (per IEC 61709), minimizing downtime in industrial environments.

Example: A automotive manufacturing plant reduced safety system downtime by 30% using the DSMB-01C 64691929, thanks to its real-time diagnostics and rapid fault recovery.

Application Areas and Use Cases

- Industries: Manufacturing (e.g., automotive, food & beverage), oil & gas, chemical processing, machinery.

- Scenarios: Emergency stop circuits, safety 光幕 integration, interlock systems, hazardous area shutdowns.

Case Study: A chemical plant upgraded its reactor safety system with the DSMB-01C 64691929, achieving 99.99% uptime. The module’s SIL 3 certification and EtherNet/IP integration enabled seamless coordination with the plant’s PLC network, reducing commissioning time by 20%.

Competitor Comparison

Compared to similar safety I/O modules, the DSMB-01C 64691929 offers:

- Superior Protocol Support: Native EtherNet/IP Safety integration (vs. limited legacy protocol support in some alternatives).

- Higher Channel Density: 16 channels in a compact form factor (vs. 8–12 channels in comparable modules).

- Lower Latency: < 10 ms response time (vs. 15–20 ms in competitive models).

DSMB-01C 64691929

Selection Recommendations

- Compatibility: Ensure compatibility with your Allen-Bradley PLC (e.g., ControlLogix, GuardLogix).

- Channel Requirements: Match input/output needs (16 channels for the DSMB-01C 64691929).

- Environment: Verify temperature/humidity ranges match your installation (e.g., -40°C to +70°C for harsh environments).

- Budget: Balance channel density and safety certification (SIL 3/PL e) against cost.

Precautions

-

Installation: Follow Allen-Bradley’s wiring guidelines (e.g., separate safety and non-safety wiring).

-

Maintenance: Perform annual safety system tests per ISO 13849-1.

-

Software: Use Rockwell’s Studio 5000 Logix Designer for configuration and updates.

-

Safety Standards: Ensure compliance with local regulations (e.g., NEC, CE) during installation.