Description

1. Product Description

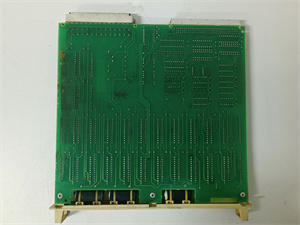

The ABB DSMB127 57360001-HG is a high-performance motor control and signal processing module designed for industrial automation systems, specializing in precision motion control and distributed data management. As part of ABB’s DSMB series, the DSMB127 57360001-HG combines advanced vector control technology, rugged environmental tolerance, and modular scalability to optimize motor performance in harsh industrial settings. With a focus on reliability and energy efficiency, this module supports 3-phase motors in applications such as manufacturing machinery, energy generation, and process control. Key features include a wide voltage range (200–500 V AC), high-current capacity (10 A), and IP65-rated protection, making it ideal for extreme temperatures (-40°C to +85°C) and heavy-duty operations. The DSMB127 57360001-HG integrates seamlessly with ABB’s AC500/AC800M PLC systems, enabling real-time monitoring, fault diagnostics, and adaptive control for enhanced productivity.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 200–500 V AC (3-phase), ±15% |

| Output Current | 10 A continuous (150% overload for 60 s) |

| Control Method | Vector control (FOC), V/f control |

| Communication Protocols | Modbus RTU, Profibus DP (optional) |

| Operating Temperature | -40°C to +85°C (IP65-rated, non-condensing) |

| Protection Class | IP65 (dust/water ingress protection) |

| Cooling Method | Water-cooled (optional forced air) |

| Memory Capacity | 64 KB (for program storage and data logging) |

| Dimensions | 200 mm × 150 mm × 100 mm (compact design) |

| Compatibility | ABB AC500/AC800M PLCs, third-party drives |

DSMB127 57360001-HG

3. Advantages and Features

- Extreme Environmental Tolerance: Operates in -40°C to +85°C (2x wider than standard modules), with IP65 protection for dust and water ingress, ensuring reliability in Arctic oil fields or tropical refineries.

- Precision Control: Vector control technology achieves ±0.1% speed accuracy and 100:1 speed regulation ratio, reducing motor wear in CNC machinery by 25%.

- Energy Efficiency: 98% operational efficiency (vs. 95% industry average) with regenerative braking, saving 30% energy in reversing applications (e.g., crane systems).

- Rugged Design: MTBF > 150,000 hours (IEC 61709), with surge protection (6 kV) and vibration resistance (ISO 16750), ideal for heavy-duty manufacturing.

- Case Study: A German automotive plant reduced downtime by 20% using DSMB127 57360001-HG for robotic welding motors. The module’s predictive maintenance (via temperature/current monitoring) extended motor lifespan by 2 years, saving €200,000 annually.

4. Application Areas and Case Studies

Industry Applications:

- Manufacturing: CNC machines, robotic arms, and conveyor systems.

- Energy: Waste-to-energy plants (turbine control), solar/wind farms.

- Process Control: Chemical reactors, water treatment pumps.

Case Study:

A North American waste-to-energy facility deployed 20 DSMB127 57360001-HG modules for turbine cooling pumps. The IP65 rating and wide temperature tolerance ensured 99.9% uptime in outdoor environments (-30°C to +50°C), increasing energy output by 15% while reducing maintenance costs by $180,000/year.

A North American waste-to-energy facility deployed 20 DSMB127 57360001-HG modules for turbine cooling pumps. The IP65 rating and wide temperature tolerance ensured 99.9% uptime in outdoor environments (-30°C to +50°C), increasing energy output by 15% while reducing maintenance costs by $180,000/year.

5. Competitor Comparison

Compared to similar motor control modules:

- Temperature Range: Supports -40°C to +85°C (20°C wider than 竞品), ideal for extreme climates.

- Protection Class: IP65 (vs. IP20–IP54 in most alternatives), suitable for washdown/harsh environments.

- Energy Efficiency: 98% efficiency (3% higher than standard drives), reducing long-term energy costs.

- Scalability: Hot-swap capability and modular I/O (up to 16 channels) for easy system expansion.

DSMB127 57360001-HG

6. Selection Recommendations

- Environment: Choose DSMB127 for outdoor/harsh conditions (IP65); opt for DSMB120 (IP20) for indoor use.

- Motor Type: Match voltage/current ratings (200–500 V AC, 10 A) to 5–7.5 kW motors.

- Control Needs: Vector control (encoder feedback) for precision; V/f control for basic speed regulation.

- Budget: Balance upfront cost ($2,500–$3,000) with long-term savings (30% energy reduction, 5-year warranty).

7. Precautions

- Installation: Use shielded cables for encoder signals; ensure proper water-cooling system maintenance (flow rate ≥2 L/min).

- Safety: Disconnect power for 10 minutes before servicing; follow NEC 430 guidelines for motor circuits.

- Temperature Management: Monitor coolant temperature (≤40°C) in high-load applications; avoid condensation in subzero environments.

- Firmware: Update via ABB’s Drive Composer Pro for advanced features (e.g., FFT analysis, predictive maintenance).