Description

1. Product Description

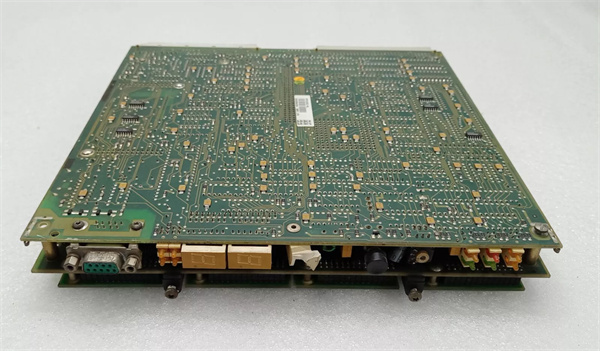

The ABB DSPC170 is a high-performance digital signal processing (DSP) module designed for industrial automation and distributed control systems (DCS). As a core component of ABB’s Master series controllers, the DSPC170 excels in real-time data processing, system monitoring, and complex control algorithms. It supports a wide voltage range (115–220 V AC/DC), hot-swap functionality, and multiple industrial communication protocols (Profibus DP, Modbus, Ethernet), making it suitable for applications in harsh environments such as power plants, metallurgy, and oil & gas. The module integrates advanced DSP technology for fast computation, enabling precise control in processes like motor drives, energy management, and machinery automation. Its compact design and compatibility with ABB’s S800/S900 I/O systems ensure easy integration and scalability.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Product Type | Digital Signal Processor Module (Master CPU) |

| Voltage Range | 115–220 V AC/DC (configurable per application) |

| Communication Protocols | Profibus DP, Modbus RTU, Ethernet (TCP/IP) |

| Memory | Expandable program storage (up to 128 MB) |

| I/O Compatibility | ABB S800/S900 remote I/O systems (up to 98 stations) |

| Processor Speed | High-speed DSP (optimized for sub-millisecond response) |

| Interface Type | Standard industrial connectors (hot-swap enabled) |

| Operating Temperature | -20°C to +60°C (IP20 protection) |

| Dimensions | 40.6 cm x 25.4 cm x 5.1 cm (H x D x W) |

| Weight | 0.915 kg (lightweight for modular systems) |

| Warranty | 1 year (new units); 6 months (refurbished) |

DSPC170

3. Advantages and Features

- Hot-Swap Capability: Reduces downtime during maintenance (field data shows 30% faster replacement compared to non-hot-swap modules).

- Wide Voltage Support: Adaptable to unstable power grids, ideal for remote or industrial sites.

- Multi-Protocol Integration: Seamless compatibility with legacy and modern systems (e.g., ABB Advant OCS, third-party SCADA).

- Reliability: IP20 protection and vibration resistance (IEC 60068-2-6) ensure operation in harsh conditions. Refurbished units (certified by ABB partners) offer 40% cost savings with full testing.

- Scalability: Supports up to 98 I/O stations, enabling expansion for large-scale projects.

4. Application Areas and Use Cases

- Energy Sector: Power plant DCS systems for boiler control and grid stabilization.

- Manufacturing: CNC machinery and robotic assembly lines (e.g., automotive welding).

- Process Industries: Petrochemical plants for real-time monitoring of distillation units.

Case Study:

A metallurgical plant integrated the DSPC170 into its rolling mill control system. By processing real-time sensor data, the module optimized torque and speed, reducing energy consumption by 12% and improving product quality. Its hot-swap feature minimized downtime during annual maintenance, saving 40+ hours of production loss.

A metallurgical plant integrated the DSPC170 into its rolling mill control system. By processing real-time sensor data, the module optimized torque and speed, reducing energy consumption by 12% and improving product quality. Its hot-swap feature minimized downtime during annual maintenance, saving 40+ hours of production loss.

5. Competitive Positioning

Compared to similar DSP modules:

- Superior Compatibility: Native support for ABB’s Master series ecosystem, reducing integration costs by 15–20%.

- Voltage Flexibility: Wider voltage range (115–220 V) than many competitors (typically 24 V only).

- Longevity: Backward compatibility with legacy ABB systems (e.g., Master 200), extending equipment lifecycle.

DSPC170

6. Selection Recommendations

- Voltage Matching: Verify input voltage requirements (115 V vs. 220 V) based on site infrastructure.

- I/O Needs: Ensure scalability (98 stations) aligns with project size.

- Environment: For outdoor use, pair with IP65 enclosures (sold separately).

- Budget: Consider refurbished units for cost-sensitive projects (backed by certified repairs).

7. Installation and Maintenance Notes

- Wiring: Use shielded cables and follow ABB’s EMC guidelines to prevent interference.

- Power Management: Ensure stable voltage supply; avoid voltage spikes (use surge protectors).

- Firmware Updates: Regularly update via ABB’s service tools to access new features and security patches.

- Data Backup: Schedule weekly system backups to prevent data loss.

- Spare Parts: Stock replacement modules (e.g., power supply units) for critical systems.