Description

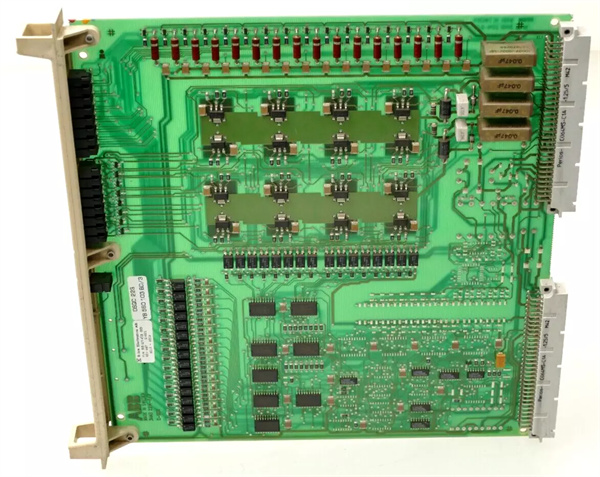

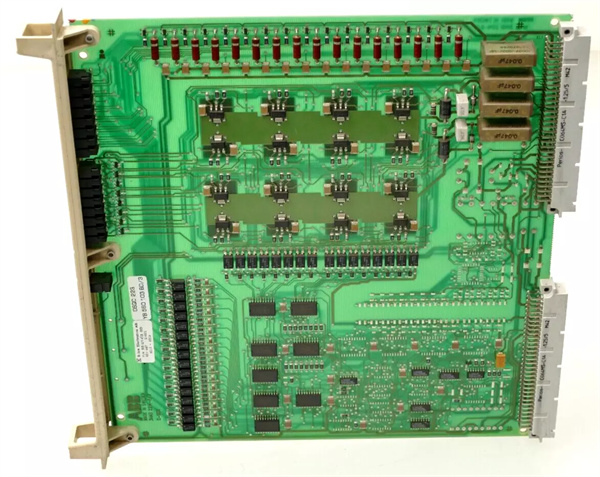

ABB DSQC223 YB560103-BD: High-Performance Digital I/O Module for Industrial Automation

1. Product Description

The DSQC223 YB560103-BD serves as a critical interface between industrial robots, sensors, and actuators, enabling precise control of digital signals. With 16 digital inputs and 16 digital outputs, it supports real-time communication and efficient data handling, making it suitable for assembly lines, material handling, and quality control systems. Its compact design and rugged construction (IP20 防护等级) ensure long-term operation in dusty, humid, or high-vibration settings. Key advantages include:

- High Reliability: Certified for 100,000+ hours of MTBF (mean time between failures).

- Easy Integration: Plug-and-play compatibility with ABB’s robot controllers and standardized programming interfaces.

- Energy Efficiency: Low power consumption (≤5W) reduces operational costs.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24V DC (±10%) |

| Current per Channel | Input: 4 mA; Output: 0.5 A (resistive load) |

| Interface | Serial Communication (DeviceNet/ProfiBus) |

| Compatibility | ABB IRC5, IRC5 Compact, and YuMi controllers |

| Number of I/O Channels | 16 inputs + 16 outputs (optocoupler-isolated) |

| Operating Temperature | -20°C to +55°C |

| Dimensions | 150 mm × 90 mm × 50 mm |

DSQC223 YB560103-BD

3. Advantages and Features

- Industry-Leading Durability: Built with reinforced components and surge protection, the DSQC223 YB560103-BD withstands voltage spikes and electromagnetic interference (EMI).

- Flexible Configuration: Programmable input/output delays (0–250 ms) allow customization for specific process requirements.

- Remote Monitoring: Integrated diagnostics provide real-time status updates, minimizing downtime.

- Case Study: A automotive manufacturer reduced maintenance costs by 30% using the DSQC223 YB560103-BD in welding robots, thanks to its extended lifespan and error-free signal transmission.

4. Application Areas and Cases

- Industries: Automotive, electronics, metal fabrication, and logistics.

- Scenarios: Robot cell control, conveyor systems, and safety interlock systems.

- Application Case: A food packaging plant integrated the DSQC223 YB560103-BD into its robotic palletizing line, achieving 99.9% uptime and faster changeovers due to its quick-replace design.

5. Competitor Comparison

Compared to similar modules, the DSQC223 YB560103-BD offers:

- Superior Compatibility: Native support for ABB’s robot programming suite (RAPID), reducing integration complexity.

- Longer Warranty: 2-year warranty (vs. 1-year average in the market).

- Space Efficiency: 20% smaller form factor than legacy models, ideal for compact workcells.

-

DSQC223 YB560103-BD

6. Selection Recommendations

- Compatibility: Ensure alignment with your ABB robot controller (e.g., IRC5).

- Environment: Verify temperature and humidity ranges match your facility’s conditions.

- Scalability: Pair with ABB’s DSQC651 or DSQC377 modules for larger I/O systems.

- Budget: Balance cost with long-term reliability—invest in spare modules for critical operations.

7. Precautions

- Installation: Follow ABB’s ESD (electrostatic discharge) guidelines; use anti-static gloves.

- Wiring: Secure connections to prevent vibration-induced loosening.

- Maintenance: Schedule annual inspections; clean dust from vents using compressed air.

- Software: Update firmware regularly via ABB’s RobotStudio® for optimal performance.