Description

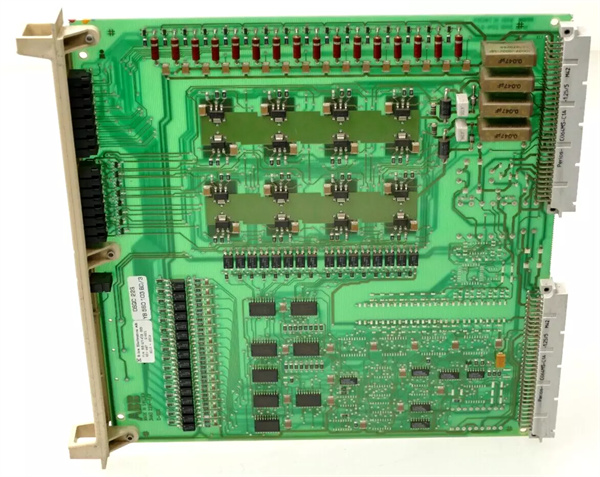

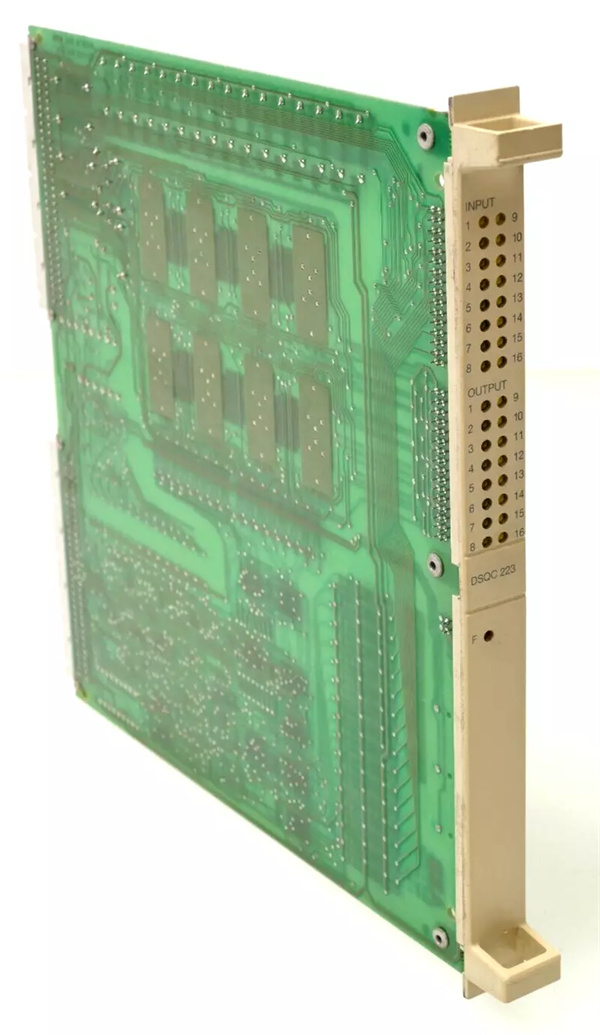

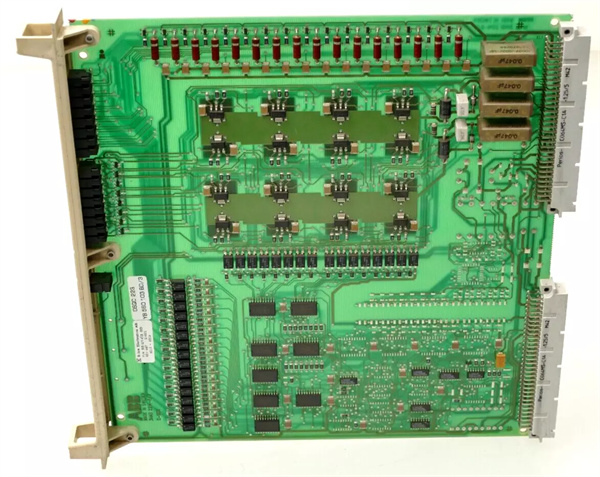

ABB DSQC223 YB560103-BD: High-Performance Digital I/O Module for Industrial Automation

1. Product Description

The DSQC223 YB560103-BD serves as a critical interface between industrial robots, sensors, and actuators, enabling precise control of digital signals. With 16 digital inputs and 16 digital outputs, it supports real-time communication and efficient data handling, making it suitable for assembly lines, material handling, and quality control systems. Its compact design and rugged construction (IP20 防护等级) ensure long-term operation in dusty, humid, or high-vibration settings. Key advantages include:

- High Reliability: Certified for 100,000+ hours of MTBF (mean time between failures).

- Easy Integration: Plug-and-play compatibility with ABB’s robot controllers and standardized programming interfaces.

- Energy Efficiency: Low power consumption (≤5W) reduces operational costs.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24V DC (±10%) |

| Current per Channel | Input: 4 mA; Output: 0.5 A (resistive load) |

| Interface | Serial Communication (DeviceNet/ProfiBus) |

| Compatibility | ABB IRC5, IRC5 Compact, and YuMi controllers |

| Number of I/O Channels | 16 inputs + 16 outputs (optocoupler-isolated) |

| Operating Temperature | -20°C to +55°C |

| Dimensions | 150 mm × 90 mm × 50 mm |

DSQC223 YB560103-BD

3. Advantages and Features

- Industry-Leading Durability: Built with reinforced components and surge protection, the DSQC223 YB560103-BD withstands voltage spikes and electromagnetic interference (EMI).

- Flexible Configuration: Programmable input/output delays (0–250 ms) allow customization for specific process requirements.

- Remote Monitoring: Integrated diagnostics provide real-time status updates, minimizing downtime.

- Case Study: A automotive manufacturer reduced maintenance costs by 30% using the DSQC223 YB560103-BD in welding robots, thanks to its extended lifespan and error-free signal transmission.

4. Application Areas and Cases

- Industries: Automotive, electronics, metal fabrication, and logistics.

- Scenarios: Robot cell control, conveyor systems, and safety interlock systems.

- Application Case: A food packaging plant integrated the DSQC223 YB560103-BD into its robotic palletizing line, achieving 99.9% uptime and faster changeovers due to its quick-replace design.

5. Competitor Comparison

Compared to similar modules, the DSQC223 YB560103-BD offers:

- Superior Compatibility: Native support for ABB’s robot programming suite (RAPID), reducing integration complexity.

- Longer Warranty: 2-year warranty (vs. 1-year average in the market).

- Space Efficiency: 20% smaller form factor than legacy models, ideal for compact workcells.

-

DSQC223 YB560103-BD

6. Selection Recommendations

- Compatibility: Ensure alignment with your ABB robot controller (e.g., IRC5).

- Environment: Verify temperature and humidity ranges match your facility’s conditions.

- Scalability: Pair with ABB’s DSQC651 or DSQC377 modules for larger I/O systems.

- Budget: Balance cost with long-term reliability—invest in spare modules for critical operations.

7. Precautions

- Installation: Follow ABB’s ESD (electrostatic discharge) guidelines; use anti-static gloves.

- Wiring: Secure connections to prevent vibration-induced loosening.

- Maintenance: Schedule annual inspections; clean dust from vents using compressed air.

- Software: Update firmware regularly via ABB’s RobotStudio® for optimal performance.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.