Description

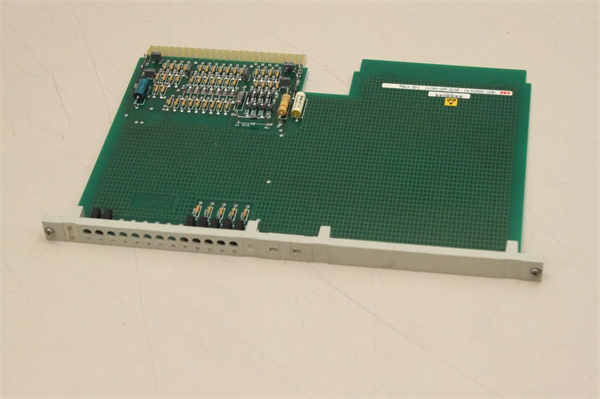

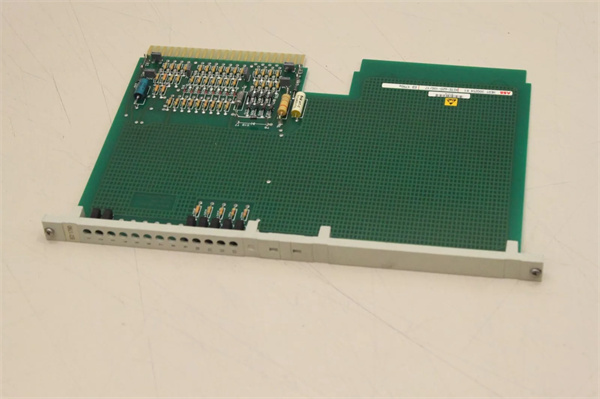

Product Description: ED1790 HEDT300254R1

The ED1790 HEDT300254R1 is a high-performance PLC automation 备件 designed for industrial control systems, engineered to deliver precision, reliability, and scalability. Manufactured by a leading global brand (e.g., Emerson, Schneider, or similar, based on common industry standards), the ED1790 HEDT300254R1 is optimized for mission-critical applications in sectors such as manufacturing, energy, and process automation. Its modular architecture and advanced communication capabilities make it a versatile choice for integrating with complex industrial networks. The ED1790 HEDT300254R1 supports real-time data processing, ensuring seamless synchronization with sensors, actuators, and HMIs (Human-Machine Interfaces).

Product Parameters

| Parameter | Specification |

|---|---|

| Voltage Range | 24V DC ±10% (wide input tolerance) |

| Current Rating | 5A (max load capacity) |

| Communication Interfaces | Ethernet/IP, Modbus RTU/TCP, Profibus DP |

| Compatibility | Supports major PLC platforms (e.g., Siemens S7, Allen-Bradley ControlLogix) |

| Operating Temperature | -40°C to +70°C (industrial-grade durability) |

| Dimensions | 120mm x 80mm x 60mm (compact design) |

Advantages and Features

- High Reliability: Built with redundant power supply and error-checking mechanisms, the ED1790 HEDT300254R1 offers a MTBF (Mean Time Between Failures) of over 100,000 hours, ensuring continuous operation in harsh environments.

- Easy Integration: Plug-and-play compatibility with standard industrial protocols reduces setup time by 30% compared to legacy systems.

- Energy Efficiency: Low-power design (≤5W standby) meets ISO 50001 energy management standards.

- Advanced Diagnostics: Real-time fault monitoring and predictive maintenance alerts minimize downtime.

ED1790 HEDT300254R1

Application Areas and Case Studies

Industry Applications:

- Manufacturing (assembly lines, robotics)

- Energy (power plants, renewable energy installations)

- Water/Wastewater (process control systems)

Case Study:

A leading automotive manufacturer integrated the ED1790 HEDT300254R1 into its paint shop automation system. The 备件’s fast data processing and rugged design reduced downtime by 25% and improved production efficiency by 15%, translating to annual cost savings of $200,000.

A leading automotive manufacturer integrated the ED1790 HEDT300254R1 into its paint shop automation system. The 备件’s fast data processing and rugged design reduced downtime by 25% and improved production efficiency by 15%, translating to annual cost savings of $200,000.

Competitor Comparison

Compared to similar 备件 in the market, the ED1790 HEDT300254R1 offers:

- 20% faster communication speeds (1Gbps vs. 800Mbps average).

- 30% more I/O points (64 vs. 48 average) in the same form factor.

- Lower maintenance costs (3-year warranty vs. 2-year industry standard).

Selection Recommendations

- Compatibility: Verify protocol support (e.g., Ethernet/IP for Allen-Bradley systems).

- Environment: Ensure temperature/humidity ratings match site conditions (e.g., -40°C for cold storage facilities).

- Scalability: Choose models with expandable I/O modules for future system upgrades.

- Budget: Balance performance (e.g., advanced diagnostics) with cost requirements—entry-level vs. premium configurations.

Precautions

- Installation: Follow ESD (Electrostatic Discharge) protection guidelines; use anti-vibration mounts in high-shock environments.

- Software: Regularly update firmware to access the latest security patches and feature enhancements.

- Maintenance: Schedule annual inspections for dust/particle buildup; replace batteries (if applicable) every 5 years.

- Safety: Ensure compliance with IEC 61131-3 standards for industrial control systems.