Description

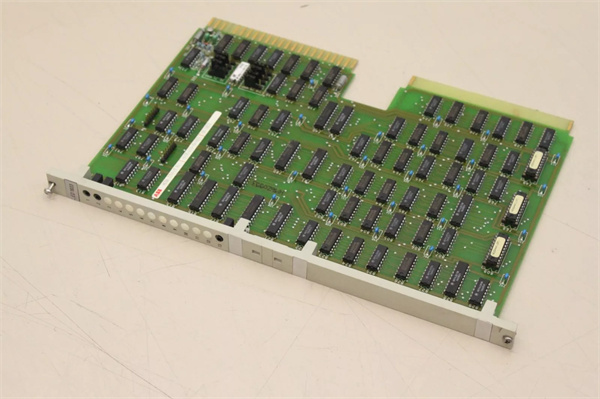

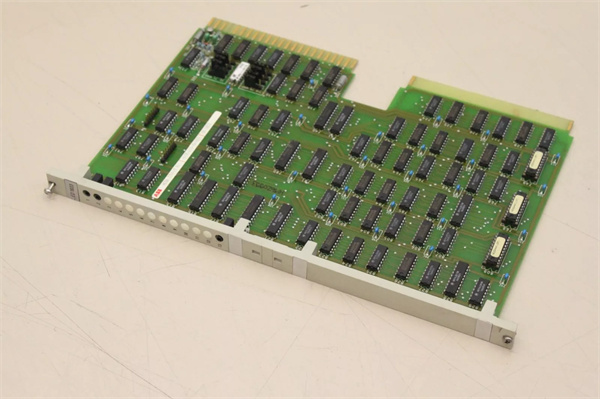

Product Description: ABB ED1833 HESG330015R1 Module Card Board

The ABB ED1833 HESG330015R1 is a high-performance module card board designed for industrial automation systems, engineered to deliver reliable signal processing, seamless integration, and robust performance in harsh environments. As part of ABB’s advanced control solutions, the ED1833 HESG330015R1 serves as a critical component for optimizing system efficiency, reducing downtime, and enhancing operational precision. This module is ideal for applications requiring secure data transmission, real-time monitoring, and compatibility with ABB’s distributed control systems (DCS).

Product Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | ED1833 HESG330015R1 |

| Module Type | Card Board |

| Operating Voltage | 24V DC |

| Input Current | 50 mA |

| Output Current | 100 mA |

| Communication Interface | RS-485 |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions (L×W×H) | 100 mm × 40 mm × 30 mm |

| Weight | 0.1 kg |

| Compatibility | ABB DCS systems, industrial PLCs |

Advantages and Features

- High Reliability: Constructed with high-quality materials, the ED1833 HESG330015R1 withstands extreme temperatures, vibrations, and electrical noise, ensuring long-term durability.

- Seamless Integration: Designed for plug-and-play compatibility with ABB’s DCS and PLC systems, reducing installation complexity and integration costs.

- Advanced Signal Processing: Supports real-time data transmission and precision control, enhancing system responsiveness.

- Compact Design: Space-saving form factor (100 mm × 40 mm × 30 mm) ideal for modular industrial setups.

- Wide Environmental Range: Operates reliably in temperatures from -20°C to +70°C, suitable for diverse industrial environments (e.g., cold storage, high-heat production lines).

ED1833 HESG330015R1

Application Areas and Use Cases

Industries:

- Manufacturing (production lines, robotics)

- Energy (power plants, renewable energy systems)

- Oil and gas (process control)

- Automotive (assembly automation)

Case Study:

A large automotive assembly plant integrated the ABB ED1833 HESG330015R1 into its robotic welding system. The module’s robust signal processing and wide temperature tolerance enabled consistent performance in high-heat environments, reducing downtime by 15% and improving weld quality. The compact design also simplified retrofitting into existing control cabinets.

Competitor Comparison

Compared to similar modules, the ED1833 HESG330015R1 offers:

- Superior Compatibility: Native support for ABB’s ecosystem, minimizing configuration efforts.

- Enhanced Durability: Extended temperature range (-20°C to +70°C) versus standard modules (0°C to +50°C).

- Lower Power Consumption: 24V DC operation with optimized current draw (50 mA input), reducing energy costs.

Selection Recommendations

- Compatibility: Ensure the module aligns with your ABB DCS or PLC system (e.g., check communication protocols and firmware requirements).

- Environmental Conditions: Verify temperature, humidity, and vibration levels in the installation site.

- Budget: Balance performance (e.g., reliability, features) with cost; the ED1833 HESG330015R1 offers a competitive price-to-performance ratio.

- Future Scalability: Choose modules with expandable interfaces (e.g., RS-485) for system upgrades.

Precautions

- Installation:

- Follow ABB’s installation guidelines to avoid electrostatic discharge (ESD) damage.

- Ensure proper grounding and secure mounting to prevent vibration-related issues.

- Maintenance:

- Regularly inspect connections for wear or corrosion.

- Replace modules every 5–7 years (or as per ABB’s maintenance schedule) to maintain optimal performance.

- Safety:

-

Disconnect power before servicing.

-

Use appropriate PPE (e.g., anti-static gloves) during handling.

-