Description

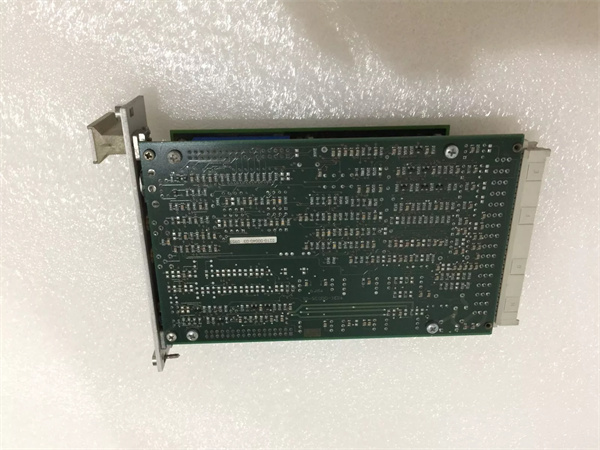

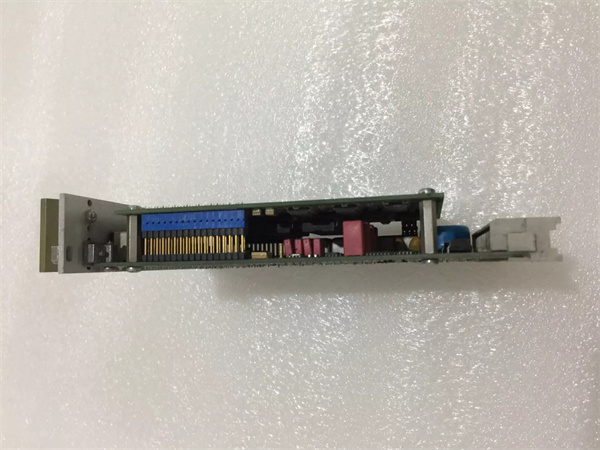

EPRO MMS6110 Dual-Channel Shaft Vibration Monitor

The EPRO MMS6110 is a high-precision industrial monitoring module designed for real-time detection of radial shaft vibrations in rotating machinery. As part of Emerson EPro’s MMS 6000 series, this dual-channel device leverages advanced eddy current technology to deliver reliable performance in critical applications such as power generation, petrochemical processing, and heavy manufacturing.

Product Parameters

| Parameter | Specification |

|---|---|

| Channels | Dual (independent vibration monitoring) |

| Sensor Type | Eddy current (e.g., PR642X series) |

| Measurement Range | Configurable based on sensor setup |

| Accuracy | ±1% of full scale (FS) |

| Input Voltage | 24V DC (±10%) |

| Output Signals | 4–20 mA (analog), RS232/485 (digital) |

| Frequency Response | 0–10 kHz |

| Operating Temperature | -25°C to +70°C |

| Dimensions | 191 x 128 x 31 mm |

| Weight | 0.4 kg |

EPRO MMS6110

Advantages and Characteristics

- Dual-Channel Flexibility: Simultaneously monitors two radial vibration axes, reducing hardware complexity.

- Non-Contact Eddy Current Technology: Minimizes wear and ensures continuous operation in harsh environments.

- Predictive Maintenance: Detects early signs of misalignment or bearing wear through real-time vibration analysis.

- Modular Design: Easily integrates with existing MMS 6000 systems and supports field upgrades.

- Enhanced Safety: Built-in self-diagnostic features and password-protected configurations prevent unauthorized changes.

Application Fields and Case Studies

- Power Generation: Turbine vibration monitoring to avoid catastrophic failures.

- Oil and Gas: Compressor and pump health assessment in refineries.

- Transportation: Rail vehicle axle vibration analysis for safety and efficiency.

Case Study: A power plant reduced maintenance costs by 15% using the EPRO MMS6110 to identify turbine blade imbalance, enabling targeted repairs before failures occurred.

Competitive Comparison

The EPRO MMS6110 stands out with:

- Wide Temperature Range: Operates reliably in extreme conditions (-25°C to +70°C).

- Dual-Channel Redundancy: Ensures continuous monitoring even if one channel fails.

- Advanced Signal Processing: Supports spectrum analysis for detailed machinery diagnostics.

EPRO MMS6110

Selection Recommendations

- Sensor Compatibility: Verify compatibility with PR642X-series sensors and CON0X1 preamplifiers.

- Environmental Requirements: Ensure the module’s temperature and humidity ratings match the installation site.

- System Integration: Consider expansion needs, as the MMS 6000 platform supports scalable monitoring networks.

Precautions

- Installation: Follow wiring diagrams carefully to avoid signal interference.

- Power Stability: Use a filtered 24V DC power supply to prevent voltage fluctuations.

- Calibration: Regularly calibrate sensors and modules to maintain measurement accuracy.