Description

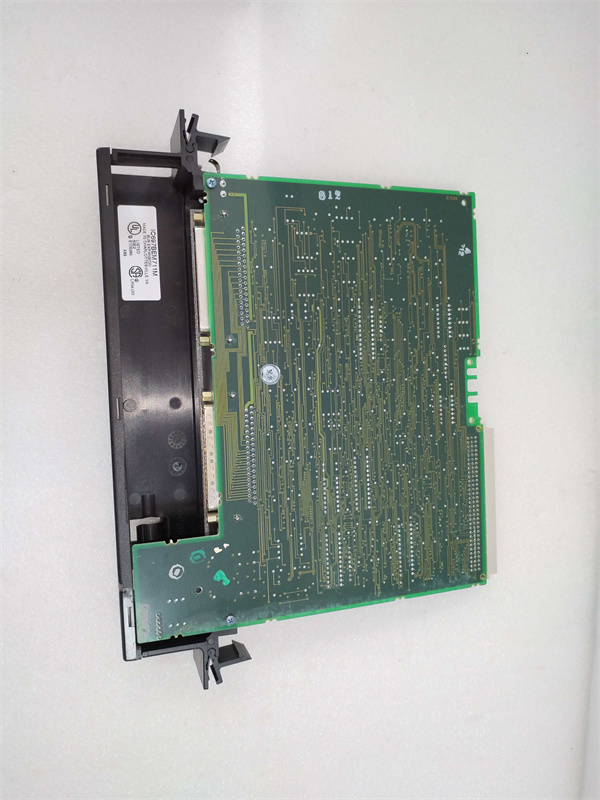

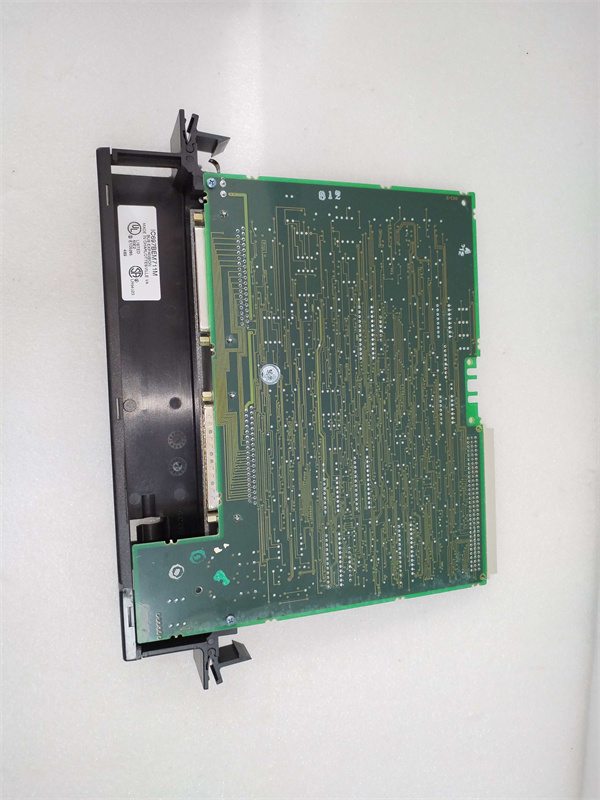

GE Fanuc IC697BEM711 Backplane Expansion Module

GE Fanuc IC697BEM711 is a versatile backplane expansion module designed for GE’s Series 90-70 PLC platform, enabling seamless integration of multiple I/O racks and peripherals. This module supports high-speed data transfer and redundancy configurations, making it ideal for complex industrial automation systems requiring scalability and reliability. With its compact design and advanced diagnostic capabilities, the IC697BEM711 simplifies system expansion while ensuring robust performance in harsh environments.

Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 24 VDC ±10% |

| Power Consumption | 3 W |

| Interface Type | GE Genius Bus (supports up to 16 modules per backplane) |

| Compatibility | GE Series 90-70 PLCs, Proficy Machine Edition software |

| Rack Expansion | Supports up to 4 additional I/O racks per controller |

| Redundancy Support | Hot-swap capable for dual-controller configurations |

| Operating Temperature | -40°C to 70°C |

| Dimensions | 150 mm x 100 mm x 60 mm |

| Weight | 0.4 kg |

| Isolation | 2,500 VDC between modules and ground |

IC697BEM711

Advantages and Features

-

Scalability and Flexibility:

- Expands system capacity by connecting up to 4 additional I/O racks, allowing for up to 256 I/O channels per controller.

- Supports mixed I/O configurations (analog, digital, and specialty modules) for diverse automation needs.

-

High-Speed Data Transfer:

- Genius Bus technology ensures real-time communication with minimal latency (<1 ms), critical for fast-response applications.

-

Reliability and Redundancy:

- Hot-swap capability enables module replacement without system downtime, reducing maintenance costs.

- Dual-controller redundancy support enhances fault tolerance in mission-critical operations.

-

Space-Saving Design:

- Compact form factor minimizes cabinet space requirements, ideal for retrofits or space-constrained installations.

Application Areas and Use Cases

- Manufacturing:

Expands PLC systems in automotive assembly lines to manage robotic arms, conveyor belts, and quality control sensors. - Energy:

Integrates with power plants to monitor turbine sensors and control auxiliary systems across multiple racks. - Water/Wastewater:

Connects distributed I/O racks in treatment plants to monitor pH levels, flow rates, and pump statuses.

Case Study:

A European chemical plant adopted IC697BEM711 modules to expand its aging PLC system. By adding 3 racks with 128 I/O channels, the plant reduced downtime by 22% during batch processing and improved safety by centralizing control of hazardous processes. The module’s redundant design also prevented a $50,000 loss during a controller failure by automatically switching to the backup system.

IC697BEM711

Competitor Comparison

The IC697BEM711 outperforms comparable expansion modules through:

- Rack Density: Supports 4 racks per module, whereas most alternatives limit expansion to 2-3 racks.

- Temperature Range: Operates in extreme conditions (-40°C to 70°C), exceeding standard modules’ 0°C to 50°C range.

- Redundancy Features: Offers dual-controller hot-swap support, a feature often absent in mid-tier expansion solutions.

Selection Recommendations

- System Requirements: Verify your PLC’s compatibility with the Genius Bus protocol and available slots for expansion.

- Scalability Needs: Choose the IC697BEM711 if you require more than 64 I/O channels; GE offers simpler modules (e.g., IC697BEM701) for smaller systems.

- Redundancy Priority: Opt for this module if your application demands fault tolerance, as it eliminates single points of failure.

Precautions

-

Installation:

- Ensure proper grounding and cable routing to minimize electromagnetic interference.

- Use only GE-approved cables for Genius Bus connections.

-

Maintenance:

- Regularly clean dust from ventilation slots to prevent overheating.

- Test redundancy failover annually to confirm operational readiness.

-

Safety:

- Power down the system before inserting or removing modules to avoid electrostatic discharge.

- Secure all connections to prevent accidental dislodging during vibration.