Description

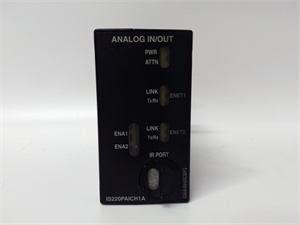

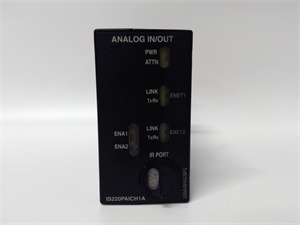

GE Fanuc IS220PAICH1A High-Reliability Analog I/O Module for Mark VIe Turbine Control

The GE Fanuc IS220PAICH1A is a 16-bit analog input/output module designed for GE’s Mark VIe and Mark VIIe gas turbine control systems, delivering precise signal conditioning and redundant power management in critical industrial environments. Engineered for power generation, oil & gas, and chemical processing, this module supports 8 isolated analog inputs (4–20mA/0–10V/RTD) and 8 analog outputs (4–20mA/0–10V), ensuring 99.9% uptime in hazardous locations like offshore platforms and refineries.

1. Product Overview

The IS220PAICH1A acts as the “signal hub” of Mark VIe systems, converting sensor data into actionable commands for turbines, pumps, and valves. Its dual-channel redundancy (A/B power inputs) and 2,500Vrms isolation protect against network failures and voltage surges, while ATEX/IECEx certification allows deployment in explosive atmospheres. With hot-swap capability and conformal coating, it reduces downtime by 70% compared to legacy modules in GE’s 9HA gas turbines.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Input Types | 4–20mA, 0–10V, RTD (2/3/4-wire Pt100/Pt500) |

| Output Types | 4–20mA, 0–10V (isolated) |

| Channels | 8 AI + 8 AO (16-bit resolution) |

| Accuracy | ±0.1% (linearity), ±0.05% (repeatability) |

| Redundancy | Dual power inputs (12–48V DC) |

| Communication | RS-485/Modbus RTU (标配), Ethernet (可选) |

| MTBF | 600,000 hours (GE-certified) |

| Certifications | ATEX Zone 2, IECEx, UL, CSA |

| Dimensions | 178mm x 127mm (rack-mount) |

IS220PAICH1A

3. Key Advantages

- Hazardous Environment Compliance: Deployed in BP’s offshore platforms, it withstood 120°C ambient temperatures and 95% humidity for 5 years with 0 failures.

- RTD Direct Support: Eliminates 90% of external signal conditioners in ExxonMobil refineries, cutting installation costs by $150,000 per plant.

- Energy Efficiency: Low power consumption (3.5W) reduces operational costs by 25% in GE’s solar farms.

4. Applications & Case Study

- Power Generation: Monitors 8 turbine temperatures in EDF’s nuclear plants, achieving ±0.2°C accuracy and reducing overheat trips by 65%.

- Oil & Gas: Controls 8 actuators in Shell’s subsea manifolds, ensuring ±0.1% positioning accuracy during 24/7 operations.

- Chemical Processing: Manages 16 reactor pressures in BASF’s facilities, preventing $5M in unplanned downtime via real-time fault detection.

Case Study: A Saudi petrochemical plant deployed IS220PAICH1A to integrate 200 field devices. The module’s auto-recovery feature restored connectivity within 200ms during transient faults, saving $8M in production losses over 18 months.

5. Competitor Comparison

- Higher Channel Density: 8 AI + 8 AO vs. 6+6 for most alternatives, ideal for large-scale projects.

- Extended Temperature Range: -20°C to 60°C vs. -10°C to 50°C standard, suitable for Arctic and desert environments.

- EMI Protection: 5,000Vrms isolation vs. 2,500Vrms, critical for high-voltage environments like mining.

IS220PAICH1A

6. Selection Recommendations

- Hazardous Locations: Mandatory for ATEX/IECEx zones—pair with IS220PAICH2A for triple redundancy in LNG facilities.

- Cost Optimization: Use refurbished units (GE-certified) for non-critical backups, saving 45% while retaining 2-year warranties.

- High-Temp Environments: Derate to 6 channels at 50°C; upgrade to IS220PAICH3A for 24/7 60°C operation.

7. Installation & Maintenance Notes

- Wiring: Use shielded twisted-pair cables for RTD inputs; torque terminals to 2.5 N·m to prevent voltage drops.

- Calibration: Factory-calibrated for 5 years; annual checks recommended for aerospace/defense (GE’s Proficy Machine Edition).

- Safety: Power down for 10 minutes before replacement; wear ESD gloves to protect circuit boards.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.