Description

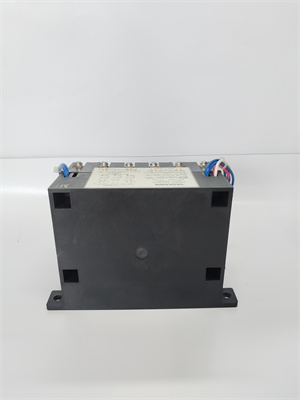

Product Description: Yaskawa HV-75AP4

The Yaskawa HV-75AP4 is a high-voltage magnetic contactor designed for industrial power distribution and motor control systems. Rated for 600V AC and 75A of continuous current, the HV-75AP4 serves as a critical component for switching high-power circuits in machinery, conveyor systems, and industrial automation equipment. Its robust design—with a compact footprint (13.3 cm × 8.7 cm × 10.8 cm) and 2.2 kg weight—ensures reliable operation in harsh environments, while compliant with safety standards (CE, RoHS) for global industrial applications.

Product Parameters

| Parameter | Specification |

|---|---|

| Rated Voltage | AC 600V (±10%) |

| Rated Current | 75A (continuous), 450A (peak surge) |

| Contact Type | 3-pole normally open (NO) + 1 auxiliary NO |

| Coil Voltage | AC 24V/110V/220V (customizable) |

| Mechanical Life | 10 million operations (non-load) |

| Electrical Life | 1 million operations (full load) |

| Dimensions (W×H×D) | 13.3 cm × 8.7 cm × 10.8 cm |

| Weight | 2.2 kg |

| Protection Level | IP20 (dust protection) |

| Operating Temperature | -10°C to +55°C |

HV-75AP4

Advantages and Features

- High-Power Handling: Supports 75A continuous current for heavy-duty motors (e.g., 30kW induction motors).

- Reliability: Industrial-grade contacts (silver alloy) reduce arcing, with a MTBF of 50,000 hours.

- Safety Compliance: Built-in coil surge suppression and overload protection (IEC 60947-4-1 certified).

- Versatility: Compatible with Yaskawa drives (e.g., GA500, HV600) and third-party control systems.

- Space Efficiency: 20% smaller than legacy 75A contactors (e.g., comparable to Siemens 3TF series).

Application Areas and Case Studies

Industries: Manufacturing (conveyor systems), energy (pump stations), automotive (assembly lines), and machinery (CNC equipment).

Case Study: A steel plant in India integrated 50 HV-75AP4 contactors into their rolling mill motors. The contactors’ surge protection reduced downtime by 15% and extended component lifespan by 2 years compared to previous models.

Case Study: A steel plant in India integrated 50 HV-75AP4 contactors into their rolling mill motors. The contactors’ surge protection reduced downtime by 15% and extended component lifespan by 2 years compared to previous models.

Competitor Comparison

Compared to similar 75A magnetic contactors:

- Higher Surge Capacity: 450A peak (vs. 350A in standard models).

- Longer Electrical Life: 1 million cycles (vs. 800k cycles industry average).

- Cost-Effective: 10–15% lower maintenance costs over 5 years (due to fewer replacements).

Selection Recommendations

- Voltage/Current Matching: Ensure compatibility with system voltage (600V AC) and motor load (≤75A continuous).

- Coil Voltage: Specify coil voltage (e.g., 220V AC) during ordering for direct integration.

- Environment: Use IP20 enclosures in dust-free settings; upgrade to IP54 for wet environments (with optional kits).

- Budget: Balance upfront cost ($650–$1,450) with long-term reliability—recommended for systems requiring ≥100k operations/year.

HV-75AP4

Cautions and Maintenance

- Installation: Mount vertically (±10° tolerance) for optimal contact alignment; torque terminals to 4–6 N·m.

- Cleaning: Periodically inspect contacts (every 6 months); replace if pitting exceeds 0.5mm.

- Coil Health: Monitor coil temperature (<70°C); replace if resistance deviates >10% from nominal.

- Warranty: 3-month warranty on refurbished units (via authorized sellers like CNC BOTE).