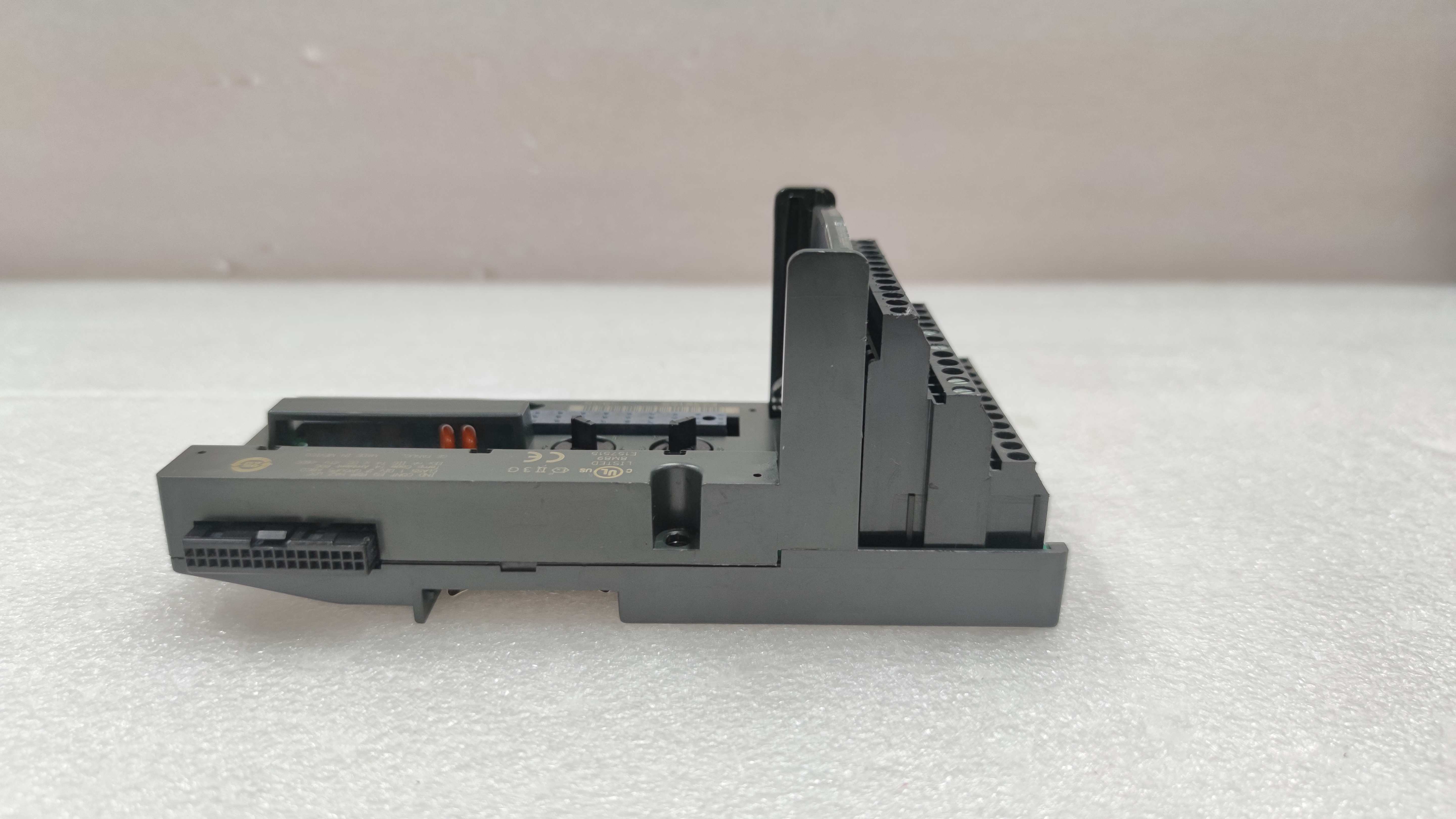

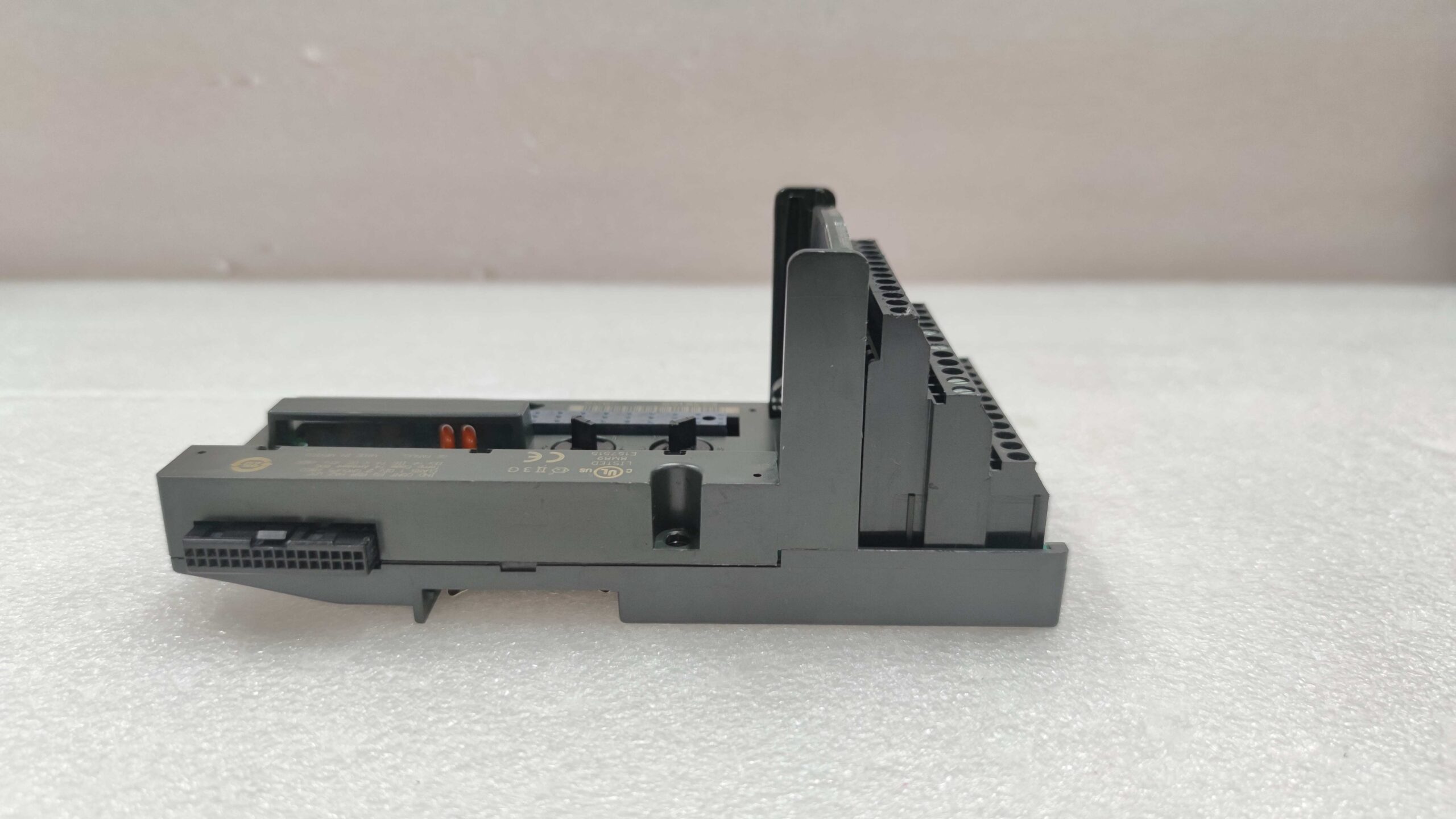

Description

GE Fanuc IC200CHS022 90-30 Series Communication Module

The IC200CHS022 is a highly functional communication module developed by GE Fanuc for its 90-30 series of Programmable Logic Controllers (PLCs). This module plays a crucial role in enabling seamless communication between the PLC and various external devices, systems, and networks. It is designed to meet the demanding requirements of industrial automation environments, providing reliable data transfer and control capabilities.

1. Product Description

The IC200CHS022 serves as a communication gateway for the GE Fanuc 90-30 PLC system. Its core function is to facilitate the exchange of data between the PLC and other devices such as Human-Machine Interfaces (HMIs), sensors, actuators, and other PLCs. By supporting multiple communication protocols, the IC200CHS022 allows for flexible integration with a wide range of equipment. It can handle both serial and network-based communication, making it suitable for different types of industrial setups. One of the key advantages of the IC200CHS022 is its ability to enhance the overall functionality and efficiency of the automation system by enabling real-time monitoring and control.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Communication Ports | RS-232, RS-485 |

| Supported Protocols | Modbus RTU, DF1, others (configurable) |

| Data Transfer Rate (RS-232) | Up to 115200 bps |

| Data Transfer Rate (RS-485) | Up to 1 Mbps |

| Input Voltage | 24V DC ±10% |

| Current Consumption | Approximately 150 mA |

| Compatibility | GE Fanuc 90-30 series PLC racks |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

IC200CHS022

3. Advantages and Features

- High Compatibility: The IC200CHS022 supports multiple communication protocols, which allows it to work with a wide variety of devices from different manufacturers. In a large automotive manufacturing plant, it was able to connect the GE Fanuc PLC with HMIs from another brand and sensors from various suppliers, ensuring seamless communication and integration of the entire production line.

- Reliable Communication: With its robust design and built-in error correction mechanisms, the IC200CHS022 provides reliable data transfer even in harsh industrial environments. In a steel mill, where there is significant electromagnetic interference, the module maintained stable communication, reducing the number of communication errors by 80% compared to previous solutions.

- Flexible Configuration: The module can be easily configured to meet the specific communication requirements of different applications. Engineers can adjust parameters such as baud rate, parity, and data format through the PLC programming software. This flexibility was demonstrated in a food processing plant, where the IC200CHS022 was quickly reconfigured to adapt to changes in the production process.

4. Application Areas and Application Cases

- Manufacturing Industry: In manufacturing plants, the IC200CHS022 is used to connect PLCs with various production equipment, such as robotic arms, conveyor belts, and packaging machines. For example, in an electronics manufacturing plant, it enabled real-time communication between the PLC controlling the assembly line and the quality control sensors, ensuring that only products meeting the required standards moved forward in the production process.

- Energy Sector: In power generation and distribution systems, the IC200CHS022 is used to monitor and control various components. In a wind farm, it connected the PLCs in the turbines with the central control system, allowing for remote monitoring of turbine performance and adjustment of operating parameters as needed.

- Water and Wastewater Treatment: In water treatment plants, the IC200CHS022 is used to connect the PLCs controlling the treatment processes with sensors measuring water quality parameters. In a municipal water treatment plant, it enabled the PLC to receive real-time data from sensors and adjust the chemical dosing and filtration processes accordingly, ensuring the production of clean water.

5. Competitor Comparison

Compared to other similar communication modules in the market, the IC200CHS022 offers several advantages. It has a wider range of supported communication protocols, which means it can integrate with a greater variety of devices without the need for additional adapters. Its data transfer rates are also relatively high, allowing for faster communication and more efficient data exchange. Additionally, its robust design and reliable performance make it more suitable for harsh industrial environments, reducing the likelihood of communication failures and the associated downtime.

IC200CHS022

6. Selection Recommendations

- Compatibility: When selecting the IC200CHS022, ensure that it is compatible with your existing GE Fanuc 90-30 PLC system. Check the communication requirements of the devices you plan to connect to the PLC to ensure that the module supports the necessary protocols.

- Installation Environment: Consider the operating temperature and other environmental factors of the installation location. If the environment is likely to be harsh, such as in a factory with high temperatures or electromagnetic interference, ensure that the module can operate reliably in such conditions.

- Budget: While the IC200CHS022 offers excellent performance and features, also consider your budget. Compare the cost of the module with other similar products in the market, but also take into account the long-term benefits such as reliability and compatibility.

7. Precautions

- Installation: Follow the manufacturer’s instructions carefully when installing the IC200CHS022. Ensure that the power supply is within the specified range and that the communication cables are properly connected.

- Maintenance: Regularly check the module for any signs of damage or malfunction. Clean the module to remove dust and debris, which can affect its performance. Update the firmware of the module as recommended by the manufacturer to ensure optimal performance.

- Safety: When working with the IC200CHS022, follow all safety regulations and procedures. Disconnect the power supply before performing any maintenance or repair work on the module.