Description

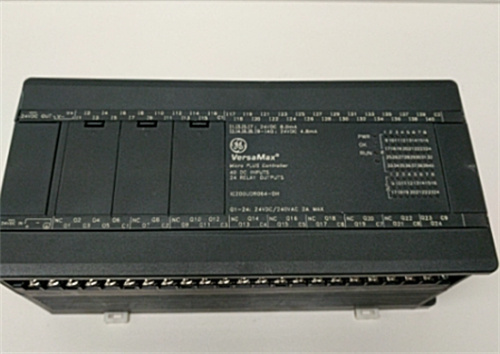

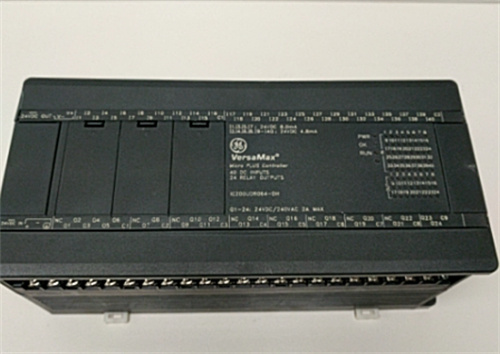

GE Fanuc IC200UDR064 VersaMax Micro 64-Point PLC

1. Product Description

The GE Fanuc IC200UDR064 is a compact, high-performance programmable logic controller (PLC) designed for industrial automation and control systems. Part of the VersaMax Micro family, the IC200UDR064 features 40 digital inputs (24V DC) and 24 relay outputs, making it ideal for applications requiring robust switching of inductive or resistive loads. With a 24V DC power supply and RJ-45 communication interface (支持 Modbus RTU/ASCII), the module integrates seamlessly with GE’s VersaMax expandable systems, offering real-time monitoring, data logging, and remote diagnostics. Its DIN-rail mountable design and Class I Div 2 certification (for hazardous environments) ensure reliability in harsh industrial settings. The IC200UDR064 supports ladder logic programming via GE’s Proficy Machine Edition software, enabling flexible control for small to medium-sized applications.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Input Type | 40 × 24V DC (sinking/sourcing) |

| Output Type | 24 × Relay (2A/250V AC, 2A/30V DC) |

| Power Supply | 24V DC (±15%), 8.0mA (standby), 4.8mA (run) |

| Communication | RJ-45 (Modbus RTU/ASCII, VersaMax Bus) |

| Memory | 16KB user program, 8KB data |

| Expansion | Supports up to 7 VersaMax I/O modules |

| Operating Temperature | -20°C to +60°C (–4°F to 140°F) |

| Storage Temperature | -40°C to +85°C (–40°F to 185°F) |

| Dimensions | 4.6 × 3.9 × 3.1 in (117 × 99 × 79 mm) |

| Weight | 14.5 oz (410 g) |

| Certifications | Class I Div 2 Groups A/B/C/D, CE, UL |

IC200UDR064

3. Advantages and Features

- Relay Output Flexibility: 2A relay outputs handle high-current loads (e.g., motors, valves) without external relays.

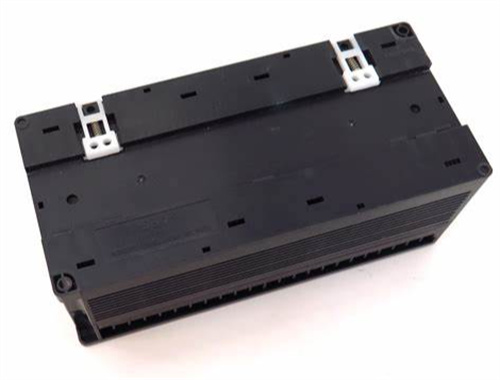

- Compact Design: Space-saving DIN-rail mount (4.6 in width) for crowded control panels.

- Hazardous Environment Compliance: Class I Div 2 certification for use in explosive gas/dust environments.

- Easy Integration: Plug-and-play with VersaMax I/O modules (e.g., analog, temperature, communication).

- Reliable Power Management: Wide voltage tolerance (24V DC ±15%) and low power consumption.

- User-Friendly Programming: Intuitive ladder logic via Proficy Machine Edition; no specialized hardware required.

4. Application Fields and Use Cases

Industries: Manufacturing, water/wastewater treatment, energy, material handling.

Scenarios: Pump control, conveyor systems, machine tool automation, lighting management.

Case Study: A food processing plant deployed IC200UDR064 to control 20 conveyor lines and 15 packaging machines. The relay outputs reliably switched 24V DC solenoids and 120V AC motors, while Modbus integration with a SCADA system reduced downtime by 25% through predictive maintenance.

Scenarios: Pump control, conveyor systems, machine tool automation, lighting management.

Case Study: A food processing plant deployed IC200UDR064 to control 20 conveyor lines and 15 packaging machines. The relay outputs reliably switched 24V DC solenoids and 120V AC motors, while Modbus integration with a SCADA system reduced downtime by 25% through predictive maintenance.

5. Competitor Comparison

Compared to similar compact PLCs:

- Higher Output Current: 2A relay outputs (vs. 0.5–1A in standard models).

- Hazardous Environment Rating: Class I Div 2 certification (many alternatives lack this).

- Expansion Capability: Supports 7 I/O modules (vs. 3–5 in competitive units).

- Power Efficiency: Lower standby current (8.0mA) for energy-saving operations.

IC200UDR064

6. Selection Recommendations

- I/O Requirements: Choose the IC200UDR064 for ≥24 relay outputs; opt for DC transistor outputs (e.g., IC200UDD064) for high-speed switching.

- Environment: Ensure temperature (-20°C to +60°C) and humidity (5–95% non-condensing) match site conditions.

- Load Type: Use relay outputs for inductive/resistive loads; select transistor outputs for PWM or high-frequency signals.

- Expansion Needs: Pair with VersaMax modules (e.g., IC200ALG230 analog input) for complex control systems.

7. Precautions

-

Wiring Safety: Use twisted shielded cables for input signals; observe polarity for DC inputs.

-

Relay Life Cycle: Rated for 100,000 operations (resistive loads); derate for inductive loads (e.g., motors).

-

Power Stability: Maintain clean 24V DC supply (voltage spikes >30V may damage the module).

-

Heat Management: Ensure adequate ventilation; avoid stacking modules in enclosed cabinets.

-

Program Backup: Regularly save ladder logic programs to prevent data loss.