Description

1. Product Description

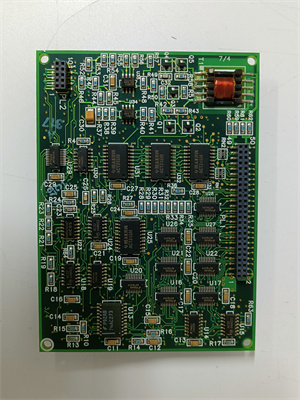

The GE Fanuc IC660ELB912 is a high-performance μGENI Network Interface Board designed for industrial automation systems, part of the Genius I/O product family. Engineered as a daughterboard for microprocessor systems, the IC660ELB912 enables seamless communication between host controllers (e.g., IBM PC/AT/XT) and the Genius I/O bus, supporting remote I/O control and data exchange. It handles all data transfers, freeing the host to manage critical tasks while leveraging the Genius I/O’s reliability and noise immunity. With support for up to 30 bus devices and configurable baud rates (38.4K, 76.8K, 153.6K standard/extended), the module maintains real-time data images of connected devices and facilitates communication via global data, datagrams, and directed control messages. Its dual-port RAM architecture ensures efficient data sharing between the 6303 microprocessor (message handling) and 64180 manager microprocessor (system control). The IC660ELB912 is ideal for distributed control systems in manufacturing, energy, and process industries, offering robust connectivity and diagnostic capabilities.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Type | μGENI Network Interface Board (Daughterboard) |

| Compatibility | IBM PC Interface Module (PCIM: single-slot IC660ELB921 or dual-slot IC660ELB922) |

| Communication Protocol | Genius I/O Protocol |

| Baud Rates | 38.4K, 76.8K, 153.6K (standard/extended) |

| Supported Devices | Up to 30 per daughterboard |

| Memory | 16 KB shared RAM (32 KB for dual boards) |

| Power Requirement | 5V DC, 400 mA (logic power) |

| Current Consumption | 1.0 A (single-slot PCIM); 1.5 A (dual-slot PCIM with 2 boards) |

| LED Indicators | GENI OK (operation status), COMMS OK (communication status) |

| Operating Temperature | 0–60°C (32–140°F) |

| Storage Temperature | -40–70°C (-40–158°F) |

| Humidity | 5–95% (non-condensing) |

| Mounting | DIN rail/PCB with spacers (4 corner holes) |

IC660ELB912

3. Advantages and Features

- High Device Density: Supports up to 30 bus devices per board, ideal for large-scale distributed systems.

- Flexible Communication: Configurable baud rates and dual-port RAM enable efficient data exchange across Genius I/O networks.

- Diagnostic Visibility: LED indicators (GENI OK, COMMS OK) provide real-time status monitoring.

- Space-Saving Design: Compact daughterboard form factor with minimal airflow requirements (1/8-inch clearance from other components).

- Reliability: Built-in fault management and noise immunity (Genius I/O bus features) reduce downtime.

- Compatibility: Optimized for IBM PC buses but adaptable to other CPU types via shared RAM.

4. Application Areas and Use Cases

Industries: Manufacturing, energy, water treatment, and automotive production.

Scenarios: Remote I/O control, machine-to-machine communication, and industrial network management.

Scenarios: Remote I/O control, machine-to-machine communication, and industrial network management.

Case Study: A manufacturing plant integrated the IC660ELB912 with a dual-slot PCIM to manage 28 remote I/O devices across a factory floor. The module’s 153.6K baud rate and fault management reduced communication latency by 20%, improving production line synchronization and enabling predictive maintenance through real-time data monitoring.

5. Competitive Comparison

Compared to similar network interface modules:

- Higher Device Support: 30 devices (versus typical 15–20 in 竞品).

- Dual-Port RAM Architecture: Enables concurrent data access by two processors (unique in its class).

- Baud Rate Flexibility: Supports extended 153.6K baud for high-speed applications.

- Cost-Effective Scalability: Single/double-slot configurations reduce hardware costs in multi-network setups.

IC660ELB912

6. Selection Recommendations

- Compatibility: Ensure compatibility with your PCIM (single/double-slot) and host CPU (e.g., IBM PC/AT/XT).

- Device Count: Match the number of remote I/O devices (up to 30 per board).

- Baud Rate: Choose baud rate based on network distance and data volume (higher rates for shorter distances).

- Power Budget: Account for current consumption (1.0–1.5 A) in system power design.

- Space Constraints: Verify mounting space (1/8-inch clearance) and airflow requirements.

7. Precautions

- Installation: Use spacers/screws for secure mounting; avoid adhesive products. Maintain 1/8-inch clearance for airflow.

- Power Stability: Use a stable 5V DC supply to prevent logic errors.

- Configuration: Set DIP switches for baud rate and device addressing per the manual.

- Redundancy: Deploy dual boards in critical systems for fault tolerance.

- Firmware Updates: Regularly update firmware via GE Fanuc/Emerson tools for compatibility and security.