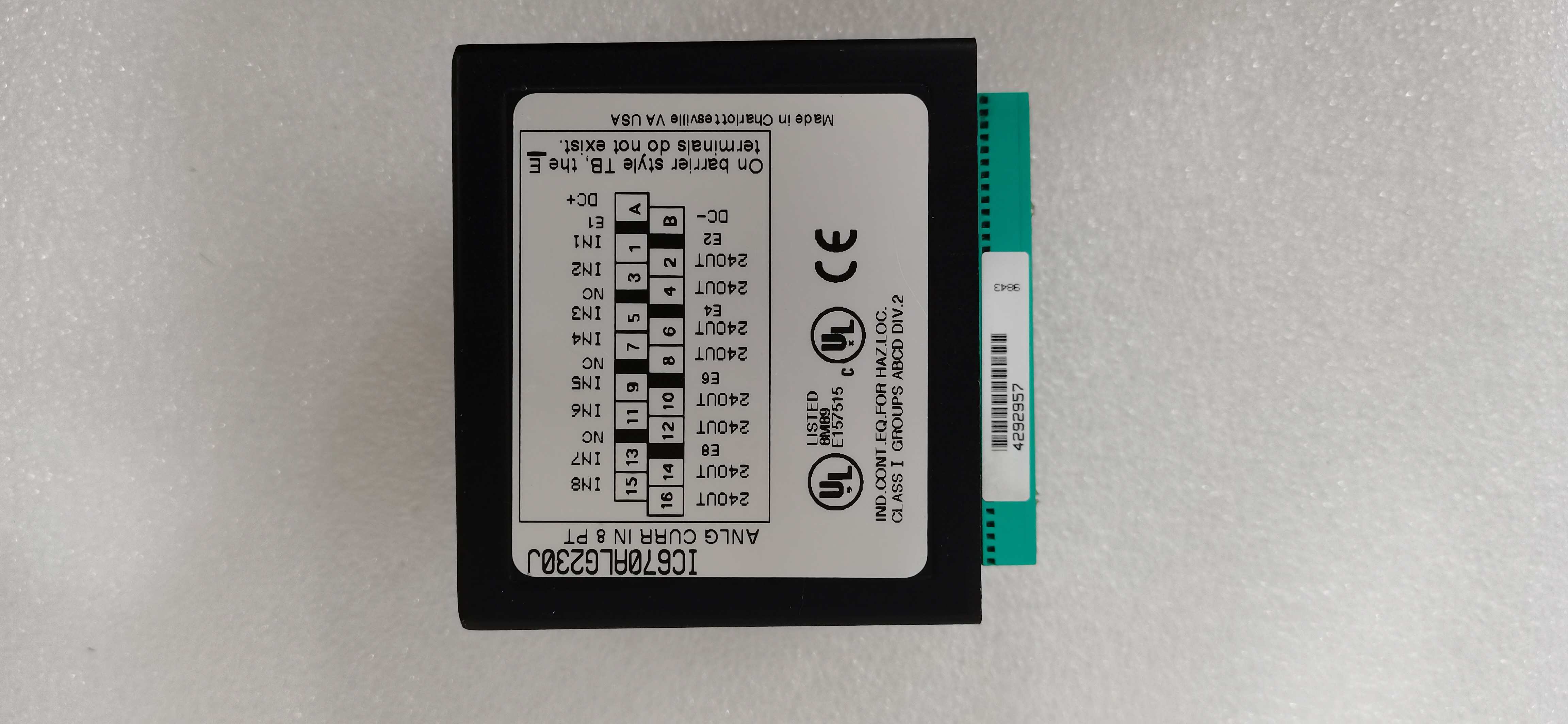

Description

1. Product Description

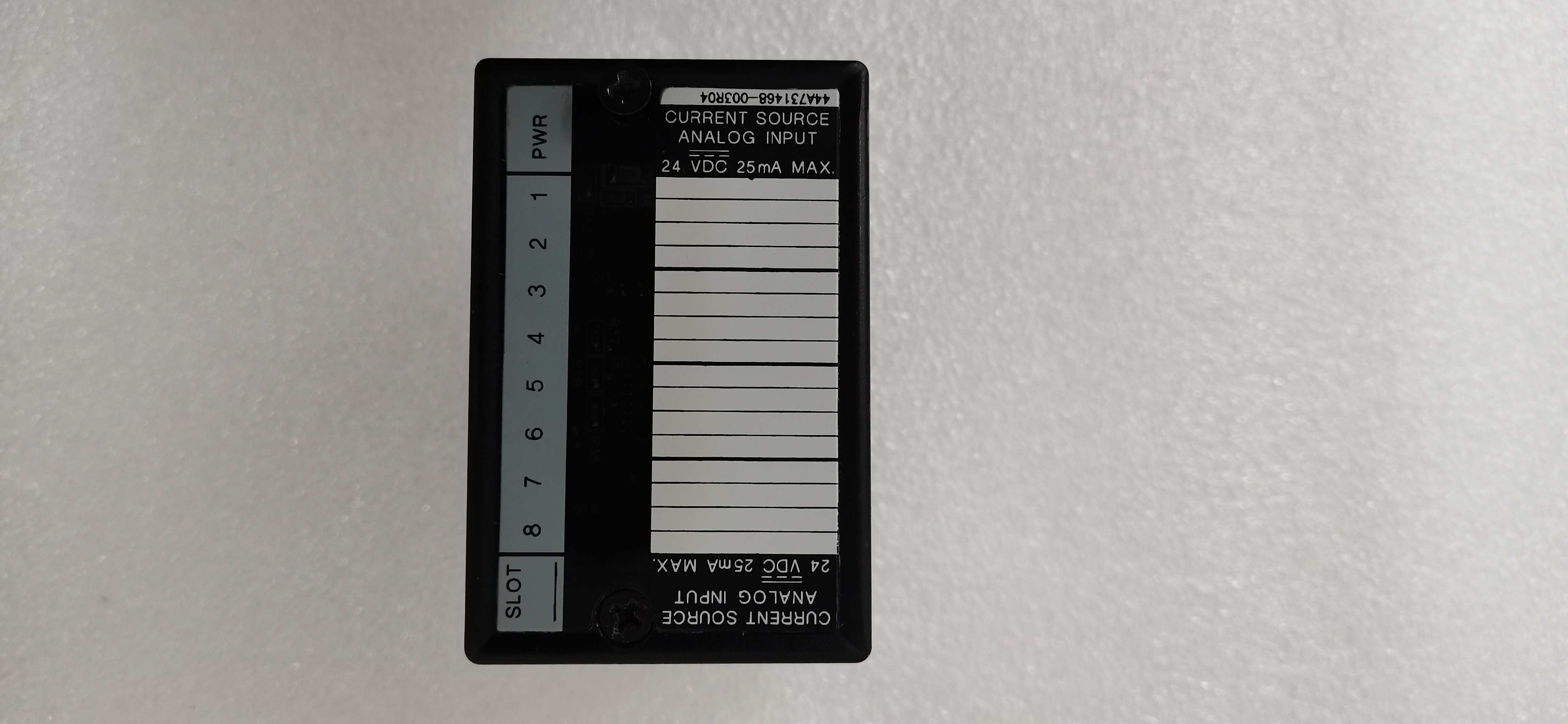

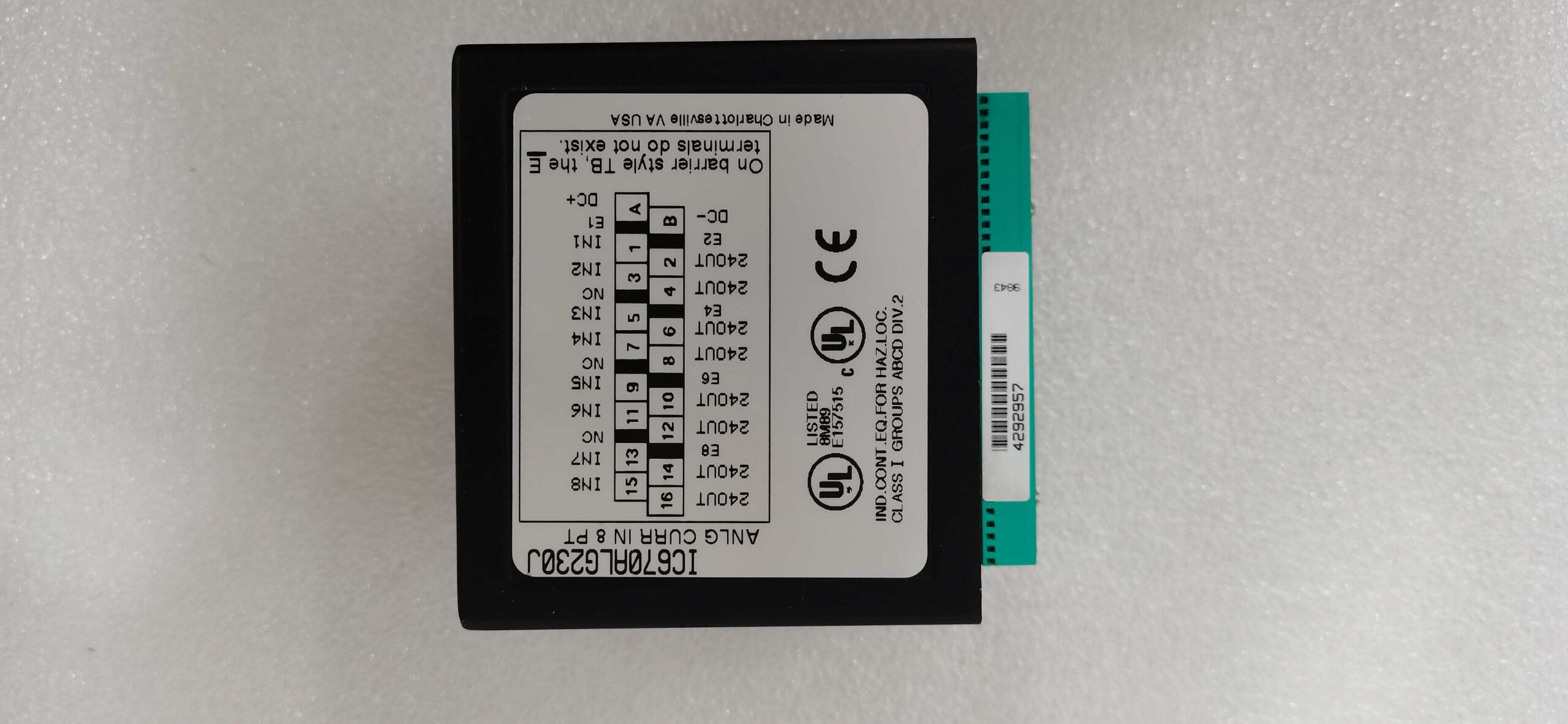

The IC670ALG230 is a high-performance analog input module designed by GE Fanuc for its PACSystems RX3i platform. Engineered for industrial automation and process control, the IC670ALG230 supports 16-channel analog input (4–20mA, ±10V) with 16-bit resolution and advanced signal conditioning. It features galvanic isolation (2.5kVrms), built-in cold-junction compensation for thermocouples, and configurable alarm thresholds. The module integrates with GE’s Proficy software for seamless system integration, enabling real-time monitoring in harsh environments (e.g., temperature ranges of -40°C to 70°C). Ideal for applications requiring precise data acquisition, the IC670ALG230 ensures reliable operation in power generation, manufacturing, and water treatment systems.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Type | 4–20mA, ±10V, thermocouples (J, K, T, E, R, S, B, N), RTD (Pt100, Pt200, Pt500) |

| Channels | 16 (differential or single-ended) |

| Resolution | 16-bit (±0.015% FSR accuracy) |

| Voltage Range | ±10V (±15V overvoltage protection) |

| Current Range | 4–20mA (30mA max) |

| Isolation | 2.5kVrms (channel-to-chassis/ground) |

| Update Rate | 10ms (per channel) |

| Configuration | Software-configurable via Proficy Machine Edition (ME) |

| Compatibility | GE PACSystems RX3i (IC670 series backplane), I/O buses (PCI Express, Ethernet) |

IC670ALG230

3. Advantages and Features

- High Precision: 16-bit resolution with ±0.015% accuracy for critical process measurements.

- Versatile Inputs: Supports thermocouples, RTDs, and analog signals without additional modules.

- Rugged Design: Industrial-grade components (coated PCBs, wide temperature range) for 10+ years of service.

- Smart Diagnostics: Real-time channel status (open circuit, overrange), self-test (POST), and fault logging.

- Modular Flexibility: Hot-swap capability and scalable I/O (expandable via RX3i backplane).

4. Application Areas and Use Cases

Industries: Power generation (gas/steam turbines), oil & gas, water/wastewater, manufacturing.

Applications: Temperature/pressure monitoring, process control loops, machine health diagnostics.

Case Study: A chemical plant in Texas upgraded to the IC670ALG230 for its reactor monitoring system, achieving 99.9% uptime through accurate thermocouple measurements and rapid fault detection (reducing calibration cycles by 40%).

Applications: Temperature/pressure monitoring, process control loops, machine health diagnostics.

Case Study: A chemical plant in Texas upgraded to the IC670ALG230 for its reactor monitoring system, achieving 99.9% uptime through accurate thermocouple measurements and rapid fault detection (reducing calibration cycles by 40%).

5. Competitive Comparison

Compared to standard analog input modules:

- Integrated Signal Conditioning: Eliminates need for external transmitters (saves 20–30% in cabling costs).

- Enhanced Isolation: 2.5kVrms protection (industry standard: 1.5kVrms) for noise-sensitive environments.

- Software Native Integration: Predefined tags in GE Proficy ME reduce programming time by 50%.

IC670ALG230

6. Selection Recommendations

- Compatibility: Verify backplane compatibility (RX3i series; avoid legacy VersaMax systems).

- Environment: Match temperature (-40°C to 70°C) and vibration (5–500Hz, 5g) requirements.

- Scalability: Pair with IC670CPUE050 for distributed control in large-scale systems.

7. Precautions

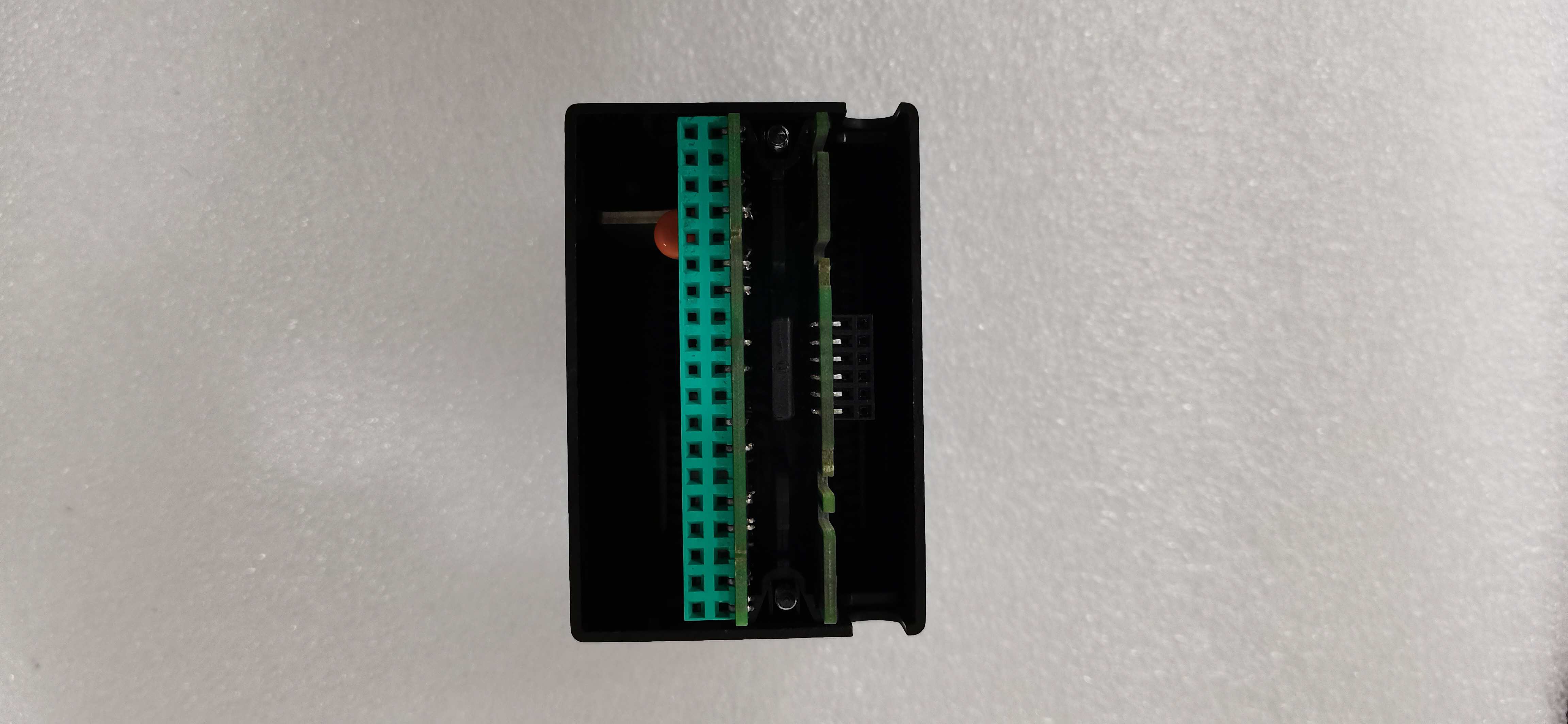

- Installation: Follow GE’s wiring guidelines (separate analog/digital cabling; shielded twisted pairs for thermocouples).

- Calibration: Factory-calibrated (traceable to NIST); recheck every 2 years in high-precision applications.

- Safety: Disconnect power before module replacement; use ESD protection (ESD rating: ±8kV air discharge).