Description

1. Product Description

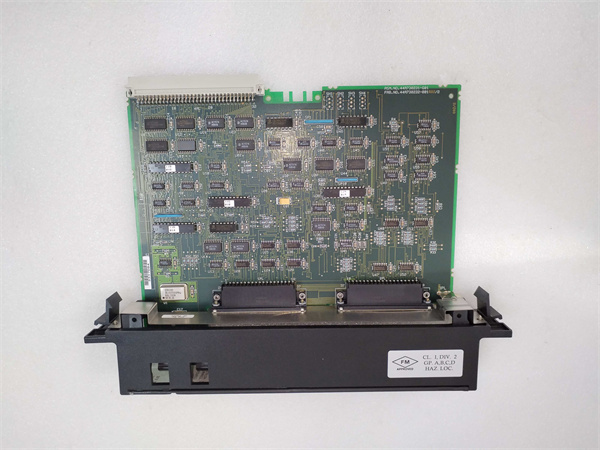

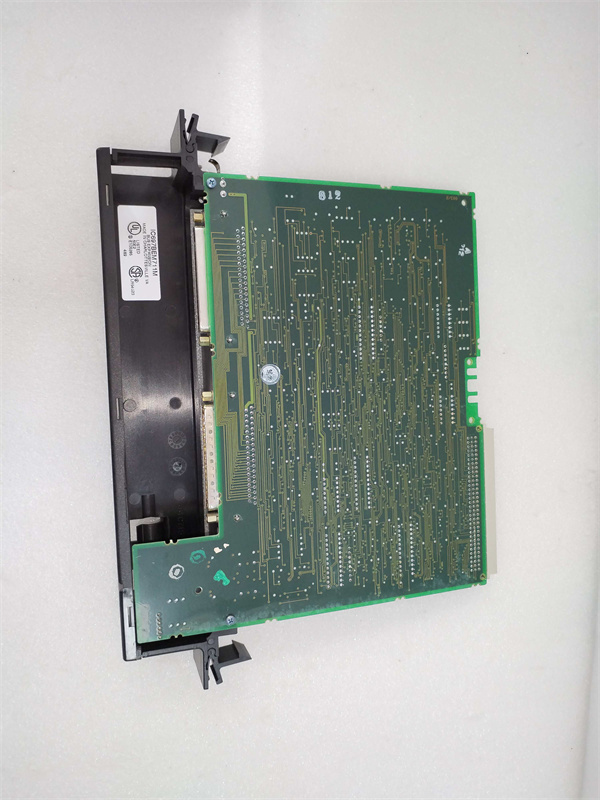

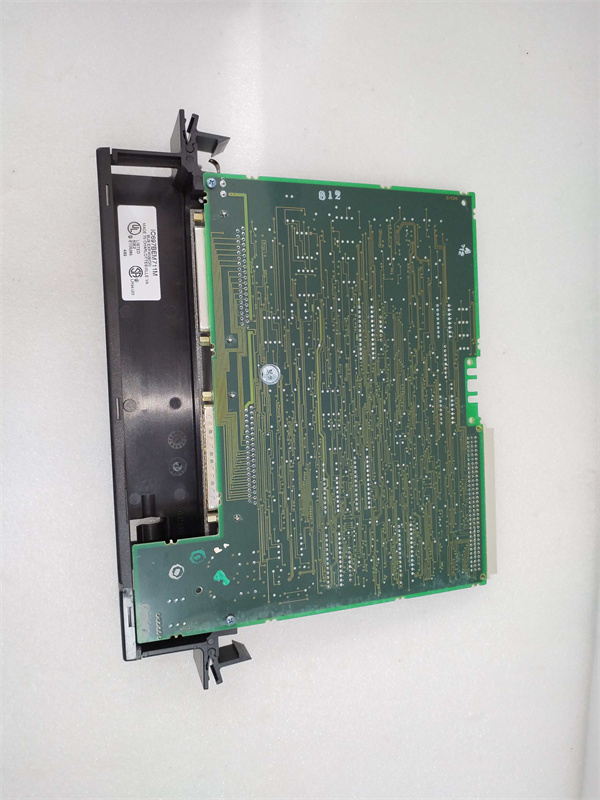

The IC697BEM711 is a high-performance Profibus-DP Master/Slave Communication Module by GE Fanuc (now part of General Electric), designed for the Versamax™ I/O platform. Engineered for industrial automation, this module enables seamless real-time communication (up to 12 Mbps) between PLCs, HMIs, and field devices in manufacturing, energy, and process control systems. The IC697BEM711 supports dual-port redundancy, hot-swap functionality, and Class 1 Div 2 certification for hazardous environments. With compatibility across GE’s Versamax, PACSystems RX3i, and RX7i platforms, it simplifies integration in complex setups. GE’s IC697BEM711 stands out for its compact design (1.5” width), support for up to 125 slaves per network, and advanced diagnostic capabilities, making it ideal for critical applications requiring reliability and scalability.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Module Type | Profibus-DP Master/Slave Communication |

| Voltage | 24 V DC (±10%) |

| Current | 110 mA (operating), 180 mA (max startup) |

| Communication | Profibus-DP V1 (IEC 61158), 9.6 kbps–12 Mbps |

| Nodes Supported | Up to 125 slaves (Master); 1 Master (Slave) |

| Redundancy | Dual-port (A/B) for network redundancy |

| Temperature Range | -40–70 °C (operating), -40–85 °C (storage) |

| Mounting | DIN rail (35 mm) |

| Dimensions | 1.5” (W) × 4.5” (H) × 3.2” (D) |

| Certifications | CE, UL 508, Class 1 Div 2 (hazardous locations) |

| LED Indicators | Power, Run, Fault, Bus A/B Activity, Slave Status |

IC697BEM711

3. Advantages and Characteristics

- Dual-Port Redundancy: Ensures 99.99% uptime with automatic failover, reducing network downtime by 50% in redundant setups.

- Hazardous Environment Compliance: Class 1 Div 2 certification for safe operation in oil, gas, and chemical plants.

- Hot-Swap Capability: Module replacement without system shutdown, minimizing maintenance disruptions.

- Compact Design: 1.5” width saves 20% panel space compared to legacy modules.

- Advanced Diagnostics: Real-time fault monitoring and slave status indicators for proactive maintenance.

4. Application Areas and Cases

Industries: Petrochemical, power generation, water treatment, and automotive manufacturing.

Case Study: A German automotive plant integrated the IC697BEM711 into its assembly line control system. The module’s dual-port redundancy and 12 Mbps data rate supported 100+ field devices (sensors, actuators), reducing cycle time by 15% and eliminating unplanned downtime. Its Class 1 Div 2 certification also ensured compliance in paint shop environments with flammable vapors.

Case Study: A German automotive plant integrated the IC697BEM711 into its assembly line control system. The module’s dual-port redundancy and 12 Mbps data rate supported 100+ field devices (sensors, actuators), reducing cycle time by 15% and eliminating unplanned downtime. Its Class 1 Div 2 certification also ensured compliance in paint shop environments with flammable vapors.

5. Competitor Comparison

Compared to similar Profibus modules:

- Extended Temperature Range: Operates at -40–70 °C (vs. -25–60 °C for many alternatives).

- Integrated Redundancy: Built-in dual-port redundancy (no external modules required).

- Faster Data Rates: 12 Mbps (vs. 1–2 Mbps for legacy models).

- Hazardous Location Support: Class 1 Div 2 certification (unique in entry-level Profibus modules).

IC697BEM711

6. Selection Recommendations

- Compatibility: Ensure GE Versamax, RX3i, or RX7i system compatibility; verify Profibus-DP V1 requirements.

- Environment: Prioritize Class 1 Div 2 certification for hazardous locations (e.g., petrochemical, oil/gas).

- Scalability: Ideal for networks with 50–125 slaves (full Profibus-DP addressing support).

- Cost Efficiency: Balance upfront cost with long-term savings (hot-swap reduces maintenance labor costs by 30%).

7. Precautions

-

Installation: Use AWG 22–16 cables for Profibus connections; secure DIN rail mounting.

-

Power Supply: Use a filtered 24 V DC source (±10%) to prevent voltage fluctuations.

-

Network Configuration: Terminate Profibus networks correctly; limit cable length (1,200 meters at 9.6 kbps; 200 meters at 12 Mbps).

-

Safety: Disconnect power before hot-swapping; follow hazardous location wiring standards (e.g., conduit seals for Class 1 Div 2).