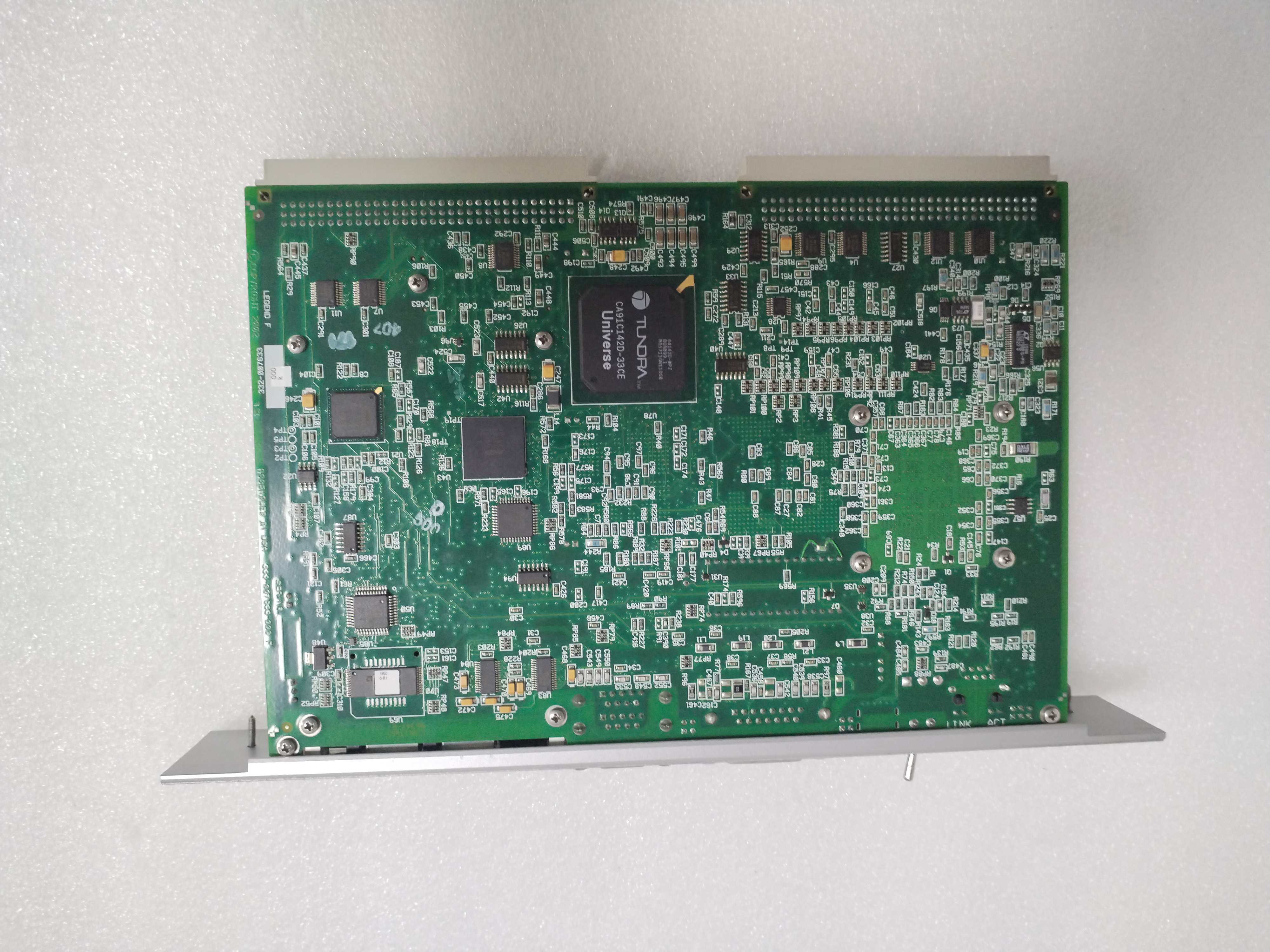

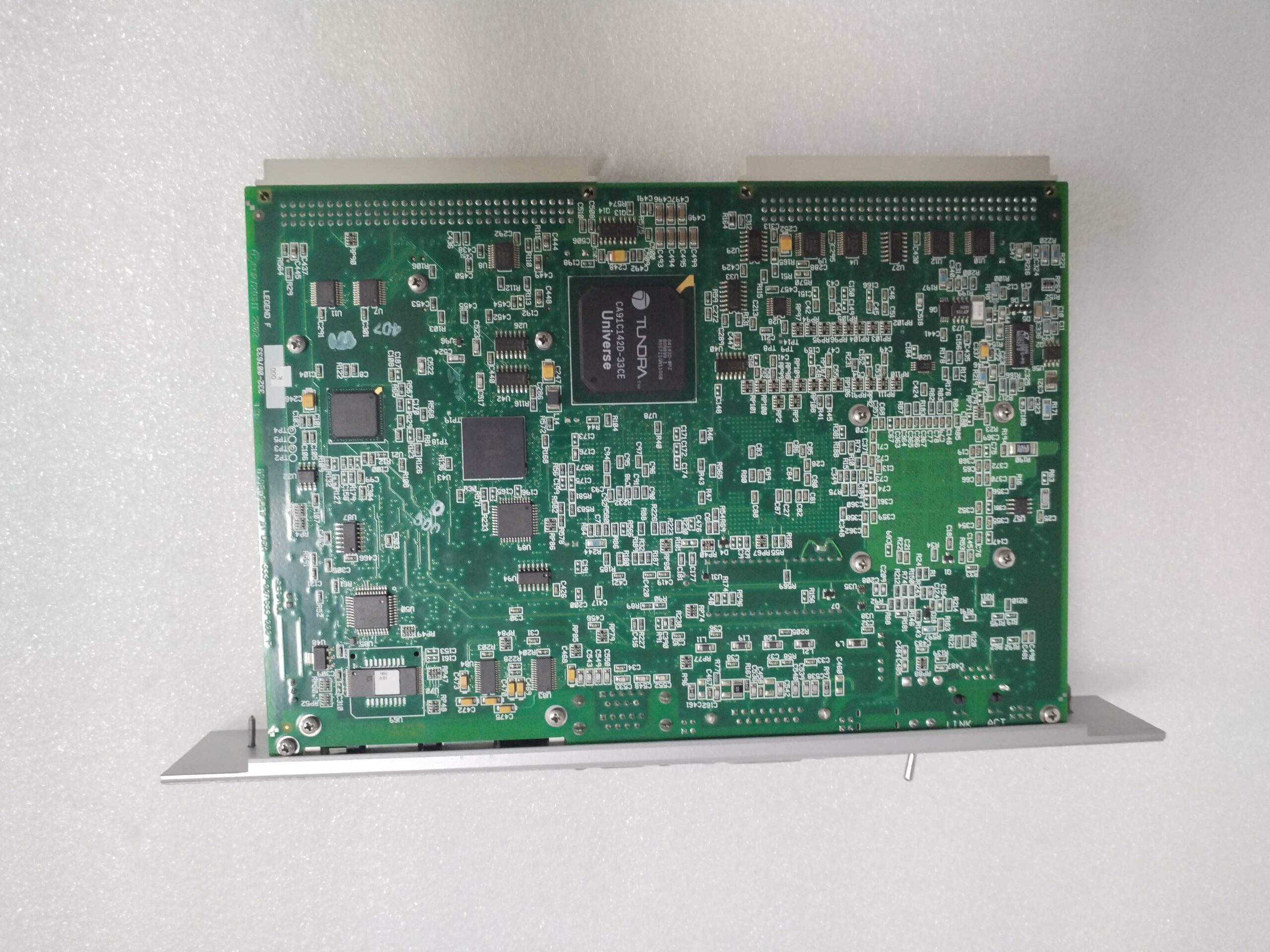

Description

1. Product Description

The GE Fanuc IC698CPE010 is a versatile controller processor module engineered for industrial applications requiring precision and durability. With a 32-bit RISC processor and 512 MB of user memory, the IC698CPE010 handles high-speed logic, motion control, and data acquisition tasks efficiently. Its modular design allows easy expansion via the RX3i backplane, supporting I/O modules, communication cards, and specialty peripherals. Key features include support for Ethernet/IP, Modbus, and Profibus protocols, ensuring compatibility with diverse industrial networks. The IC698CPE010 is built for harsh environments, with wide temperature ranges and shock/vibration resistance, making it suitable for challenging operational conditions.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Processor | 32-bit RISC (400 MHz) |

| Memory | 512 MB user memory, 128 MB system memory |

| Communication Interfaces | Ethernet/IP, RS-232/485, USB 2.0 |

| Voltage | 24 V DC (18–30 V DC input range) |

| Backplane Compatibility | GE Fanuc RX3i series (10-slot backplane) |

| Operating Temperature | -40°C to +70°C (industrial grade) |

| Certifications | CE, UL, CSA, RoHS |

IC698CPE010

3. Advantages and Features

- High Reliability: Rated with a MTBF of 200,000+ hours (per MIL-HDBK-217F), ensuring minimal downtime.

- Real-Time Performance: 400 MHz processor with deterministic execution (cycle times < 1 ms for small programs).

- Scalability: Supports up to 10,000 I/O points via the RX3i backplane, ideal for large-scale systems.

- Energy Efficiency: Low power consumption (≤ 10 W) with sleep mode for reduced energy use.

- Security: Built-in password protection and firmware encryption to safeguard intellectual property.

4. Application Areas and Case Studies

Industries: Manufacturing (assembly lines), energy (power plants), water/wastewater treatment, and automotive.

Case Study: A food processing plant integrated the IC698CPE010 into its packaging line, reducing cycle times by 15% and improving OEE (Overall Equipment Effectiveness) by 12% through real-time machine synchronization and predictive maintenance alerts.

Case Study: A food processing plant integrated the IC698CPE010 into its packaging line, reducing cycle times by 15% and improving OEE (Overall Equipment Effectiveness) by 12% through real-time machine synchronization and predictive maintenance alerts.

5. Competitor Comparison

Compared to similar controllers, the IC698CPE010 offers:

- Superior Compatibility: Native support for 12+ industrial protocols (vs. 8–10 in 竞品).

- Faster Data Throughput: 100 Mbps Ethernet/IP (vs. 50 Mbps in comparable models).

- Longer Lifecycle: Backward compatibility with legacy GE Fanuc systems (10+ years of support).

IC698CPE010

6. Selection Recommendations

- Compatibility: Ensure alignment with existing RX3i backplanes and I/O modules.

- Environment: Verify temperature/pressure ratings match operational conditions (e.g., -40°C for outdoor use).

- Performance Needs: Choose the IC698CPE010 for high-speed control (vs. lower-end models for basic logic).

- Budget: Balance features with cost—competitive pricing for its processing power and expandability.

7. Precautions

- Installation: Follow ESD (electrostatic discharge) protocols; use anti-static wrist straps.

- Cooling: Ensure adequate airflow (ambient temperature ≤ 70°C; avoid enclosed spaces without ventilation).

- Firmware Updates: Regularly update firmware via Proficy Machine Edition (PME) to access new features and security patches.

- Redundancy: For critical systems, pair with redundant power supplies and hot-swap capable backplanes.