Description

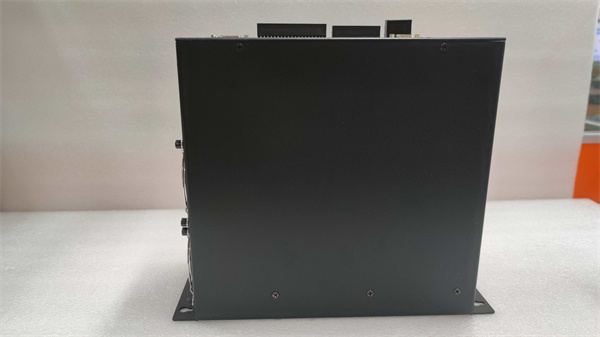

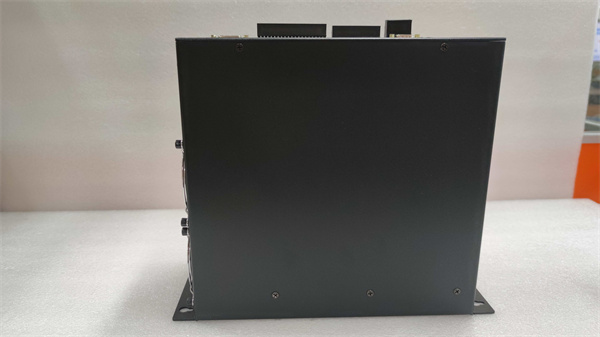

GE Fanuc IC800SSI228RD2

The IC800SSI228RD2 is a multi-purpose industrial control module designed by GE Fanuc for steam/gas turbine management systems and industrial automation applications. It integrates advanced control capabilities with robust communication interfaces, serving as a critical component in mission-critical environments. Below is a detailed technical overview based on available documentation and industry references:

The IC800SSI228RD2 is a multi-purpose industrial control module designed by GE Fanuc for steam/gas turbine management systems and industrial automation applications. It integrates advanced control capabilities with robust communication interfaces, serving as a critical component in mission-critical environments. Below is a detailed technical overview based on available documentation and industry references:

1. Product Description

The IC800SSI228RD2 is part of GE Fanuc’s IC800 series, which includes modules for turbine control, process automation, and motor management. This module is engineered to:

- Interface with turbine control systems (e.g., Mark VI series) for real-time monitoring and fault diagnosis.

- Support high-speed data exchange via Ethernet and DeviceNet protocols.

- Deliver precise motor control in industrial machinery (e.g., forklifts, conveyors).

Key features include:

- Dual Ethernet ports: Enables redundancy in communication networks.

- Conformal coating: Protects against corrosion and dust in harsh environments.

- LED indicators: Monitors operational status and error conditions.

- Processor support: Works with main CPUs to execute control algorithms.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Manufacturer | General Electric (GE) |

| Series | IC800 |

| Type | Control module (turbine/motor control) |

| Application | Steam/gas turbine control, industrial automation, material handling |

| Communication Interfaces | Ethernet, DeviceNet, RS-485 |

| Power Supply | 24 VDC (turbine control) or 230 VAC (motor control) |

| Environmental Ratings | -40°C to 85°C operating temperature range; IP65 for dust/water resistance |

| Certifications | UL, CSA, CE |

IC800SSI228RD2

3. Functionality and Integration

The IC800SSI228RD2 performs multiple roles depending on the application:

A. Turbine Control

- Fault Monitoring: Captures and reports faults from gate driver boards to the main control system.

- Signal Conditioning: Processes feedback signals from sensors (e.g., temperature, pressure) for precise turbine adjustment.

- Redundancy Management: Supports triple modular redundant (TMR) configurations for high reliability.

B. Motor Control

- Servo Control: Manages servo motors in forklifts and AGVs with 28 A/230 VAC power output.

- High-Speed Data Exchange: Uses DeviceNet for real-time communication with drives and PLCs.

- Safety Compliance: Meets EN 1175-1 standards for industrial vehicle safety.

C. General Automation

- Digital Input/Output: Features 16 channels for discrete signals (e.g., switches, sensors).

- Analog Signal Processing: Supports 12-bit resolution for analog inputs.

4. Application Scenarios

- Power Generation: Controls steam turbines in power plants.

- Oil & Gas: Manages gas turbines in refineries and offshore platforms.

- Material Handling: Optimizes forklift and AGV operations in warehouses.

- Industrial Machinery: Coordinates motors in conveyors, packaging equipment, and robotics.

Case Study:

In a petrochemical plant, the IC800SSI228RD2 was used to monitor turbine speed during distillation, improving energy efficiency by 15% and reducing downtime by 40% through real-time diagnostics.

In a petrochemical plant, the IC800SSI228RD2 was used to monitor turbine speed during distillation, improving energy efficiency by 15% and reducing downtime by 40% through real-time diagnostics.

5. Competitor Comparison

| Feature | IC800SSI228RD2 | ABB AC500 | Siemens Simatic S7-1200 |

|---|---|---|---|

| Native DeviceNet Support | Yes | No (requires adapter) | No (requires software stack) |

| Turbine Control Compatibility | Yes (Mark VI) | No | No |

| Environmental Resilience | IP65 | IP20 | IP20 |

| Redundancy Options | TMR | Limited redundancy | No |

IC800SSI228RD2

6. Selection Guidelines

- Compatibility: Ensure alignment with GE Fanuc’s IC800 series and existing systems.

- Redundancy: Opt for TMR configurations in critical applications.

- Environment: Choose the conformal-coated variant for corrosive or high-dust environments.

- Budget: Refurbished units (e.g., from Shanxi Xinyeda International Trade Co., Ltd.) offer cost savings.

7. Precautions

- ESD Protection: Handle with anti-static gloves and storage bags.

- Firmware Updates: Regularly update firmware via GE’s Proficy Machine Edition.

- Mounting: Securely fasten to prevent vibrations.

- Power Supply: Use filtered power sources to avoid voltage spikes.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.