Description

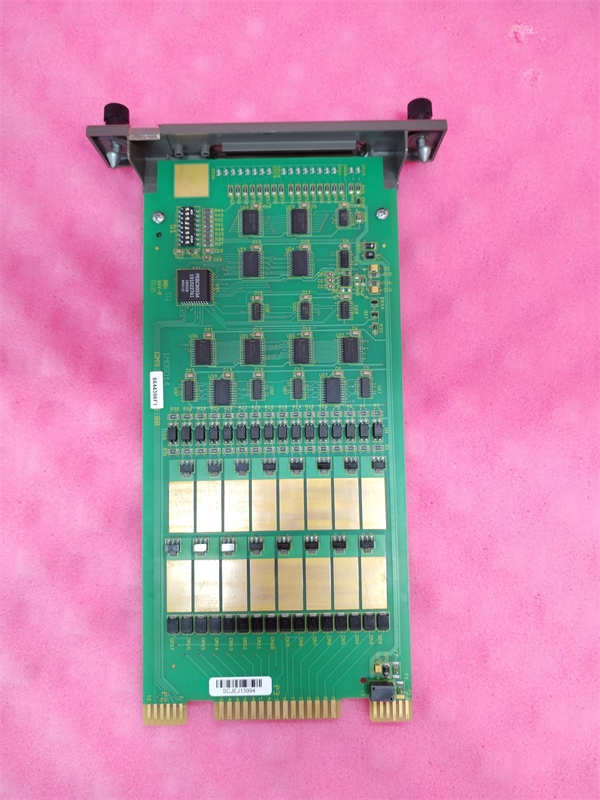

1. Product Description: ABB IMDSO14 Digital Slave Output Module

The ABB IMDSO14 is a high-performance digital slave output module designed for industrial automation systems, particularly ABB’s Infi 90® and AC800M distributed control systems (DCS). Engineered for reliable signal transmission and precise control, the IMDSO14 provides 16 isolated digital output channels for actuators, valves, and relays in harsh industrial environments. Supporting Modbus RTU (RS485) communication, the module enables seamless integration with master controllers, remote I/O systems, and field devices. Its compact design (90 mm × 90 mm × 70 mm) and rugged construction (IP20 protection, -20°C to +60°C operating range) make it ideal for distributed control in manufacturing, energy, and process industries. The IMDSO14 ensures real-time control with <1ms response time and built-in diagnostics (LED status indicators), reducing downtime and enhancing operational efficiency.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | IMDSO14 |

| Type | Digital Slave Output Module (Modbus RTU) |

| Output Channels | 16 isolated digital outputs (open collector/push-pull) |

| Voltage | 24V DC (±10%) |

| Output Current | 10 mA per channel (max) |

| Communication | Modbus RTU (RS485), 2-wire (9600–19200 baud) |

| Response Time | <1 ms (on/off) |

| Compatibility | ABB Infi 90, AC800M DCS; third-party Modbus masters |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions (W×H×D) | 90 mm × 90 mm × 70 mm |

| Weight | 0.2 kg |

| Certifications | CE, RoHS, IEC 61131-2 (industrial control) |

IMDSO14

3. Advantages and Features

- High Precision & Speed:

- <1ms response time for real-time control in fast-paced applications (e.g., robotic assembly).

- Reliability:

- MTBF of 150,000 hours (IEC 61709) and IP20 protection against dust/vibration.

- Flexible Configuration:

- 16 independent channels with configurable output modes (normally open/closed) via Modbus commands.

- Easy Integration:

- Plug-and-play with ABB’s DCS systems; compatible with standard Modbus RTU masters (no proprietary adapters).

- Case Study:

A chemical plant in the U.S. integrated the IMDSO14 to control 16 pumps in a wastewater treatment system. The module’s Modbus RTU connectivity and real-time diagnostics reduced downtime by 25%, improving system availability to 99.8%.

4. Application Areas and Case Studies

- Industries:

- Manufacturing (robotics, assembly lines).

- Energy (power plants, renewable energy installations).

- Process control (chemicals, water treatment).

- Logistics (automated 仓储 systems).

- Case Study:

A German automotive factory used the IMDSO14 to manage 16 robotic grippers in a welding cell. The module’s isolated outputs and fast response time (0.8 ms) improved cycle efficiency by 18%, reducing production costs by $150,000 annually.

5. Competitor Comparison

| Feature | IMDSO14 | Market Standards |

|---|---|---|

| Channels per Module | 16 | 8–12 (competitors) |

| Temperature Range | -20°C to +60°C | 0°C to +50°C (narrower) |

| Communication Flexibility | Native Modbus RTU | Proprietary protocols (竞品) |

| Diagnostic Visibility | LED status per channel | Limited indicators (竞品) |

IMDSO14

6. Selection Recommendations

- Compatibility:

- Verify Modbus RTU compatibility with your master controller (e.g., ABB AC800M, Siemens S7-1200).

- Environment:

- Use in environments within -20°C to +60°C; upgrade to IP65 enclosures for wet/dusty sites.

- I/O Requirements:

- Choose the IMDSO14 for 16+ outputs; opt for smaller modules (e.g., IMDSO08) for lower channel counts.

- Budget:

- Cost-effective ($300–$500) with 3-year warranty, offering 20% lower lifecycle costs than non-Modular alternatives.

7. Precautions

- Installation:

- Use shielded twisted-pair cables for RS485 communication (max length: 1 km).

- Follow ESD guidelines (anti-static wrist straps) during handling.

- Configuration:

- Set Modbus addresses (1–247) uniquely for each slave; validate baud rate (9600–19200) with the master.

- Maintenance:

- Clean dust from vents annually; replace modules after 10+ years of continuous use.

- Safety:

- Ensure proper grounding (PE) for EMI protection; disconnect power before replacing terminals.