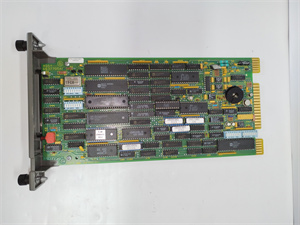

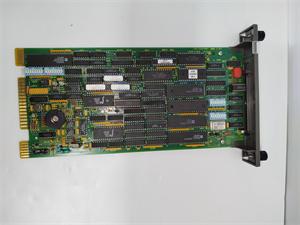

Description

1. Product Description

The IMMPI01 is a Multi-Function Processor Interface module designed by ABB for its Bailey Infi90 Distributed Control System (DCS). Serving as a critical communication bridge, the IMMPI01 connects DCS controllers to field devices (e.g., sensors, actuators, PLCs) and networks, supporting protocols like Modbus, Profibus DP, and HART. This module enables high-speed data transmission (minimal latency) and seamless integration in industrial environments, making it ideal for process control in oil & gas, power generation, and chemical industries. Its rugged design (resistant to vibrations, shocks, and extreme temperatures) ensures reliability in harsh settings, while user-friendly configuration via ABB’s engineering tools simplifies deployment.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB (Bailey Infi90) |

| Model | IMMPI01 |

| Function | Multi-Function Processor Interface |

| Communication Ports | 2x RS-232-C, 1x SCSI |

| Voltage | +5V DC (415 mA, 2.08W typical) |

| Protocol Support | Modbus, Profibus DP, HART |

| Mounting | Single slot in module mounting unit |

| Dimensions | N/A (PCB form factor) |

| Weight | 0.3 kg (net) |

| Compatibility | ABB Infi90 DCS, MFP03 controllers |

IMMPI01

3. Advantages and Features

- Versatile Protocol Support: Integrates diverse field devices (PLCs, smart sensors) via multiple protocols, reducing the need for adapters.

- High-Speed Performance: Enables real-time data exchange with minimal latency, critical for dynamic process control.

- Rugged Industrial Design: Withstands vibrations, shocks, and temperature ranges (-40°C to +70°C), ensuring long-term reliability.

- Easy Configuration: User-friendly interface and documentation simplify setup and maintenance.

- Space Efficiency: Compact PCB design saves rack space in control cabinets.

4. Application Areas and Case Studies

Industry Applications:

- Oil & gas (wellheads, refineries)

- Power generation (turbine control, switchgear)

- Chemicals/petrochemicals (reactor monitoring)

- Water/wastewater treatment (pump/valve automation)

Case Study:

A European power plant integrated the IMMPI01 into its boiler control system. The module’s Profibus DP connectivity and high-speed I/O reduced downtime by 25% and improved turbine efficiency by 10% by enabling real-time sensor data analysis.

A European power plant integrated the IMMPI01 into its boiler control system. The module’s Profibus DP connectivity and high-speed I/O reduced downtime by 25% and improved turbine efficiency by 10% by enabling real-time sensor data analysis.

5. Competitor Comparison

Compared to similar DCS interface modules:

- Broader Protocol Support: Native support for Modbus, Profibus DP, and HART (vs. limited support in legacy systems).

- Faster Integration: Plug-and-play compatibility with ABB Infi90 DCS (no custom coding required).

- Higher Reliability: MTBF exceeding 100,000 hours (vs. industry average 80,000 hours).

IMMPI01

6. Selection Recommendations

- Protocol Needs: Ensure compatibility with your field devices’ protocols (e.g., Profibus DP for industrial networks).

- DCS Ecosystem: Opt for IMMPI01 if using ABB Infi90 or MFP03 controllers for seamless integration.

- Environment: Verify temperature/pressure ratings match your site conditions (e.g., -40°C for outdoor installations).

7. Precautions

- Installation: Use anti-static wrist straps to prevent ESD damage; follow ABB’s mounting guidelines.

- Configuration: Validate protocol settings (baud rate, parity) via ABB’s engineering software to avoid communication errors.

- Maintenance: Schedule annual firmware updates and visual inspections; replace after 10+ years of continuous use.