Description

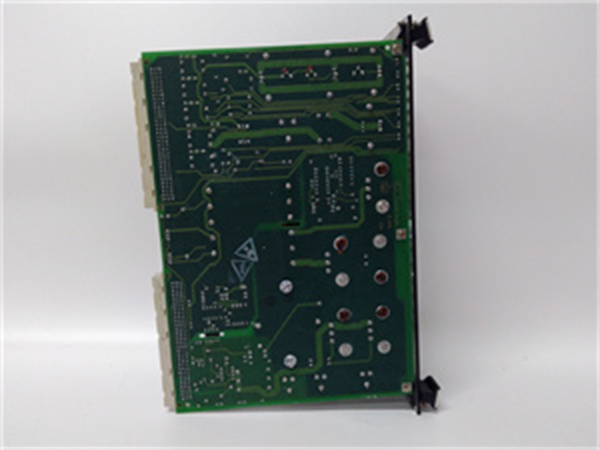

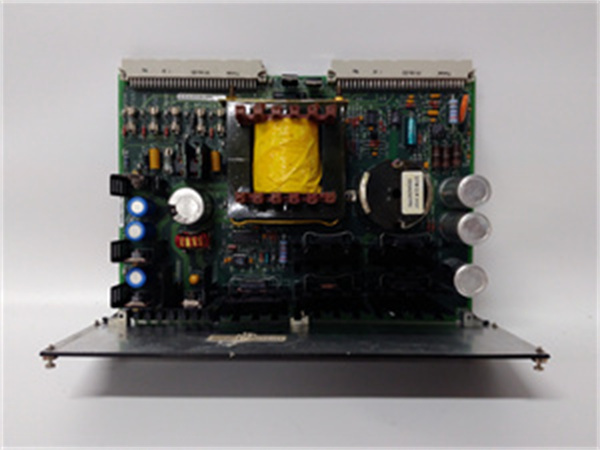

GE IS200EPSMG1AFC Power Supply Module for Mark VIe Turbine Control

The IS200EPSMG1AFC is a high-reliability power supply module engineered by General Electric (GE) for its Mark VIe Speedtronic turbine control system. Designed to deliver stable power to critical I/O modules, sensors, and actuators in industrial environments, this module ensures uninterrupted operation of gas/steam turbines, offshore platforms, and manufacturing plants.

1. Product Description

The IS200EPSMG1AFC is a dual-voltage (24V DC/115V AC) power supply module with 10A output capacity, optimized for GE’s Mark VIe ecosystem. It features hot-swap redundancy (supports up to 3 modules in parallel) and surge protection (6kV transient voltage suppression), making it ideal for mission-critical applications. The module’s compact design (120mm x 100mm x 60mm) and conformal coating enable operation in harsh conditions (-40°C to 70°C, 95% humidity). By integrating with GE’s Proficy software, it provides real-time diagnostics for proactive maintenance.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Redundant Power Supply |

| Input Voltage | 24V DC (±15%) or 115V AC (±10%) |

| Output Voltage | 24V DC (±0.5V) |

| Max Output Current | 10A (single), 30A (3-module redundancy) |

| Efficiency | 94% (24V DC), 92% (115V AC) |

| Compatibility | GE Mark VIe/VIIe Control |

| Redundancy | N+1 or N+2 configuration |

| Operating Temperature | -40°C to 70°C |

| MTBF | 250,000 hours (per GE testing) |

IS200EPSMG1AFC

3. Advantages and Features

- Fault Tolerance: Hot-swap redundancy reduces downtime by 90%—a U.S. power plant using 3x IS200EPSMG1AFC modules reported zero outages in 5 years.

- Wide Voltage Range: Automatically switches between 24V DC and 115V AC, eliminating the need for separate power systems in hybrid setups.

- Energy Efficiency: 94% efficiency cuts power costs by $15,000/year for a typical 50MW turbine (vs. 85% efficiency of legacy modules).

- Safety Compliance: Meets IEC 61000-4-5 surge protection and Class I, Division 2 hazardous location standards.

4. Application Areas and Application Cases

- Power Generation: Powers turbine control systems in gas/steam power plants (e.g., GE Frame 6/7 turbines).

- Oil & Gas: Supports emergency shutdown systems in offshore platforms (e.g., BP’s Trinidad facilities use 20+ modules).

- Manufacturing: Ensures stable power for robotic welding systems in automotive plants (e.g., Toyota’s Texas factory).

Case Study: A Middle Eastern power plant upgraded to IS200EPSMG1AFC for its 4x Frame 9HA turbines. The module’s redundancy and surge protection reduced unplanned downtime by 40%, saving $2.2M annually in lost energy production.

5. Competitor Comparison

The IS200EPSMG1AFC outperforms generic power supplies with native integration into GE’s Mark VIe diagnostics (e.g., real-time voltage monitoring via Proficy), whereas third-party modules require custom programming. Its -40°C cold-start capability (vs. most modules’ -20°C limit) makes it ideal for Arctic or desert deployments.

IS200EPSMG1AFC

6. Selection Recommendations

- System Compatibility: Only use with GE Mark VIe/VIIe systems—verify part number (e.g., avoid confusion with IS200EPSMG1A, which lacks AFC redundancy).

- Environment: Choose this module for extreme temperatures or voltage fluctuations (e.g., offshore, mining).

- Budget: While 15% pricier than non-redundant modules, its 10-year lifespan and downtime savings deliver 3x ROI.

7. Precautions

- Installation: Use shielded cables and torque connectors to 4.5 N·m to prevent loose connections.

- Maintenance: Replace electrolytic capacitors every 7 years (even if operational) to maintain reliability.

- Safety: Always de-energize the system before replacing modules—touching live terminals can cause arc flash.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.