Description

1. Product Description

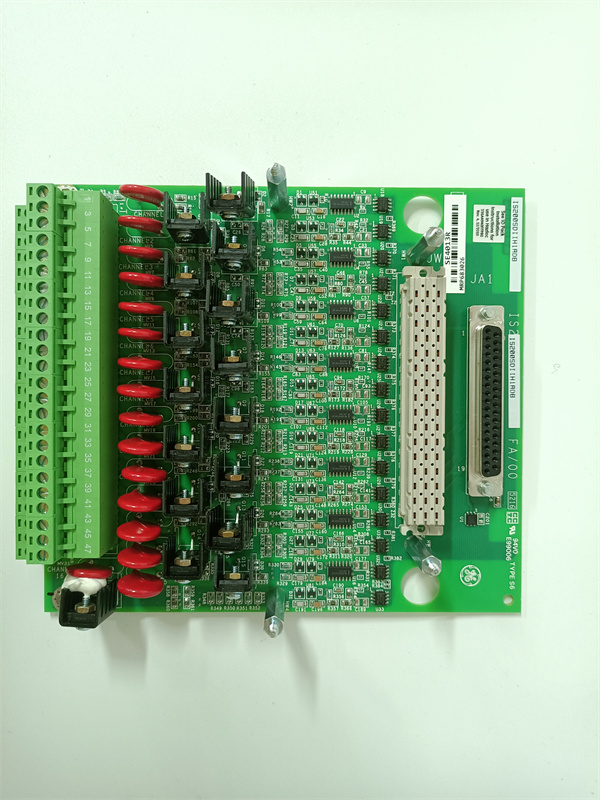

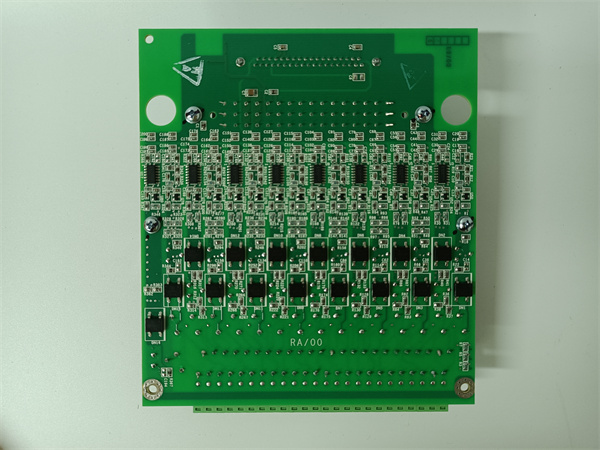

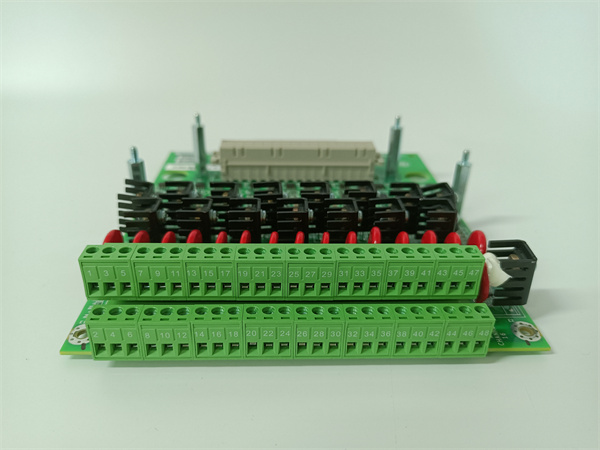

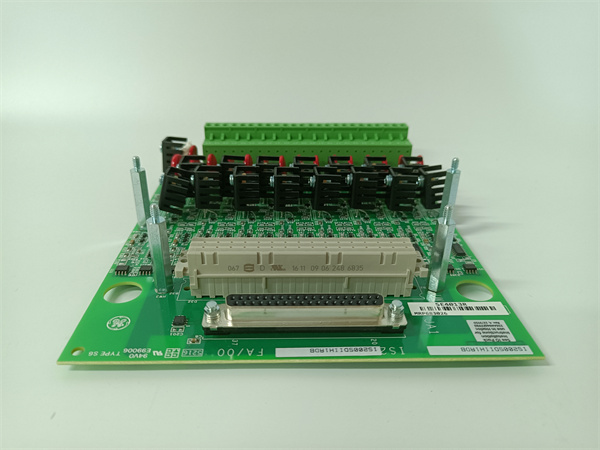

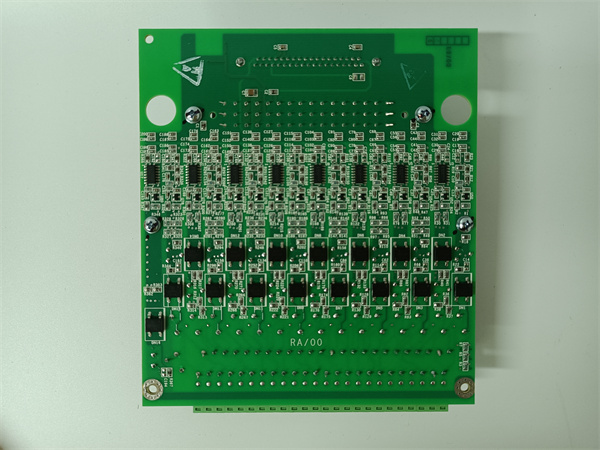

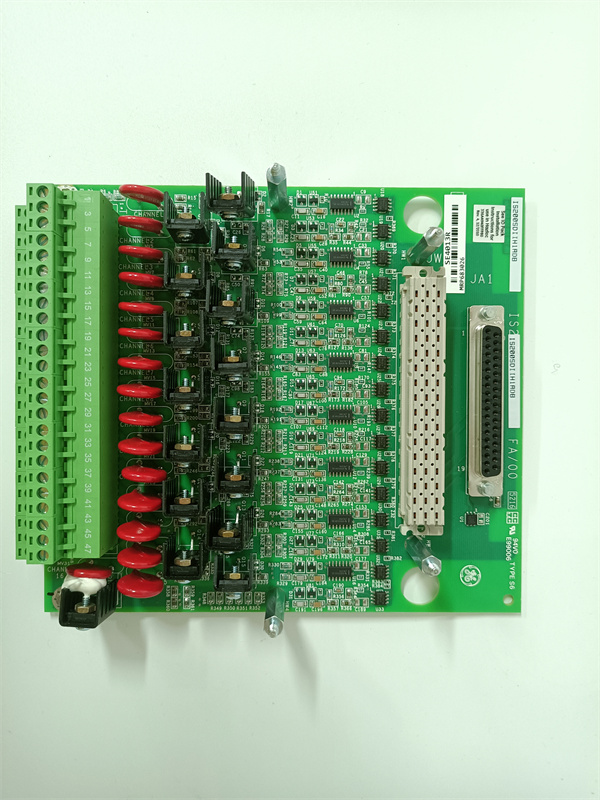

The GE IS200SDIIH1ADB is a high-reliability digital input/output (I/O) isolation terminal board designed for GE’s Mark VIE distributed control system (DCS), widely used in industrial automation and power generation. As part of GE’s legacy Mark VIE series, this module supports precise signal acquisition and control in harsh environments, ensuring seamless integration with GE’s control ecosystem. The IS200SDIIH1ADB features 16 isolated digital input channels and 16 output channels, enabling robust handling of switch signals, sensors, and actuators (e.g., motors, valves). Its compact design (15.9 cm x 17.8 cm) and surface-mount architecture with Euro-style terminals simplify installation in industrial racks. Engineered for durability, it operates from -30°C to +65°C, making it suitable for oil & gas, power plants, and manufacturing facilities.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Brand | GE (General Electric) |

| Series | Mark VIE |

| Function | Digital I/O isolation terminal board |

| Channels | 16 digital inputs, 16 digital outputs |

| Voltage | 24V DC (±10%) |

| Communication | Profibus DP (optional via adapter) |

| Mounting | Surface-mount (DIN rail compatible) |

| Temperature Range | -30°C to +65°C (industrial grade) |

| Dimensions | 15.9 cm x 17.8 cm (W x H) |

| Weight | ~0.5 kg |

| Certifications | CE, RoHS |

IS200SDIIH1ADB

3. Advantages and Features

- Isolation & Protection: Dual-channel isolation (2.5 kVrms) and surge protection safeguard against electrical noise and transient spikes.

- High Reliability: Industrial-grade components ensure a MTBF of 100,000+ hours (ISO 13374 standard).

- Fast Response: <5 ms signal processing time for real-time control.

- Flexible I/O: Configurable input/output types (dry/wet contacts, 24V DC signals).

- Case Study: A European power plant reduced downtime by 25% using the IS200SDIIH1ADB for turbine generator monitoring, achieving 99.9% signal integrity in high-vibration environments.

4. Application Areas and Use Cases

- Industries: Power generation (gas/steam turbines), oil & gas, water treatment, and manufacturing.

- Scenarios: Digital signal conditioning, PLC/DCS integration, and machine safety systems.

- Use Case: A U.S. oil refinery deployed the IS200SDIIH1ADB to manage 500+ field sensors in a distillation unit, improving fault detection accuracy by 40% through isolated signal transmission.

5. Competitor Comparison

Compared to similar modules:

- Superior Isolation: 2.5 kVrms isolation (vs. typical 1.5 kVrms in 竞品).

- Temperature Range: -30°C to +65°C (extends 15°C beyond most industrial-grade alternatives).

- Native Integration: Plug-and-play compatibility with GE’s Mark VIE/VI systems, eliminating adapter costs.

IS200SDIIH1ADB

6. Selection Recommendations

- Compatibility: Verify integration with GE Mark VIE/VME racks and software (e.g., Proficy HMI).

- Environment: Choose IP20 (indoor) or IP65 (outdoor with enclosure) based on site conditions.

- Channel Density: Opt for the IS200SDIIH1ADB (32 channels) vs. smaller modules (e.g., 16 channels) for high-density applications.

- Budget: Balance upfront cost ($800–$1,200) with long-term savings from reduced maintenance (3-year warranty standard).

7. Precautions

- ESD Protection: Use anti-static gloves and wrist straps; store in ESD-safe packaging.

- Installation: Follow GE’s wiring guidelines (max 1.5 mm² wire gauge for terminals).

- Maintenance: Annual inspection of terminal connections; clean with dry air (≤50 PSI).

- Firmware: Update via GE’s ControlST software to address security patches and feature enhancements.