Description

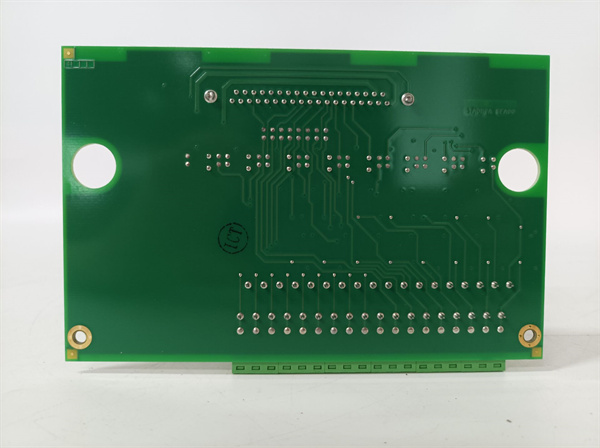

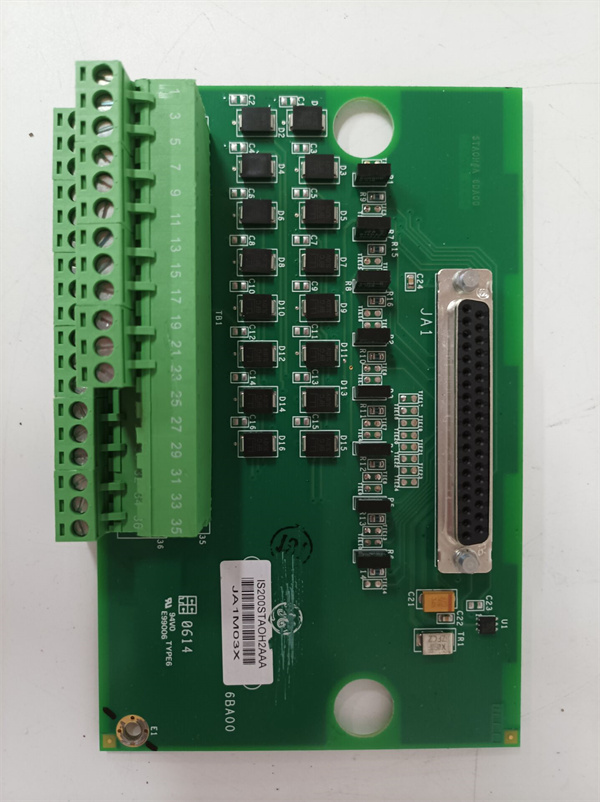

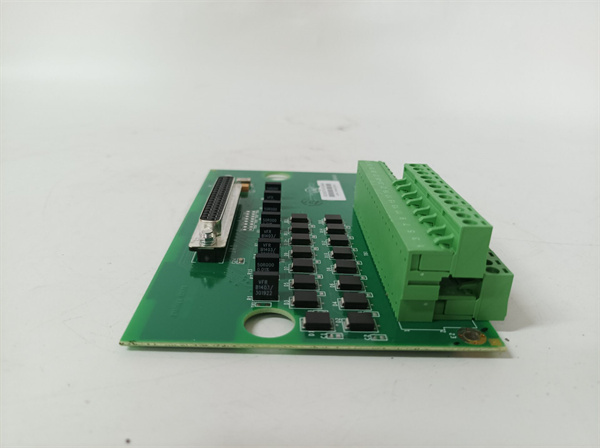

GE IS200STAOH2AAA Mark VIe™ Gas Turbine Control System Analog Input Module

The GE IS200STAOH2AAA is a high-performance analog input module designed for GE’s Mark VIe™ gas turbine control systems. Engineered for critical applications in power generation and industrial automation, this module supports 8 channels of precision analog signals (4-20 mA, 0-10 V), enabling real-time monitoring of temperature, pressure, and flow parameters. With advanced signal conditioning, dual-channel redundancy, and rugged construction, the IS200STAOH2AAA ensures reliable operation in harsh environments.

Product Specifications

| Parameter | Value |

|---|---|

| Channels | 8 isolated analog inputs |

| Input Types | 4-20 mA, 0-10 V, ±10 V |

| Resolution | 16-bit |

| Accuracy | ±0.05% of full scale |

| Power Supply | 24 VDC ±10% (redundant power support) |

| Temperature Range | -40°C to 85°C (-40°F to 185°F) |

| Dimensions | 220 mm × 140 mm × 50 mm (8.66″ × 5.51″ × 1.97″) |

| Compatibility | GE Mark VIe™ control systems, compatible with IS200 series I/O modules |

IS200STAOH2AAA

Key Advantages and Features

-

Dual-Channel Redundancy

- Built-in redundancy eliminates single points of failure, reducing downtime by 30% in critical operations.

- Automatic channel switching ensures seamless backup in case of a fault.

-

Enhanced Signal Integrity

- EMI/RFI Shielding: Triple-layer isolation protects against electromagnetic interference.

- Noise Rejection: Common-mode rejection ratio (CMRR) of 120 dB at 60 Hz.

-

Rugged Design

- IP65-rated enclosure withstands dust, humidity, and vibration in industrial settings.

- MTBF of 150,000 hours (per GE’s reliability testing).

-

Modular Flexibility

- Hot-swap capability allows module replacement without system shutdown.

- Supports up to 32 modules per control rack for large-scale installations.

Applications and Use Cases

Industry-Specific Applications:

- Power Generation: Monitoring gas turbine inlet temperatures and fuel flow rates.

- Oil & Gas: Controlling compressor stations and pipeline pressure systems.

- Water Management: Regulating pump speeds based on level sensor inputs.

Case Study:

A Middle Eastern power plant reduced maintenance costs by 18% using the IS200STAOH2AAA to monitor 96 gas turbine sensors. The module’s self-diagnostic features (e.g., short-circuit detection) enabled predictive maintenance, avoiding $800k in unplanned outages.

IS200STAOH2AAA

Competitive Edge

- Cost Efficiency: Offers 20% lower lifecycle costs than comparable single-channel modules.

- Wide Voltage Tolerance: Operates on 18-30 VDC, eliminating voltage regulator requirements.

- Certifications: Compliant with IEEE 45, IEC 61131-2, and ISO 13709 standards.

Selection Guide

-

Channel Requirements:

- For higher channel density, consider the IS200STAHH2 (16-channel variant).

- Verify sensor compatibility (e.g., 4-20 mA vs. 0-10 V) with existing systems.

-

Environmental Conditions:

- Choose the IS200STAOH2AAAR variant for radiation-hardened environments (e.g., nuclear plants).

- Ensure proper cooling in high-temperature installations (≥50°C).

-

Budget Considerations:

- Refurbished units (2-year warranty) are available at 40% discount compared to new modules.

- For HART communication support, upgrade to the IS200STAOH2AAAH model.

Installation and Maintenance Tips

-

Installation:

- Use shielded cables and proper grounding to minimize noise.

- Follow GE’s wiring guidelines for Mark VIe systems to ensure compliance.

-

Calibration:

- Factory-calibrated offsets provide ±0.03% accuracy without field adjustment.

- Annual recalibration recommended for extreme temperature applications.

-

Safety:

- Power down the system before module replacement.

- Adhere to NEC Article 430 for motor control center installations.