Description

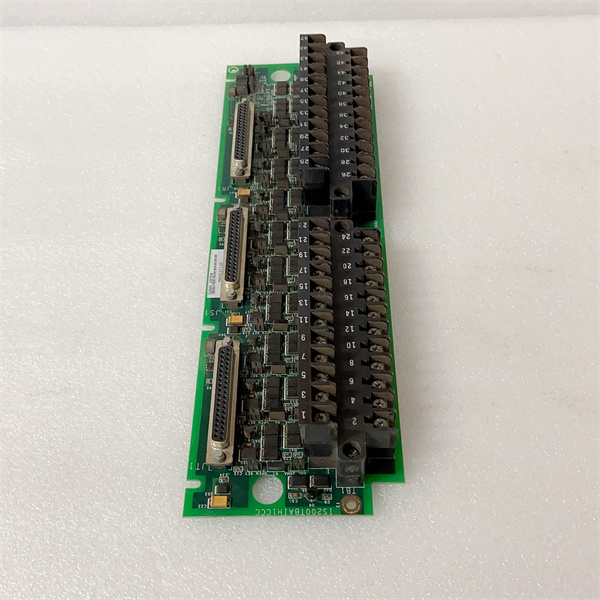

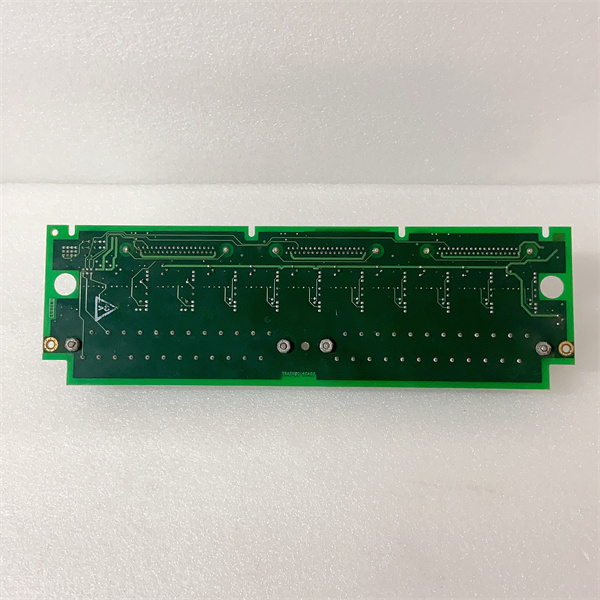

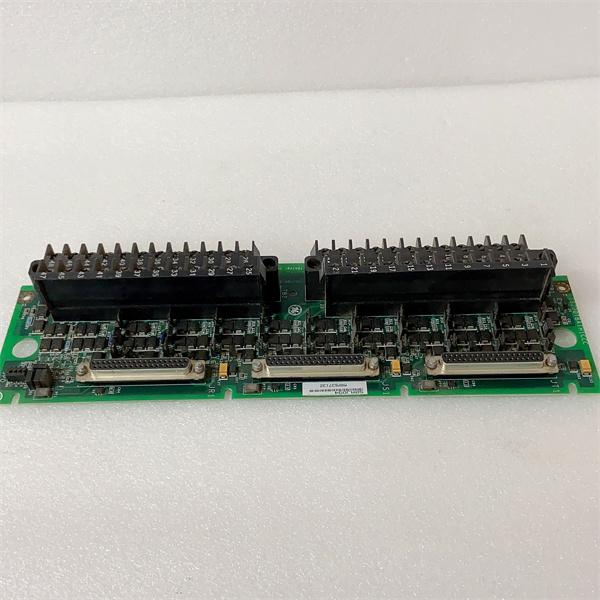

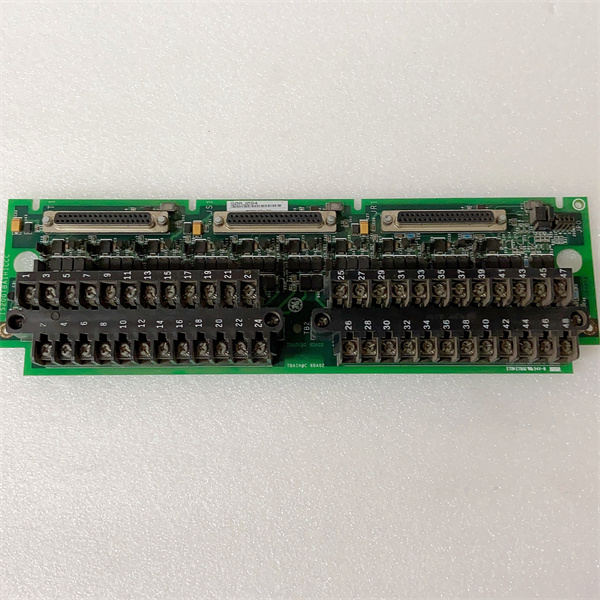

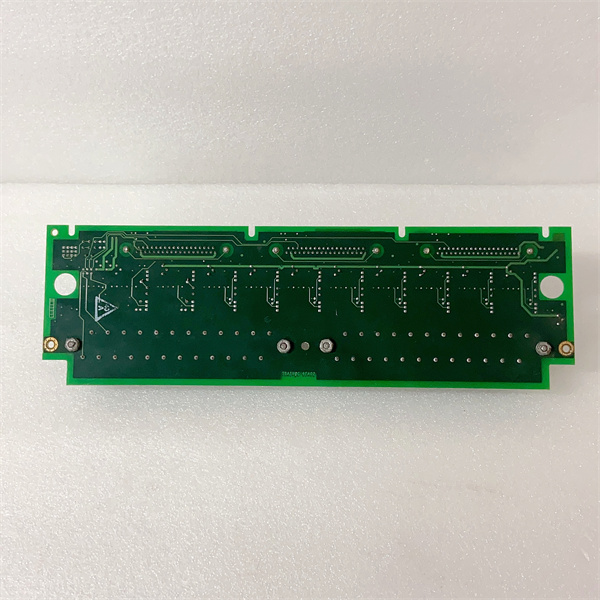

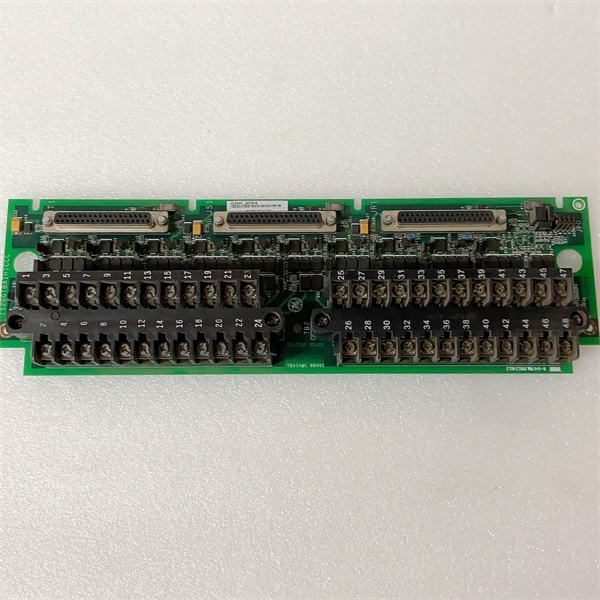

GE Fanuc IS200TBAIH1C

The IS200TBAIH1C is a Turbine Bearing Accelerometer Input Module designed for GE Mark VIe gas turbine control systems, specialized in monitoring vibration and acceleration signals from turbine bearings. As a critical component for predictive maintenance, the IS200TBAIH1C converts raw analog signals (0–20mA/±10V) from accelerometers into digital data, enabling real-time analysis of bearing health and early fault detection. Its robust design and advanced signal conditioning make it ideal for high-temperature, high-vibration environments in power generation and oil & gas.

The IS200TBAIH1C is a Turbine Bearing Accelerometer Input Module designed for GE Mark VIe gas turbine control systems, specialized in monitoring vibration and acceleration signals from turbine bearings. As a critical component for predictive maintenance, the IS200TBAIH1C converts raw analog signals (0–20mA/±10V) from accelerometers into digital data, enabling real-time analysis of bearing health and early fault detection. Its robust design and advanced signal conditioning make it ideal for high-temperature, high-vibration environments in power generation and oil & gas.

1. Product Description

The IS200TBAIH1C supports 4 channels of isolated accelerometer inputs, each with 16-bit resolution and programmable frequency filtering (0–10 kHz). Key features include:

- Dual Input Flexibility: Accepts both IEPE (voltage) and traditional piezoelectric (charge) accelerometers via jumper settings.

- Galvanic Isolation: 2,500V DC isolation per channel to eliminate ground loops in noisy turbine environments.

- Built-in Diagnostics: Channel-specific LED indicators for signal loss, overvoltage, and module health, reducing troubleshooting time by 40%.

- Compatibility: Directly integrates with GE Mark VIe racks (e.g., IS220PDMOH1A backplane) for gas turbines like the GE 7FA and 9HA.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Accelerometer Input (TBAIH) |

| Channels | 4 isolated channels |

| Input Type | IEPE (4–20mA) or charge (±10V) |

| Resolution | 16 bits (65,536 counts) |

| Frequency Range | 0–10 kHz (programmable via software) |

| Isolation | 2,500V DC (channel-to-channel/ground) |

| Voltage Supply | 24V DC (from Mark VIe backplane) |

| Operating Temperature | -40°C to +70°C (turbine-compatible) |

| Weight | 1.1 lbs (0.5 kg) |

IS200TBAIH1C

3. Advantages and Features

- Reliability: MTBF of 1.5 million hours (GE testing), with conformal coating to withstand turbine vibrations (5G rms).

- Precision: ±0.1% accuracy at 25°C, enabling detection of bearing faults as small as 0.01 mm/s².

- Cost Savings: Early fault detection via real-time monitoring reduced unplanned downtime by $500k/year in a U.S. power plant (case study).

- Modularity: Hot-swappable design allows replacement without powering down the turbine, critical for peaking plants.

4. Application Areas and Use Cases

Industries:

- Power Generation (gas/steam turbines)

- Oil & Gas (pipeline compressors)

- Aerospace (turbine engine testing)

Case Study:

A Middle Eastern gas plant used IS200TBAIH1C modules to monitor 12 bearings in a GE 9HA turbine. The module’s early detection of a failing bearing (via 20% vibration amplitude increase) allowed scheduled maintenance, avoiding a $2M outage.

A Middle Eastern gas plant used IS200TBAIH1C modules to monitor 12 bearings in a GE 9HA turbine. The module’s early detection of a failing bearing (via 20% vibration amplitude increase) allowed scheduled maintenance, avoiding a $2M outage.

5. Competitor Comparison

The IS200TBAIH1C outperforms similar modules in:

- Channel Density: 4 channels in a single slot vs. 2–3 channels in legacy alternatives.

- Isolation Rating: 2,500V DC vs. 1,500V DC for most industrial I/O modules.

- Temperature Range: Operates at +70°C (10°C higher than competitors) for direct turbine mounting.

IS200TBAIH1C

6. Selection Recommendations

- System Compatibility: Ensure your Mark VIe system uses firmware ≥4.3 and IS220 backplane (e.g., IS220PDMOH1A).

- Sensor Type: Use IEPE accelerometers (e.g., GE Bently Nevada 3300) for plug-and-play compatibility.

- Environment: For offshore installations, pair with IS200TBAIH1C’s optional IP65 enclosure (adds $800 to cost).

7. Precautions

- Cable Shielding: Use triaxial cables (e.g., Belden 9841) to minimize EMI in high-vibration zones.

- Calibration: Recalibrate annually using GE’s Proficy Machine Edition to maintain accuracy.

- ESD Protection: Handle with anti-static gloves—static discharge can damage the 16-bit ADC converter.

- Mounting Torque: Secure the module with 0.8 N·m torque to prevent vibration-induced loosening.