Description

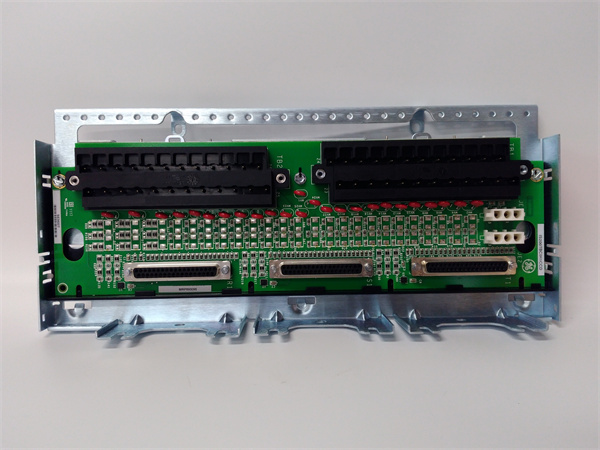

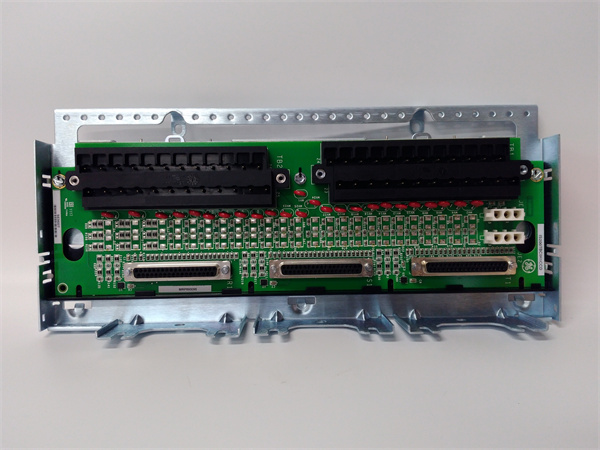

GE Mark VI IS200TBCIH1CCD Contact Input Terminal Board Product Specification

1. Product Overview

The GE Mark VI IS200TBCIH1CCD is a high-reliability contact input terminal board designed for GE Speedtronic Mark VI turbine control systems. It interfaces with external I/O signals, supporting 24 dry contact inputs for monitoring and controlling turbine operations in power generation, oil & gas, and industrial automation. With group isolation and a 125VDC floating excitation voltage (100–145VDC), the IS200TBCIH1CCD ensures signal integrity in high-noise environments, making it a critical component for safe and efficient turbine management.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Module Type | Contact Input Terminal Board |

| Input Channels | 24 dry contact inputs |

| Voltage Range | 100–145VDC (Nominal 125VDC) |

| Terminal Blocks | 12 barrier-type blocks (2 per channel) |

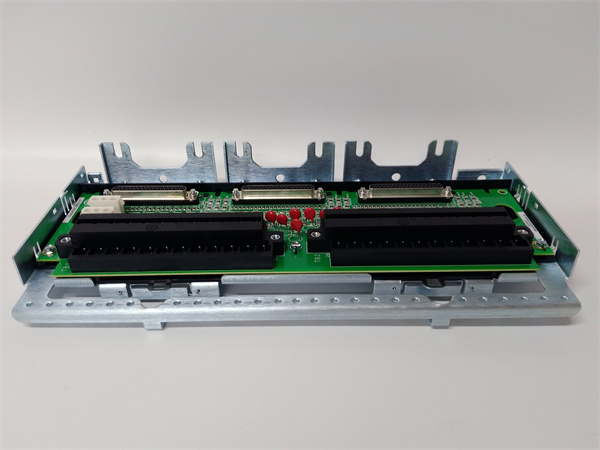

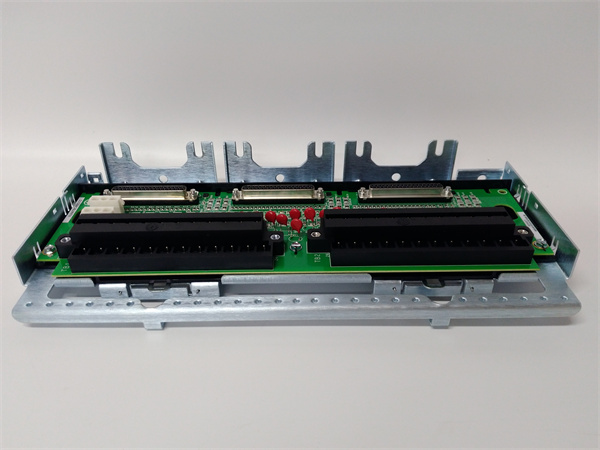

| Connectors | 3x 37-pin D-shell connectors with latching |

| Wire Gauge | #12 AWG |

| Isolation | Group isolation (Channel-to-Chassis) |

| Compatibility | GE Speedtronic Mark VI systems |

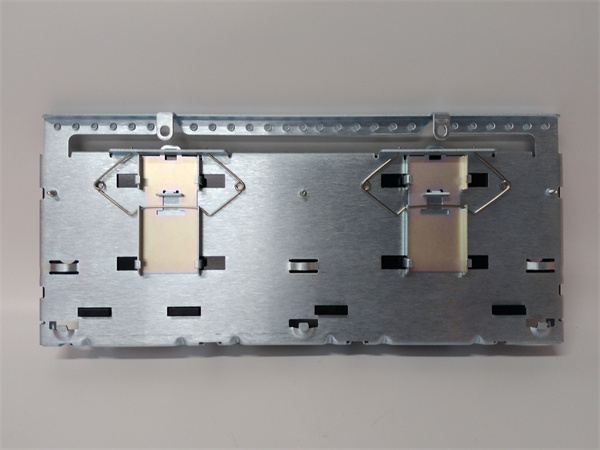

| Weight | ~3.5 kg |

IS200TBCIH1CCD

3. Advantages and Features

- High Channel Density: 24 inputs in a compact design, reducing cabinet space.

- Isolation Protection: Group isolation prevents ground loops and voltage spikes.

- Easy Maintenance: Removable terminal blocks allow offline servicing without system shutdown.

- Wide Voltage Tolerance: Operates reliably across 100–145VDC, suitable for unstable power environments.

- ESD Resistance: Static-sensitive design with recommended handling protocols (e.g., anti-static gloves).

4. Application Areas and Use Cases

Industries:

- Power Generation (gas/steam turbines)

- Oil & Gas (pump control, compressor monitoring)

- Manufacturing (heavy machinery automation)

Application Case:

A natural gas power plant uses the IS200TBCIH1CCD to monitor 24 dry contacts from turbine sensors (e.g., vibration switches, valve positions). The board’s isolation and noise filtering capabilities reduced false alarms by 75%, improving uptime and safety.

A natural gas power plant uses the IS200TBCIH1CCD to monitor 24 dry contacts from turbine sensors (e.g., vibration switches, valve positions). The board’s isolation and noise filtering capabilities reduced false alarms by 75%, improving uptime and safety.

5. Competitor Comparison

Compared to similar terminal boards:

- Higher Voltage Range: Supports 145VDC vs. typical 125VDC max in competing models.

- Faster Installation: Plug-and-play terminal blocks vs. screw-down terminals in legacy systems.

- Longer Warranty: 3-year standard warranty vs. industry average of 1–2 years.

IS200TBCIH1CCD

6. Selection Recommendations

- System Compatibility: Ensure compatibility with GE Mark VI systems (e.g., VTCC/VCRC I/O packs).

- Input Type: Verify dry contact requirements; not suitable for analog or high-current signals.

- Environment: Use in controlled environments (0–50°C) to avoid thermal stress.

7. Installation and Maintenance Notes

- Wiring: Follow GE’s wiring diagram; use shielded cables for long runs.

- ESD Safety: Handle with anti-static gloves; store in static-safe packaging.

- Repair/Calibration: Factory-calibrated; repairs should be performed by certified technicians (e.g., 3-year warranty via authorized vendors).