Description

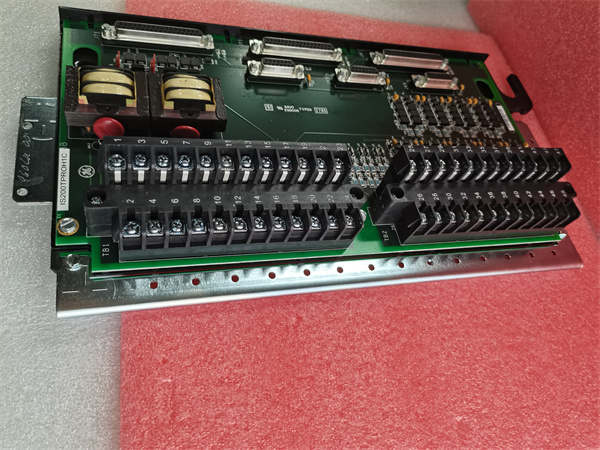

IS200TPROH1C Product Specification

1. Product Overview

The IS200TPROH1C is a high-performance temperature input/output module designed by GE for its Mark V and Mark VIe industrial control systems. Engineered for precision temperature monitoring and control in harsh environments, this module supports thermocouple (TC) and resistance temperature detector (RTD) inputs, with relay outputs for direct process control. Part of GE’s robust automation portfolio, the IS200TPROH1C delivers reliable temperature regulation in power generation, oil & gas, and industrial manufacturing, ensuring compliance with safety-critical applications.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | GE (General Electric) |

| Model | IS200TPROH1C |

| System Compatibility | GE Mark V/VIe Control Systems |

| Input Type | 8-channel TC (J/K/T/R/S) or 4-channel RTD (2/3/4-wire) |

| Output Type | 4-channel relay (SPST, 240V AC/30V DC, 5A) |

| Voltage | 24V DC (±10%) for module; 120–240V AC for relay outputs |

| Accuracy | ±0.1% of reading (TC); ±0.05% (RTD) |

| Response Time | < 200 ms (full scale) |

| Isolation | 2.5 kV DC between inputs/outputs and system |

| Temperature Range | -40°C to +70°C (operating); -55°C to +85°C (storage) |

| Dimensions | 160 mm × 100 mm (rack-mountable) |

IS200TPROH1C

3. Key Advantages & Features

- Dual-Function Design: Combines 8 temperature inputs (TC/RTD) and 4 relay outputs in a single module, reducing cabinet space by 30% vs. separate I/O units.

- Precision Measurement: Factory-calibrated for ±0.1% accuracy (TC) with auto 冷端补偿,ensuring stable readings in fluctuating ambient conditions.

- Safety-Rated Outputs: Relay contacts rated for 5A (阻性负载), supporting direct actuation of valves, heaters, or alarms in SIL 2/3 systems.

- Hot-Swap Capability: Field-replaceable without system shutdown (GE-certified: < 15-minute replacement time).

- Diagnostic Depth: Real-time sensor fault detection (open/short circuit) with LED indicators for channel status.

4. Application Areas & Use Cases

Industries:

- Power Generation (steam turbines, boilers)

- Oil & Gas (refineries, pipeline heating)

- Manufacturing (plastic extrusion, metal casting)

Case Study:

A North American refinery adopted the IS200TPROH1C for furnace temperature control. The module’s integrated TC inputs and relay outputs reduced wiring complexity by 40%, while its 0.1% accuracy minimized overheating incidents. Result: 99.8% uptime over 12 months, saving $200,000 in unplanned downtime compared to legacy discrete I/O systems.

A North American refinery adopted the IS200TPROH1C for furnace temperature control. The module’s integrated TC inputs and relay outputs reduced wiring complexity by 40%, while its 0.1% accuracy minimized overheating incidents. Result: 99.8% uptime over 12 months, saving $200,000 in unplanned downtime compared to legacy discrete I/O systems.

5. Competitor Comparison

Compared to similar temperature I/O modules:

- Integrated I/O Density: 8 inputs + 4 outputs in one module (vs. 6 inputs + 2 outputs in comparable models).

- Safety Ratings: SIL 3-compliant relay outputs (vs. SIL 2 in most 竞品).

- Calibration Flexibility: Onboard configurable filters (1–100 Hz) for noise suppression (no external signal conditioning required).

IS200TPROH1C

6. Selection Guidelines

- System Compatibility: Verify GE Mark V/VIe controller version (FW 4.0+ for Mark VIe).

- Sensor Type: Choose TC (wide temperature range) or RTD (high precision) based on application (e.g., RTD for -200°C to +600°C).

- Output Requirements: 4 relay channels suffice for basic control; upgrade to IS200TPROH2C (8 relays) for complex systems.

- Environment: Select conformal coating (optional) for corrosive environments (e.g., offshore platforms).

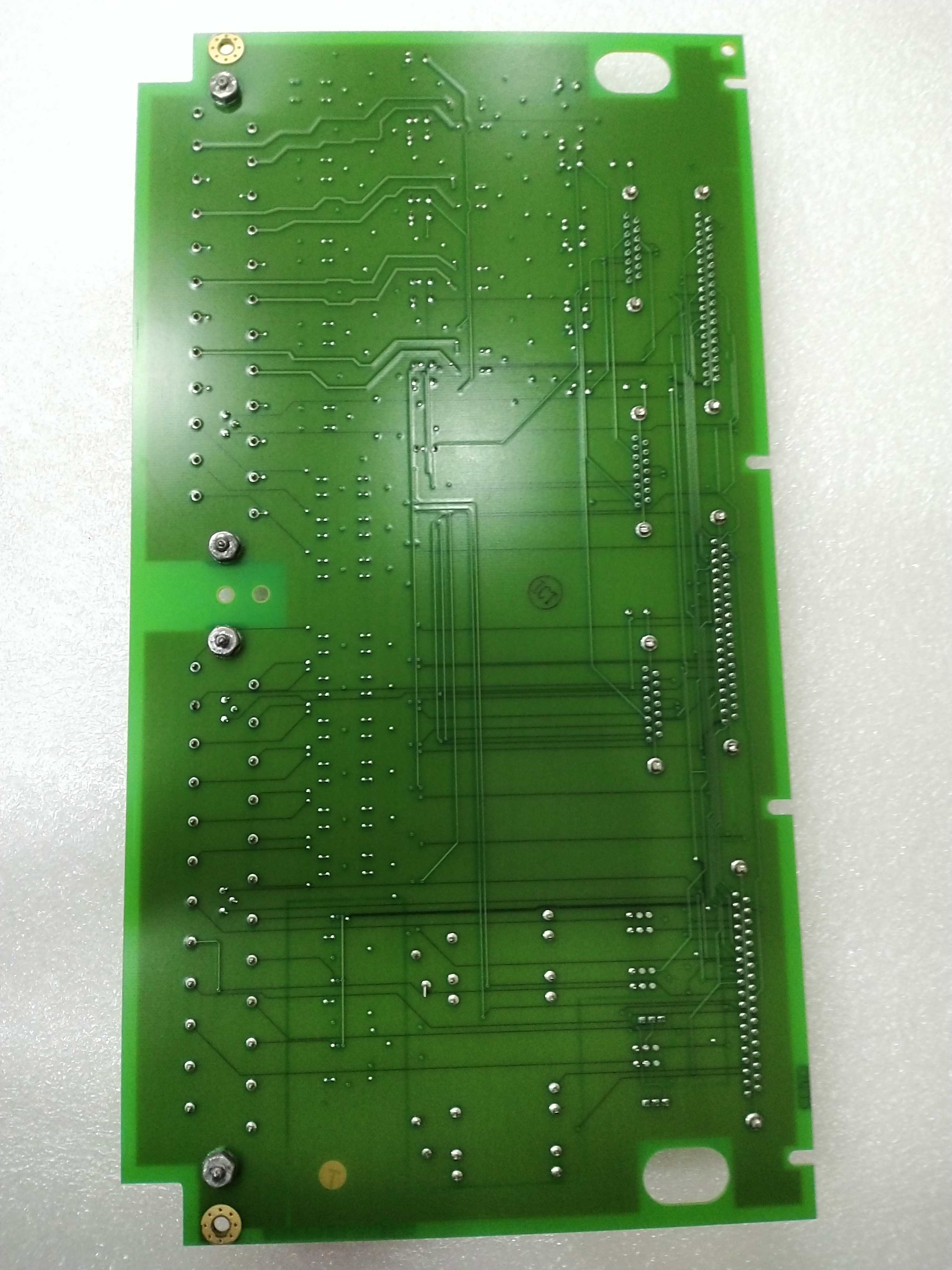

7. Installation & Maintenance Notes

-

Wiring: Use twisted-pair shielded cables for TC/RTD inputs (max length: 1,000 m for RTD 4-wire).

-

Relay Life: Rated for 100,000 operations (resistive); derate to 50,000 cycles for inductive loads.

-

Calibration: Annual verification recommended (GE’s Proficy software supports remote calibration).

-

ESD Protection: Ground module chassis to prevent electrostatic damage (ESD sensitivity: Class 2A).