Description

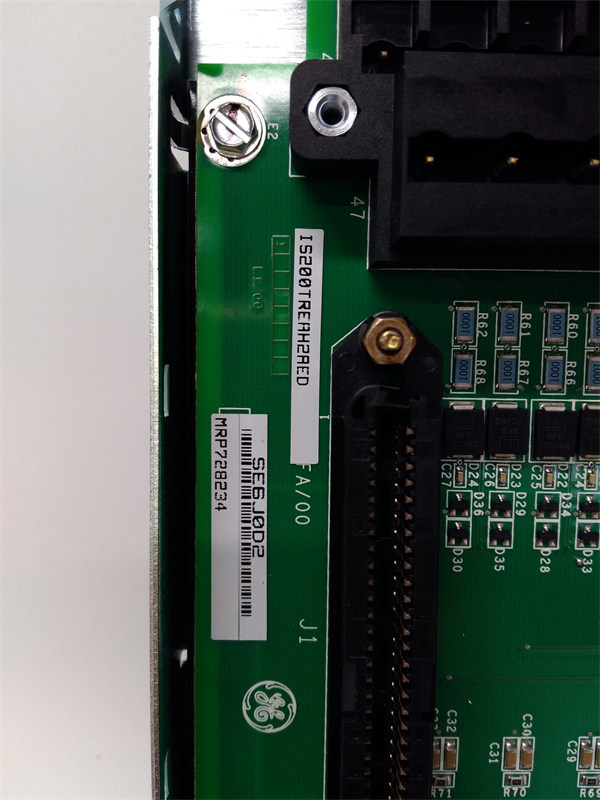

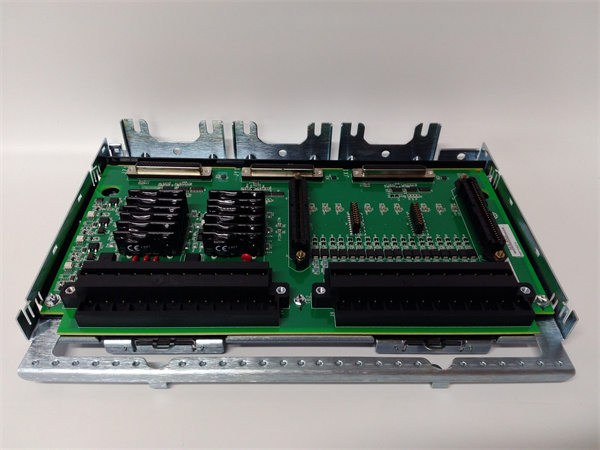

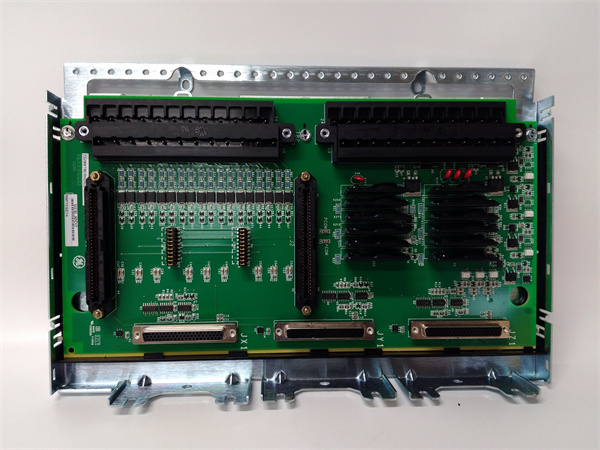

GE Fanuc IS200TREAH2AED Product Specification

1. Product Overview

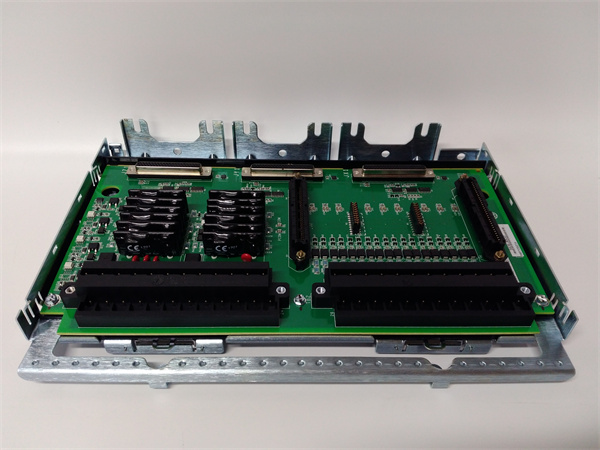

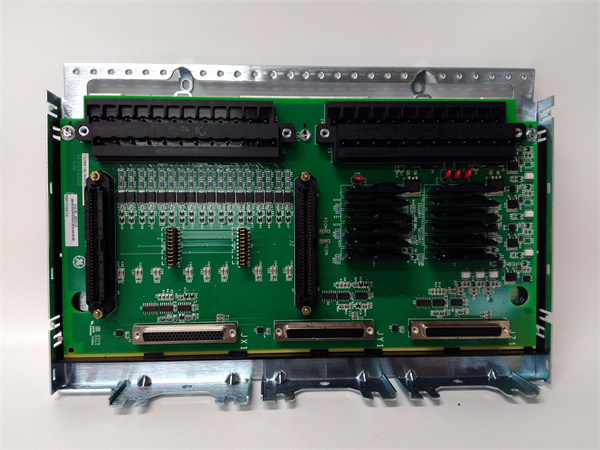

The GE Fanuc IS200TREAH2AED is a high-precision analog input module designed for industrial automation systems, compatible with GE Fanuc PACSystems RX3i and RX7i platforms. This module specializes in converting thermocouple (TC) and RTD signals from temperature sensors into digital data for real-time process control. With advanced signal conditioning and built-in diagnostics, the IS200TREAH2AED ensures accurate temperature monitoring in harsh environments, making it ideal for applications requiring reliable thermal management.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Module Type | Thermocouple/RTD Input Module |

| Input Types | J, K, T, E, R, S, B thermocouples; 2/3/4-wire RTD |

| Number of Channels | 8 channels |

| Voltage Range | 24V DC (±15%) |

| Accuracy | ±0.1% of reading (Thermocouple); ±0.2°C (RTD) |

| Isolation | 500Vrms (Channel-to-Chassis) |

| Compatibility | GE Fanuc PACSystems RX3i/RX7i |

| Temperature Range | -40°C to 125°C (Module); -200°C to 1800°C (Sensors) |

IS200TREAH2AED

3. Advantages and Features

- Dual Sensor Compatibility: Supports both thermocouples and RTDs on the same module, reducing inventory costs.

- Auto-Ranging Inputs: Automatically detects sensor types, eliminating manual configuration errors.

- Enhanced Noise Filtering: 60/50 Hz notch filtering ensures stable readings in high-interference environments.

- Advanced Diagnostics: Real-time sensor fault detection (open circuit, short circuit) with LED indicators.

- Wide Temperature Range: Operates reliably in extreme conditions, from cryogenic to high-temperature industrial settings.

4. Application Areas and Use Cases

Industries:

- Petrochemical (reactor temperature control)

- Food and Beverage (pasteurization systems)

- Aerospace (engine testing)

- HVAC (commercial heating systems)

Application Case:

A petrochemical plant uses the IS200TREAH2AED to monitor 8 thermocouples in a distillation column. The module’s auto-ranging and noise filtering capabilities reduced measurement errors by 90%, improving product quality and safety.

A petrochemical plant uses the IS200TREAH2AED to monitor 8 thermocouples in a distillation column. The module’s auto-ranging and noise filtering capabilities reduced measurement errors by 90%, improving product quality and safety.

5. Competitor Comparison

Compared to similar temperature input modules, the IS200TREAH2AED offers:

- Higher Channel Density: 8 channels vs. typical 4–6 channels in competing models.

- Faster Response Time: 250 ms update rate vs. 500 ms in legacy systems.

- Lower Power Consumption: 1.2W per channel vs. 1.5W industry average.

IS200TREAH2AED

6. Selection Recommendations

- Sensor Type: Verify compatibility with your thermocouple/RTD types (e.g., K-type for general industrial use).

- Environment: Ensure the module’s operating temperature (-40°C to 70°C) matches your installation conditions.

- Scalability: Pair with GE Fanuc’s PACSystems for seamless integration with PLCs and HMIs.

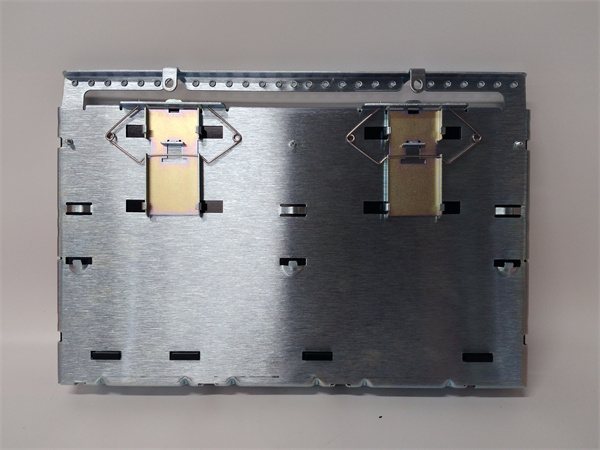

7. Installation and Maintenance Notes

- Wiring: Use shielded cables for thermocouple inputs; avoid long wire runs for RTDs to minimize resistance errors.

- Calibration: Factory-calibrated; re-calibrate every 2 years for critical applications.

- Safety: Disconnect power before replacing the module to prevent electric shock.