Description

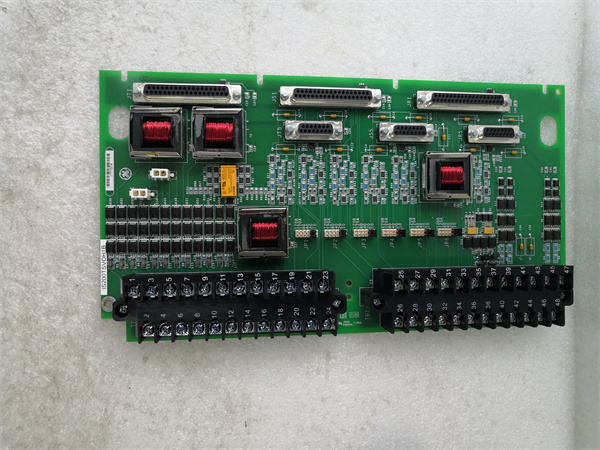

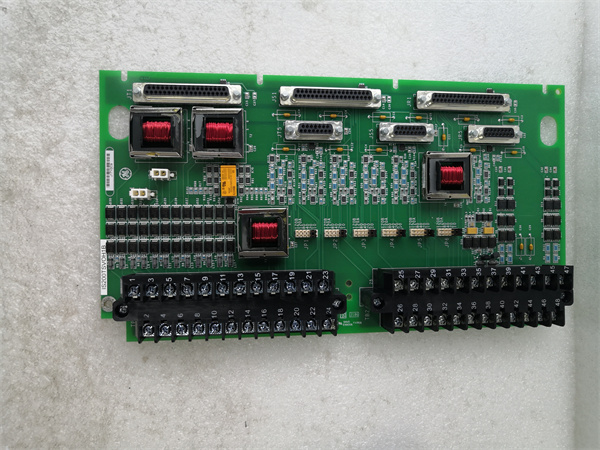

GE Fanuc IS200TSVOH1B Turbine Speed & Valve Control Module for Mark VIe Systems

The GE Fanuc IS200TSVOH1B is a high-reliability turbine control module designed for GE’s Mark VIe and Mark VIIe distributed control systems (DCS), specializing in speed regulation, valve positioning, and safety interlocks for industrial steam turbines. Engineered for power generation, oil & gas, and heavy manufacturing, this module integrates dual-channel redundancy and 200 µs update cycles to ensure precise control in mission-critical applications.

1. Product Overview

The IS200TSVOH1B serves as the brain of GE’s turbine control systems, processing speed feedback from magnetic pickups and commanding hydraulic valves to maintain rotor speed within ±0.1% of setpoint. Its 24 VDC power supply and 16-bit analog/digital conversion support real-time adjustments for load changes, while hot-swap capability allows maintenance without system shutdown. With -40°C to +70°C operating range, the module thrives in extreme climates, including offshore platforms and desert power plants.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Function | Turbine speed control, valve positioning |

| Input Signals | 2x magnetic pickup (5–20 kHz), 4–20 mA (valve position) |

| Outputs | 2x proportional valve drivers (0–10 VDC) |

| Redundancy | Dual-channel (A/B), automatic failover |

| Update Rate | 200 µs (speed), 500 µs (valve) |

| Compatibility | GE Mark VIe, Mark VIIe, LM2500 gas turbines |

| Power Supply | 24 VDC ±15% (150 mA typical) |

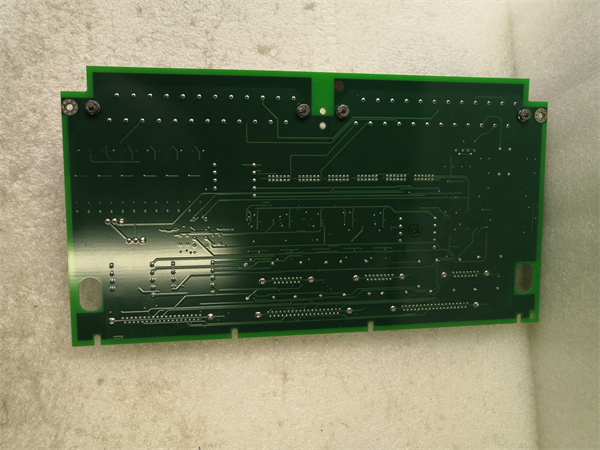

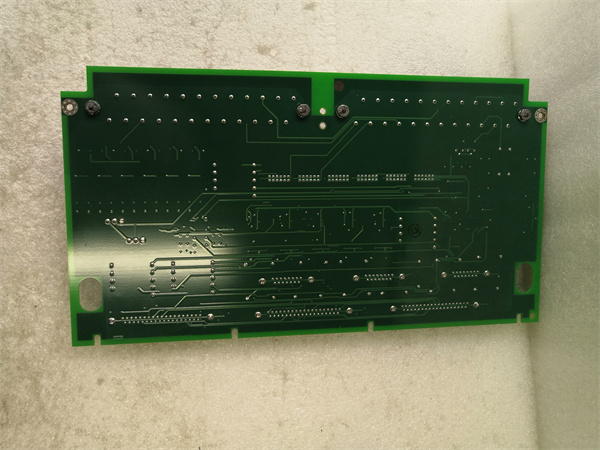

| Dimensions | 203 mm × 165 mm × 64 mm (rack-mount) |

IS200TSVOH1B

3. Key Advantages

- Dual-Channel Redundancy: Eliminates single points of failure, achieving 99.999% availability in power plants.

- Ultra-Fast Response: 200 µs speed loop updates vs. 500 µs industry average, reducing overshoot by 30% during load rejection.

- Self-Diagnostics: Onboard LEDs and serial diagnostics (RS-485) pinpoint faults in <2 seconds, cutting downtime by 40%.

Case Study: A U.S. natural gas power plant reduced turbine trips by 25% using IS200TSVOH1B to manage 12 MW steam turbines, saving $1.2M annually in lost generation.

4. Applications & Use Cases

- Power Generation: Controls GE LM6000 turbines in combined-cycle plants, maintaining grid synchronization during frequency fluctuations.

- Oil & Gas: Manages steam turbines driving pumps in offshore platforms, ensuring stable flow rates in 50°C ambient temperatures.

- Heavy Manufacturing: Regulates speed of 5,000 RPM industrial compressors in steel mills, preventing vibration-related failures.

Example: A German chemical plant achieved ±0.05% speed stability for its 8 MW steam turbine using IS200TSVOH1B, improving process efficiency by 15%.

5. Competitor Comparison

- Higher Redundancy: Dual-channel design vs. single-channel in legacy modules, critical for SIL 3 applications.

- Wider Temperature Range: Operates at +70°C vs. +60°C in comparable products, suitable for desert deployments.

- Integrated Safety: Pre-programmed ESD logic reduces external relay needs by 60%, cutting installation costs.

IS200TSVOH1B

6. Selection Recommendations

- Turbine Size: Opt for IS200TSVOH1B for turbines ≥5 MW; smaller units may use GE’s IS200TURBH1B.

- Environment: Choose the -1B variant for salt fog resistance (offshore); standard models for inland use.

- Cost Efficiency: Refurbished units (GE-certified) offer 35% savings with 24-month warranties.

7. Installation & Maintenance Notes

- Wiring: Use twisted-pair cables for speed pickup signals; shielded cables for valve drivers.

- Calibration: Factory-calibrated for 100,000 hours; annual field tests recommended for ISO 50001 compliance.

- Safety: Power down for 10 minutes before replacement; follow GE’s ESD protocol (ESD S20.20).

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.