Description

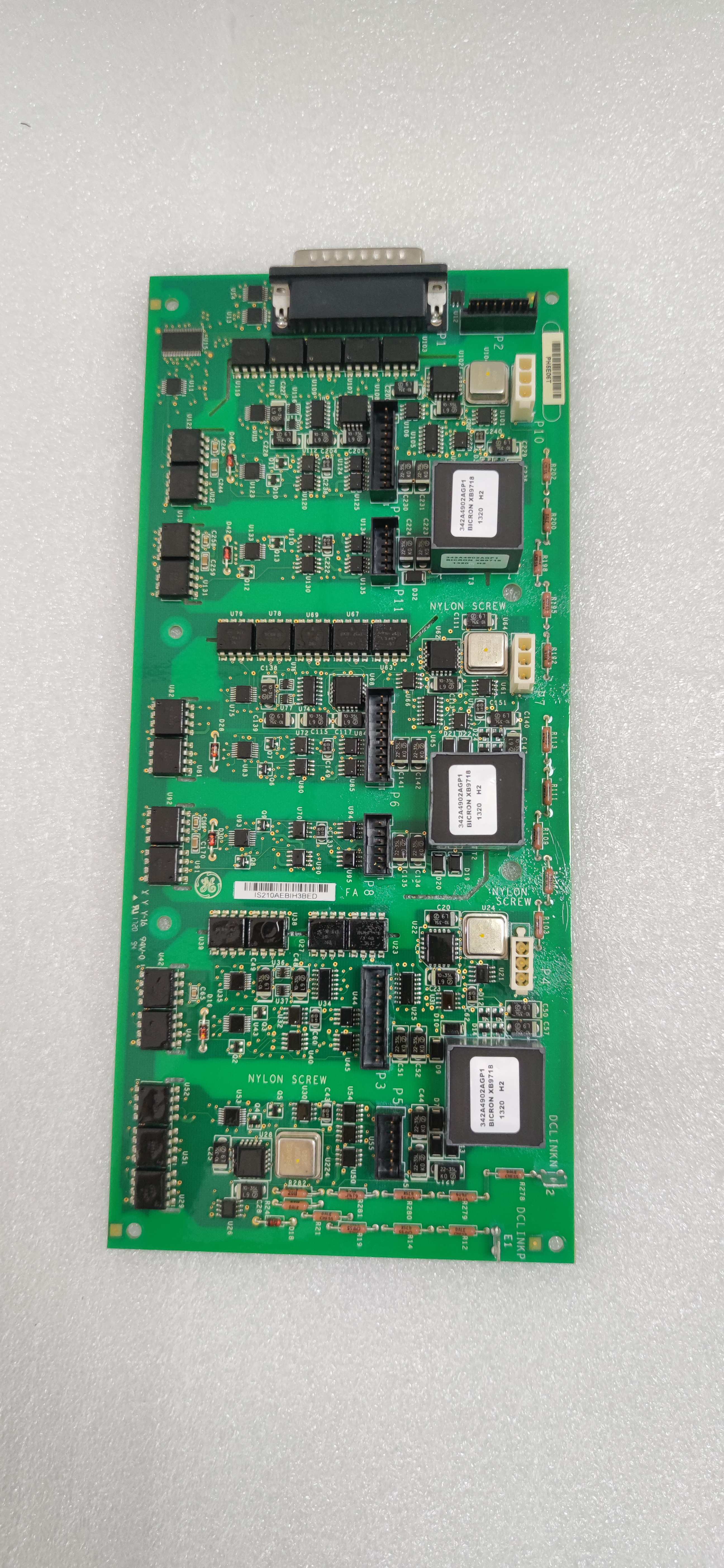

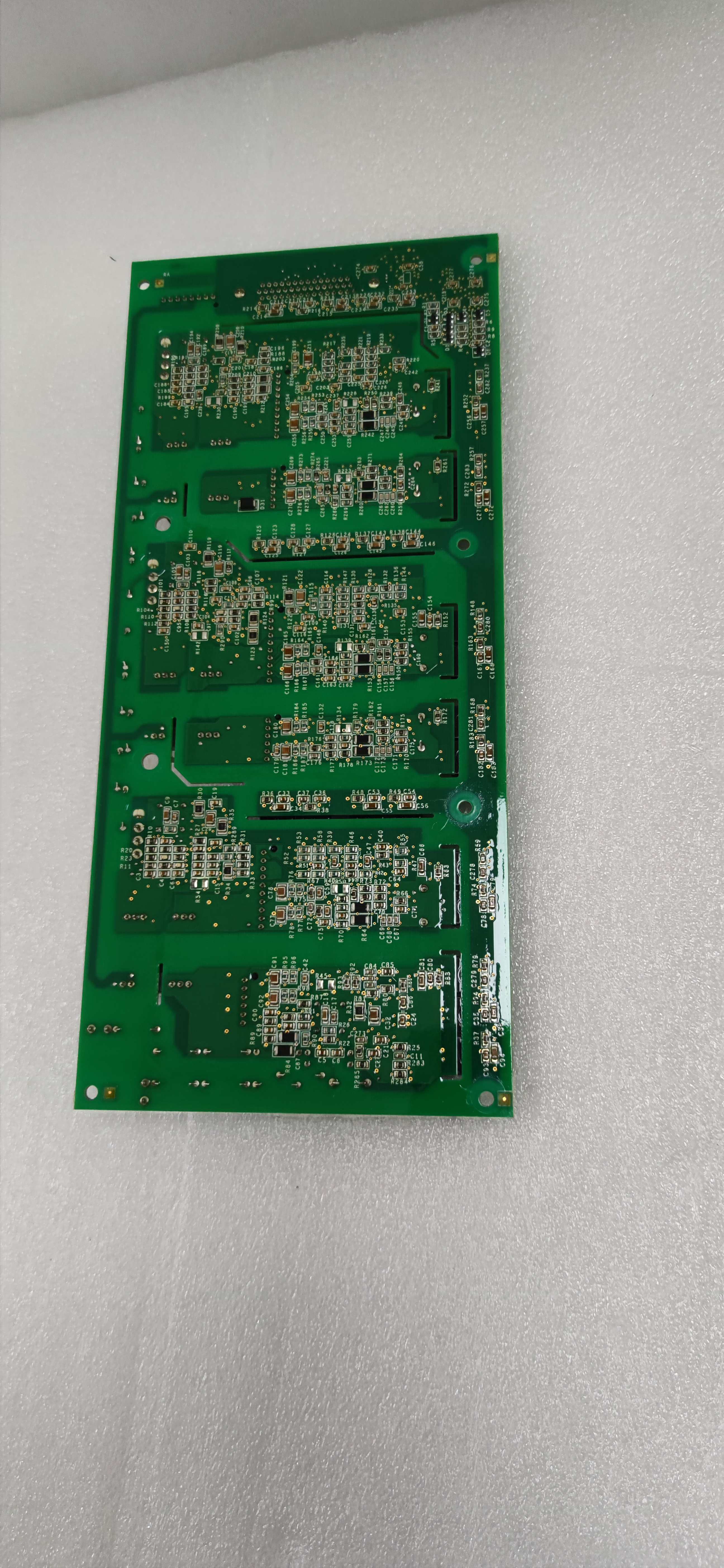

Product Description: GE IS210AEBIH3BED Alternative Energy Bridge Interface Module

The GE IS210AEBIH3BED is a high-reliability printed circuit board (PCB) designed for GE’s Mark VIe series of wind turbine control systems. Serving as an Alternative Energy Bridge Interface (AEBI), this module facilitates seamless communication between renewable energy sources and grid infrastructure. It features a conformal coating for protection against environmental stressors, ensuring durability in harsh industrial settings. The IS210AEBIH3BED integrates advanced DC-DC conversion technology (24V DC input to 5V DC output, 3A max current), combining power management with communication capabilities for applications in energy generation, industrial automation, and grid stabilization.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | IS210AEBIH3BED (GE Mark VIe Series) |

| Manufacturer | GE Energy |

| Function | Alternative Energy Bridge Interface (AEBI) |

| Voltage Input | 24V DC |

| Voltage Output | 5V DC (3A max current) |

| PCB Coating | Conformal (environmental protection) |

| Certifications | CE, FCC (international safety standards) |

| Compatibility | GE Mark VIe wind turbine control systems |

| Protection Features | Input/output overvoltage/overcurrent protection |

| Efficiency | High-efficiency DC-DC conversion (>90%) |

| Operating Temperature | -40°C to +70°C (industrial grade) |

IS210AEBIH3BED

3. Advantages and Features

- Robust Environmental Protection: Conformal coating shields against moisture, dust, and vibration, extending lifespan in offshore/onshore wind farms.

- Integrated Power and Communication: Combines DC-DC power conversion with bridge interface functionality for compact system design.

- Safety and Compliance: CE/FCC certifications ensure adherence to global safety standards.

- Reliable Performance: Input/output protection prevents equipment damage during voltage fluctuations.

- High Efficiency: Low power loss (<10%) reduces operational costs in renewable energy installations.

- Case Study: A European wind farm reduced downtime by 15% using the IS210AEBIH3BED, achieving 99.5% system availability in high-humidity conditions.

4. Application Areas and Use Cases

Industries:

- Renewable energy (wind/solar power generation)

- Industrial automation (power management systems)

- Grid stabilization (smart grid infrastructure)

Use Case:

A wind farm in the U.S. deployed the IS210AEBIH3BED to interface between turbine generators and grid controllers. The module’s conformal coating and surge protection minimized failures in coastal environments, improving energy transfer efficiency by 8% and lowering maintenance costs by 25%.

A wind farm in the U.S. deployed the IS210AEBIH3BED to interface between turbine generators and grid controllers. The module’s conformal coating and surge protection minimized failures in coastal environments, improving energy transfer efficiency by 8% and lowering maintenance costs by 25%.

5. Competitive Comparison

Compared to similar interface modules:

- Superior Environmental Resilience: Conformal coating (vs. standard coatings in 竞品) ensures longer life in corrosive/harsh environments.

- Dual Functionality: Integrates power conversion and communication (vs. separate modules in 竞品), reducing system complexity.

- Safety Compliance: CE/FCC certifications (vs. regional-only certifications in some 竞品) enable global deployment.

- Efficiency: Higher conversion efficiency (90%+ vs. 85% avg. in 竞品) lowers energy waste.

IS210AEBIH3BED

6. Selection Recommendations

- Compatibility: Ensure alignment with GE Mark VIe systems and renewable energy infrastructure.

- Power Requirements: Verify input/output voltage (24V DC to 5V DC) matches system needs.

- Environment: Choose for applications with high humidity, dust, or vibration (e.g., offshore wind).

- Scalability: Ideal for medium-to-large energy projects requiring reliable grid integration.

7. Precautions

- Installation:

- Use ESD protection (anti-static wristband) during handling.

- Ensure proper grounding and ventilation (cabinet temperature ≤50°C).

- Operation:

- Monitor input voltage stability (±10% tolerance for 24V DC).

- Avoid overloading (max 3A output current).

- Maintenance:

- Inspect conformal coating for damage annually.

- Replace modules every 7–10 years (based on GE’s recommended lifecycle).

- Safety:

- Disconnect power before troubleshooting.

- Follow NEC/CE guidelines for industrial power systems.

Conclusion: The GE IS210AEBIH3BED is a versatile interface module for renewable energy and industrial control, offering robust protection, high efficiency, and seamless grid integration. Its dual functionality and environmental resilience make it a strategic choice for mission-critical applications.