Description

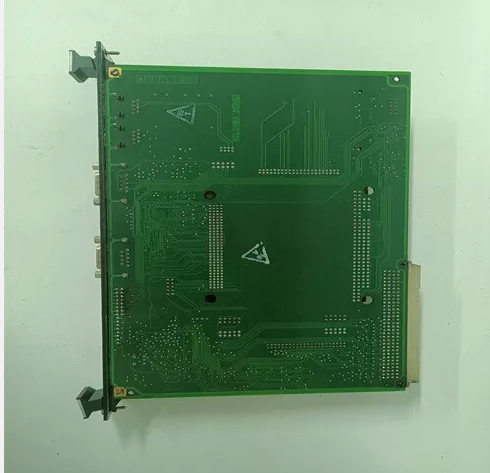

GE IS215ACLEH1A Application Control Layer Module

1. Product Description

The GE IS215ACLEH1A is a high-performance Application Control Layer (ACLE) module designed for GE’s EX2100 excitation control system, widely used in power generation and industrial automation. As a master controller, the IS215ACLEH1A integrates a 486/100 MHz or Pentium P5/266 MHz processor, supporting real-time communication via two 10BaseT Ethernet ports and two RS-232 serial interfaces (COM1/COM2). It occupies two slots in EX2100 racks (compatible with simplex/redundant thyristor/regulator control backplanes) and features non-volatile CompactFlash memory for firmware storage. Key functions include excitation parameter monitoring, alarm handling, and seamless integration with GE’s Toolbox software for configuration and diagnostics. The module is ideal for critical applications requiring robust control, such as gas/steam turbine excitation systems and industrial drive assemblies.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Application Control Layer (ACLE) |

| Series | GE EX2100 Excitation Control |

| Processor | 486 100 MHz or Pentium P5 266 MHz |

| Memory | 128 MB DRAM (expandable), CompactFlash |

| Interfaces | 2x 10BaseT Ethernet, 2x RS-232 (COM1/COM2) |

| Power Supply | 5V DC (via backplane) |

| Mounting | EX2100 VME rack (2 slots, 6U height) |

| Operating Temperature | 0°C to 45°C (32°F to 113°F) |

| Dimensions | 15.9 cm (H) x 10.2 cm (W) |

| Software | QNX OS, GE Toolbox support |

| LED Indicators | Active, OK, ENET, Status, Flash |

IS215ACLEH1A

3. Advantages and Characteristics

- High Processing Power: 266 MHz Pentium processor (optional) enables fast data processing for complex excitation algorithms.

- Redundancy Support: Compatible with EX2100 redundant control racks (e.g., IS200ERRB backplane) for fault-tolerant operations.

- Flexible Communication: Dual Ethernet ports and serial interfaces facilitate integration with turbines, HMIs, and third-party systems.

- Non-Volatile Storage: CompactFlash ensures firmware persistence without battery backup.

- Space-Efficient Design: 2-slot 6U form factor optimizes rack space while supporting advanced features (e.g., PCI/ISA bus interfaces).

4. Application Fields and Cases

- Industry Applications: Power generation (gas/steam/hydro turbines), industrial automation (drive systems), and energy management.

- Case Study: A U.S. power plant upgraded its steam turbine excitation system with the IS215ACLEH1A, reducing excitation response time by 15% and enabling remote diagnostics via Ethernet. The module’s CompactFlash memory simplified firmware updates, cutting downtime by 25%.

5. Competitive Comparison

Compared to similar control modules:

- Superior Integration: Native support for GE EX2100 systems (vs. generic controllers requiring custom adapters).

- Higher Density: 2-slot design with dual Ethernet/serial ports (vs. single-slot modules with limited interfaces).

- Long-Term Reliability: 3-year warranty (industry average: 1–2 years) and rugged construction for harsh environments (vibration/shock resistance).

IS215ACLEH1A

6. Selection Recommendations

- Compatibility: Ensure EX2100 rack/backplane compatibility (e.g., IS200ESBP, IS200EBKP) and firmware version ≥ 2.0.

- Performance Needs: Choose Pentium variant (266 MHz) for complex algorithms; 486 (100 MHz) suffices for basic control.

- Expansion Planning: Factor in optional accessories (e.g., 336A3582P1 serial cable) for remote monitoring.

7. Precautions

-

Installation: Follow ESD protocols; ensure proper grounding of the VME rack. Avoid physical disassembly (user-repairable components not accessible).

-

Firmware Management: Use GE Toolbox for firmware updates; verify checksum integrity before deployment.

-

Redundancy Setup: For online redundant systems, synchronize IS215ACLEH1A modules via backplane DPRAM (4K x 32-bit) to prevent data conflicts.

-

Environmental Limits: Operate within specified temperature/humidity ranges; avoid corrosive gases.