Description

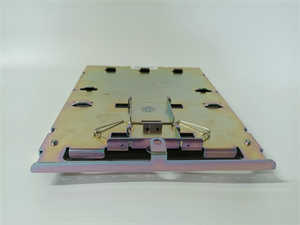

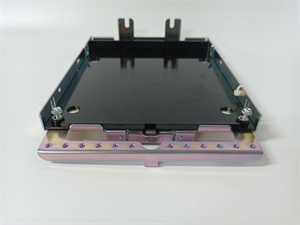

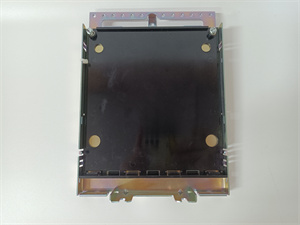

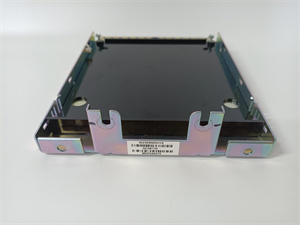

1. Product Description

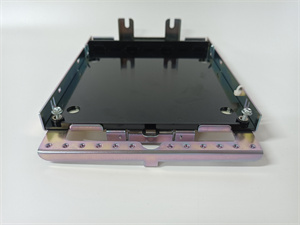

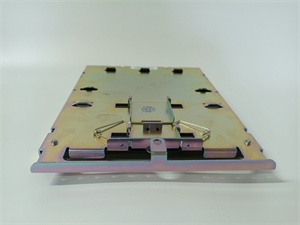

The GE IS230SNIDH1A is a significant component in GE’s industrial automation solutions, specifically tailored for use in the Mark VIe control system. This module serves as a digital input interface, playing a crucial role in collecting and transmitting discrete signals from various field devices to the control system. It is engineered to operate in the demanding environments typically found in industries such as power generation, oil and gas, and manufacturing.

The core function of the IS230SNIDH1A is to accurately detect and process digital signals, like the status of switches, sensors, and relays. These signals are then sent to the main control unit, enabling real – time monitoring and control of industrial processes. With its high – speed signal processing capabilities, it ensures that the control system can respond promptly to any changes in the field conditions.

One of the key advantages of the IS230SNIDH1A is its high level of reliability. It is built with industrial – grade components that can withstand harsh temperatures, vibrations, and electrical noise. This makes it suitable for long – term, continuous operation in critical industrial applications where system downtime can lead to significant losses.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 24V DC (±10%) |

| Input Voltage Range | 0 – 24V DC for digital inputs |

| Input Channels | 16 isolated digital input channels |

| Isolation Voltage | 2500Vrms |

| Response Time | < 5 ms |

| Communication Interface | Serial communication for data transfer to the control system |

| Operating Temperature | – 40°C to 70°C |

| Humidity | 5% – 95% non – condensing |

| Dimensions | 100mm x 150mm x 50mm (W x H x D) |

| Weight | 0.6 kg |

| Compatibility | Compatible with GE Mark VIe control system |

IS230SNIDH1A

3. Advantages and Features

- High – Speed Signal Processing: The IS230SNIDH1A can process digital input signals in less than 5 ms, allowing for real – time control and quick response to changing industrial conditions. For example, in a power generation plant, it can rapidly detect the status of circuit breakers and transmit this information to the control system, enabling timely actions to ensure grid stability.

- Reliable Isolation: With an isolation voltage of 2500Vrms, it effectively protects the control system from electrical interference and surges from the field devices. This has been proven in numerous industrial settings where electrical noise is common, such as in steel mills, where it maintains stable operation and accurate signal transmission.

- Wide Temperature Range: It can operate in temperatures ranging from – 40°C to 70°C. This makes it suitable for use in various geographical locations and industrial environments, whether it’s a cold – climate oil rig or a hot – climate power plant.

- Easy Integration: Designed to be easily integrated into the GE Mark VIe control system, it simplifies the installation and configuration process. This reduces the time and cost associated with system upgrades and expansions.

4. Application Areas and Application Cases

- Application Areas:

- Power Generation: Used in gas turbines, steam turbines, and hydroelectric power plants to monitor the status of various components, such as valves, switches, and sensors.

- Oil and Gas: In oil refineries, pipelines, and offshore platforms, it helps in monitoring the operation of pumps, compressors, and safety devices.

- Manufacturing: For monitoring the status of conveyor belts, robotic arms, and other automated equipment in factories.

- Application Case:

- In a large – scale gas power plant, the IS230SNIDH1A was installed to monitor the status of 200 digital input points related to turbine control and safety systems. Since its installation, the plant has experienced a 15% reduction in unplanned shutdowns due to its accurate and timely signal detection. This has not only increased the overall power generation efficiency but also reduced maintenance costs.

5. Competitor Comparison

Compared to similar digital input modules in the market, the IS230SNIDH1A has several advantages. Firstly, its high – speed signal processing is superior to many competitors, which is crucial for real – time control applications. Secondly, the wide operating temperature range allows it to be used in more extreme environments where some competing products may fail. Additionally, its seamless integration with the GE Mark VIe control system gives it an edge, as it eliminates the need for complex adapter solutions and reduces compatibility issues.

IS230SNIDH1A

6. Selection Recommendations

- Compatibility: Ensure that the module is compatible with your existing GE Mark VIe control system. Check the communication protocols and electrical interfaces to avoid any integration problems.

- Environmental Conditions: Evaluate the temperature, humidity, and electrical noise levels of your industrial environment. If your site experiences extreme temperatures or high electrical interference, the IS230SNIDH1A‘s features make it a suitable choice.

- Input Channel Requirements: Determine the number of digital input channels you need. The IS230SNIDH1A provides 16 channels, which may be sufficient for many applications. However, if you require more channels, you may need to consider other options or multiple modules.

- Budget: While the IS230SNIDH1A offers high – end features and reliability, it’s important to consider your budget. Compare the cost of the module with its performance and long – term benefits to make an informed decision.

7. Precautions

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure proper grounding and wiring to prevent electrical interference. Use anti – static precautions during installation to avoid damaging the sensitive electronic components.

- Configuration: Configure the module correctly using the appropriate software tools provided by GE. Incorrect configuration can lead to inaccurate signal detection and system malfunctions.

- Maintenance: Regularly inspect the module for any signs of damage or wear. Clean the module periodically to remove dust and debris. Follow the recommended maintenance schedule provided by GE to ensure its long – term reliability.

- Safety: Always follow safety procedures when working with the module. Disconnect the power supply before performing any maintenance or installation tasks to avoid electrical shock.