Description

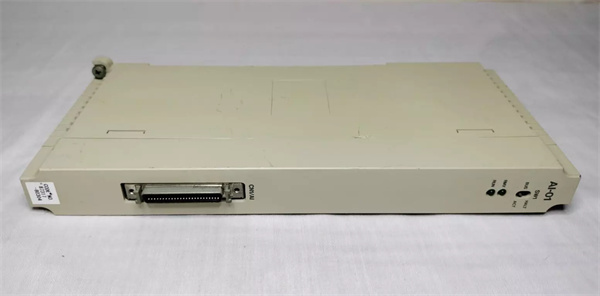

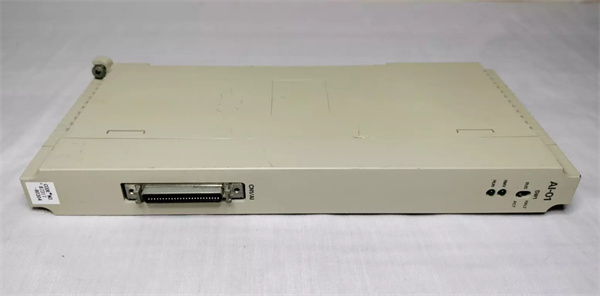

Product Description

The YASKAWA JACP-317803 is a high-performance programmable logic controller (PLC) designed for industrial automation and process control. Engineered for reliability and efficiency, the JACP-317803 integrates advanced features to optimize operations in diverse industrial environments. Its robust architecture supports seamless connectivity with sensors, actuators, and other automation components, making it ideal for applications requiring precise control and real-time monitoring. The YASKAWA JACP-317803 stands out for its high-speed processing, flexible I/O capabilities, and durable construction, ensuring consistent performance in harsh conditions.

Product Parameters

| Parameter | Specification |

|---|---|

| Type | Programmable Logic Controller (PLC) |

| Voltage | 24V DC (Input) / 24V DC (Output) |

| Communication Interfaces | Ethernet, RS-232, RS-485 |

| I/O Modules | Supports analog/digital input/output modules |

| Compatibility | YASKAWA PLC systems, third-party automation devices |

| Operating Temperature | -10°C to 55°C (Industrial Grade) |

| Mounting | DIN rail or panel mount |

YASKAWA JACP-317803

Advantages and Features

- High-Speed Processing: Delivers rapid response times (≤1ms cycle time) for complex control tasks, enhancing operational efficiency.

- Flexible Connectivity: Multiple communication interfaces (Ethernet, RS-232, RS-485) enable seamless integration with HMIs, SCADA systems, and IoT platforms.

- Durable Construction: Built with industrial-grade components (IP20 protection), resisting dust, vibrations, and temperature fluctuations.

- User-Friendly Programming: Intuitive software tools (e.g., YASKAWA’s PLC programming suite) simplify configuration and reduce commissioning time.

- Scalability: Expandable I/O modules support up to 256 I/O points, adapting to small-scale machinery or large industrial systems.

Application Areas and Case Studies

- Manufacturing: Assembly lines, packaging systems, and robotic automation.

- Process Industries: Chemical plants, food and beverage processing, and power generation.

- Building Automation: HVAC control, lighting systems, and security networks.

Case Study: A pharmaceutical manufacturing plant in Europe integrated the YASKAWA JACP-317803 to automate its filling line. The PLC’s high-speed processing and precise I/O control reduced downtime by 20% and improved product consistency, meeting FDA compliance standards.

Competitive Comparison

Compared to similar PLCs, the JACP-317803 offers superior thermal management (extended temperature range) and a built-in Ethernet interface, eliminating the need for additional communication modules. Its modular design also reduces installation costs by 15% compared to non-expandable alternatives.

YASKAWA JACP-317803

Selection Recommendations

- Compatibility: Ensure compatibility with existing YASKAWA systems (e.g., MP2000 series) or third-party devices.

- Environment: Choose IP20-rated models for indoor use or upgrade to ruggedized versions for outdoor/harsh environments.

- Budget: Balance I/O capacity and features (e.g., built-in Ethernet vs. add-on modules) based on project requirements.

Precautions

- Installation: Follow DIN rail mounting guidelines and ensure proper grounding to prevent EMI interference.

- Maintenance: Regularly inspect connectors and vents; replace batteries (for backup memory) every 5 years.

- Safety: Adhere to IEC 61131-5 safety standards for industrial control systems.

Conclusion

The YASKAWA JACP-317803 combines rugged reliability, advanced connectivity, and user-centric design to meet the demands of modern industrial automation. Whether optimizing manufacturing lines or enhancing process control, this PLC delivers performance and scalability.

The YASKAWA JACP-317803 combines rugged reliability, advanced connectivity, and user-centric design to meet the demands of modern industrial automation. Whether optimizing manufacturing lines or enhancing process control, this PLC delivers performance and scalability.