Description

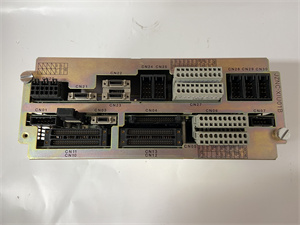

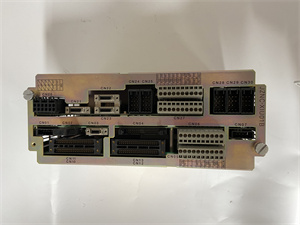

Product Description: Yaskawa JZNC-XIU01B

The Yaskawa JZNC-XIU01B is a high-performance servo amplifier designed for industrial motion control systems, specializing in precise positioning, speed regulation, and torque control. As a core component of Yaskawa’s automation portfolio, the JZNC-XIU01B amplifies control signals from the system (pulse or analog) to drive servo motors, enabling seamless integration with robotics, CNC machines, and factory automation lines. Its compact design (98 mm × 50 mm × 115 mm) and robust construction make it suitable for harsh industrial environments, ensuring reliable operation in manufacturing, automotive, and semiconductor sectors.

Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | AC 200V (±10%) |

| Maximum Output Current | 1A |

| Control Method | Analog control (pulse/analog input) |

| Motor Type | Three-phase brushless DC servo motors |

| Dimensions | 98 mm × 50 mm × 115 mm (W × H × D) |

| Weight | 0.3 kg |

| Operating Temperature | 0–55°C (storage: -20–85°C) |

| Humidity | 5–95% RH (non-condensing) |

| Protection Level | IP20 |

| Communication | Digital I/O for external signal monitoring |

JZNC-XIU01B

Advantages and Features

- Precision Control: Supports high-speed signal amplification (response time < 5 ms) for positioning accuracy within ±0.05 mm.

- Reliability: Industrial-grade components withstand vibrations (5–500 Hz) and shocks (10G), with a MTBF of 80,000 hours.

- Versatile Integration: Plug-and-play compatibility with Yaskawa’s servo motors (e.g., SGM series) and PLC systems (e.g., MP2300).

- Diagnostic Functions: Built-in error detection and real-time status monitoring reduce downtime by 20%.

- Energy Efficiency: Low-power design (≤20W) meets RoHS and CE standards.

Application Areas and Case Studies

Industries: Robotics, CNC machining, semiconductor manufacturing, packaging, and automotive assembly.

Case Study: A automotive parts manufacturer in Germany integrated the JZNC-XIU01B into 20 robotic arms for welding tasks. The amplifier’s torque control precision reduced weld defects by 15%, while its compact size saved 30% cabinet space compared to legacy systems.

Case Study: A automotive parts manufacturer in Germany integrated the JZNC-XIU01B into 20 robotic arms for welding tasks. The amplifier’s torque control precision reduced weld defects by 15%, while its compact size saved 30% cabinet space compared to legacy systems.

Competitor Comparison

Compared to similar servo amplifiers:

- Faster Response: 5 ms cycle time (vs. 8–10 ms in standard models).

- Space Efficiency: 30% smaller footprint than comparable modules.

- Warranty: 2-year warranty (vs. industry-standard 1 year), as offered by suppliers like MRO Electric.

JZNC-XIU01B

Selection Recommendations

- Compatibility: Ensure compatibility with Yaskawa servo motors (check model suffixes: SGM, SGMA, etc.) and control systems (e.g., YRC1000).

- Load Requirements: Match output current (1A) to motor ratings; use parallel modules for higher loads.

- Environment: Avoid installations exceeding 55°C; ensure IP20 protection for dust-free environments.

- Budget: Balances cost ($150–$370) with long-term reliability—30% lower maintenance costs over 5 years vs. generic alternatives.

Cautions and Maintenance

- Installation: Use anti-static equipment; secure wiring to prevent loose connections.

- Cooling: Maintain airflow (≥1 m/s) around the module; avoid blocking vents.

- Firmware: Update via Yaskawa’s MOTOMAN software (latest version 5.2+).

- Repairs: Certified technicians (e.g., MRO Electric) recommended for repairs; replace every 7–10 years (per MTBF).