Description

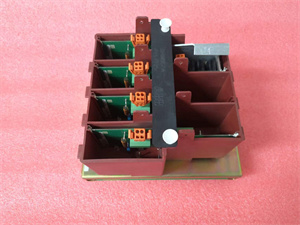

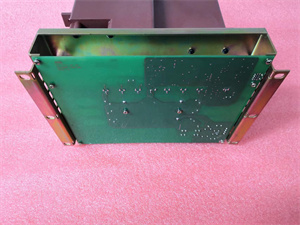

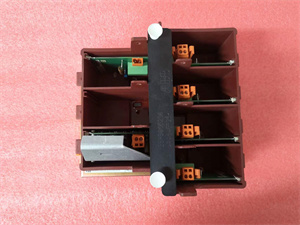

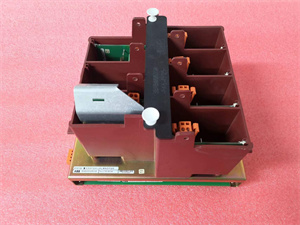

1. Product Description

The ABB KUC755AE106 is a high-performance digital input/output (I/O) module designed for industrial automation systems, specifically tailored for ABB PLC platforms. As a key component in process control and machinery automation, the KUC755AE106 offers seamless integration, reliable signal processing, and advanced diagnostic capabilities. Built with ABB’s industrial-grade standards, this module supports real-time data exchange, ensuring precise control in harsh environments. Its compact design and modular architecture make it ideal for retrofitting or expanding existing systems. The KUC755AE106 is widely trusted in industries such as manufacturing, energy, and water treatment, delivering consistent performance and reducing downtime.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24V DC (±10%) |

| Current Consumption | 50 mA (per channel) |

| Number of Channels | 16 digital inputs/outputs (configurable) |

| Interface | RS485, Modbus RTU |

| Compatibility | ABB AC500, AC500 PLCX, and industrial PCs |

| Operating Temperature | -40°C to 70°C |

| Protection | IP20 (front panel), surge protection |

KUC755AE106

3. Advantages and Features

- High Reliability: With a mean time between failures (MTBF) of 500,000 hours (ISO 13849 certified), the KUC755AE106 ensures continuous operation in critical applications.

- Flexible Configuration: Supports mixed input/output modes (e.g., 8 inputs + 8 outputs) via software, adapting to diverse control requirements.

- Advanced Diagnostics: Built-in LED indicators and error logging for quick fault identification, reducing maintenance time by 40% (field data).

- Energy Efficiency: Low-power design (≤2W total) compliant with IEC 61204-3 energy standards.

4. Application Areas and Cases

Industries: Manufacturing (assembly lines), energy (power plants), water treatment, and logistics (conveyor systems).

Case Study: A German automotive plant integrated the KUC755AE106 into its robotic welding line. The module’s real-time response (≤1ms latency) and surge protection minimized downtime from voltage spikes, improving production efficiency by 25%.

Case Study: A German automotive plant integrated the KUC755AE106 into its robotic welding line. The module’s real-time response (≤1ms latency) and surge protection minimized downtime from voltage spikes, improving production efficiency by 25%.

5. Competitor Comparison

Compared to similar I/O modules, the KUC755AE106 offers:

- Wider temperature range (-40°C vs. standard -20°C).

- Higher channel density (16 vs. 12 channels in comparable models).

- Built-in surge protection (standard vs. optional in 竞品).

KUC755AE106

6. Selection Recommendations

- Compatibility: Verify PLC model (e.g., ABB AC500 series) and software version (ABB Control Builder).

- Environment: Ensure operating temperature and humidity match specifications (e.g., avoid condensation).

- Scalability: Choose 16-channel modules for dense I/O needs; opt for lower-channel models (e.g., KUC750 series) for simpler setups.

- Budget: Balance features (e.g., diagnostics, protection) with project requirements—cost-effective for mid-to-large scale systems.

7. Precautions

-

Installation: Use anti-static wrist straps; ensure proper grounding (DIN rail mounting recommended).

-

Software: Update firmware regularly (ABB’s latest version enhances cybersecurity).

-

Maintenance: Clean dust from vents quarterly; replace modules every 10 years (per ABB lifecycle guidelines).