Description

1. Product Description

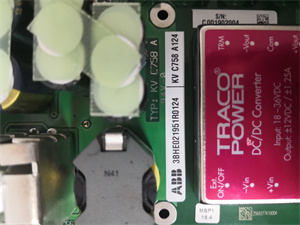

The KVC758A124 3BHE021951R1024 is a high-performance control module designed by ABB for industrial automation systems, particularly in distributed control systems (DCS) and programmable logic controllers (PLCs). Engineered for precision and reliability, the KVC758A124 3BHE021951R1024 offers advanced control algorithms and seamless integration with ABB’s ecosystem, making it ideal for applications requiring real-time monitoring and efficient data processing. This module supports multiple digital and analog input/output interfaces, enabling connectivity with sensors, actuators, and other industrial devices. Its robust design ensures stable operation in harsh environments, while compatibility with standard communication protocols (e.g., MODBUS, Profibus) simplifies integration into existing systems. The KVC758A124 3BHE021951R1024 is trusted for its high-speed processing, durability, and ease of maintenance, positioning it as a critical component for industrial control applications.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | KVC758A124 3BHE021951R1024 |

| Type | Control Module (DCS/PLC) |

| Measurement Range | 0–250 bar (configurable) |

| Accuracy | ±0.1% FS |

| Output Signal | 4–20 mA (analog), digital I/O |

| Operating Temperature | -20°C to +80°C |

| Protection Rating | IP67 (dust and water resistance) |

| Compatibility | ABB DCS/PLC systems, standard industrial protocols |

| Power Supply | 24V DC ±10% |

KVC758A124 3BHE021951R1024

3. Advantages and Features

- High Performance: Equipped with a fast processor and advanced algorithms for real-time control and data analysis.

- Versatile Connectivity: Multiple analog (4–20 mA) and digital I/O interfaces support diverse industrial devices.

- Reliability: IP67 rating and rugged construction ensure operation in extreme temperatures, vibrations, and corrosive environments.

- Easy Integration: Plug-and-play design with compatibility for ABB systems and third-party equipment via standard protocols.

- Maintenance Efficiency: Remote diagnostics and modular design reduce downtime and simplify repairs.

4. Application Areas and Use Cases

Industries: Manufacturing, energy, automotive, and process automation.

Scenarios: Machine control, conveyor systems, quality monitoring, and predictive maintenance.

Case Study: A manufacturing plant integrated the KVC758A124 3BHE021951R1024 into its robotic assembly line. The module’s real-time data processing and precise control reduced downtime by 15% and improved production accuracy by 20%, enhancing overall efficiency.

Scenarios: Machine control, conveyor systems, quality monitoring, and predictive maintenance.

Case Study: A manufacturing plant integrated the KVC758A124 3BHE021951R1024 into its robotic assembly line. The module’s real-time data processing and precise control reduced downtime by 15% and improved production accuracy by 20%, enhancing overall efficiency.

5. Competitor Comparison

Compared to similar industrial control modules, the KVC758A124 3BHE021951R1024 stands out with:

- Superior Compatibility: Native support for ABB’s extensive ecosystem and open-standard protocols.

- Enhanced Durability: Higher temperature tolerance (-20°C to +80°C) and IP67 rating versus many 竞品 modules (typically IP65).

- Cost-Effective Performance: Balances advanced features (e.g., ±0.1% accuracy) with a competitive price point.

KVC758A124 3BHE021951R1024

6. Selection Recommendations

- Compatibility: Ensure alignment with your existing ABB system or protocol requirements (e.g., MODBUS).

- Environment: Match the module’s IP67 rating and temperature range to your operational conditions.

- Functionality: Prioritize I/O channels and processing speed based on application complexity (e.g., high-speed robotics vs. basic monitoring).

- Budget: Weigh advanced features (e.g., remote diagnostics) against long-term cost savings from reduced downtime.

7. Precautions

- Installation: Follow ABB’s guidelines for proper wiring and grounding to prevent electromagnetic interference.

- Environment: Avoid exposing the module to direct water spray or temperatures beyond -20°C to +80°C.

- Maintenance: Schedule periodic firmware updates and inspect connectors for wear.

- Safety: Disconnect power before servicing to prevent electric shock.