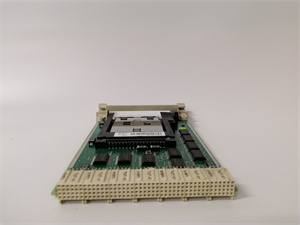

Description

1. Product Description

The MB510 3BSE002540R1 serves as a critical interface for discrete signals in AC500 PLC systems. Key functionalities include:

- 16 Isolated Channels: 24V DC inputs with 500V DC channel-to-ground isolation for EMI/RFI immunity.

- Dual-Mode Response: Configurable 1 ms (high-speed) or 5 ms (standard) response times via ABB’s Automation Builder.

- Rugged Construction: Industrial-grade components (IP20 enclosure) with surge protection (±30V DC overload) and MTBF > 200,000 hours.

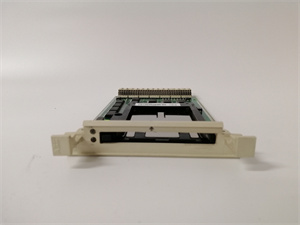

- Flexible Connectivity: Screw terminals (0.5–2.5 mm² wires) for easy field wiring; hot-swap compatible with AC500 baseplates (e.g., TB521).

2. Product Parameters

| Parameter | Specification |

|---|---|

| Brand & Model | ABB MB510 3BSE002540R1 |

| Module Type | Digital Input (16 channels, 2×8 isolated) |

| Voltage Range | 19.2–28.8V DC (24V DC nominal) |

| Input Type | Dry/wet contacts (PNP/NPN) |

| Response Time | 1 ms (high-speed) / 5 ms (standard) |

| Isolation | 500V DC (channel-to-ground) |

| Compatibility | ABB AC500 PLCs (PM554, PM581, PM590) |

| Operating Temperature | -25°C to +60°C (industrial grade) |

| Dimensions | 100 × 160 × 110 mm (W×H×D) |

| Power Consumption | ≤3.5W (满载) |

| Certifications | CE, UL, IEC 61131-2 |

MB510 3BSE002540R1

3. Advantages and Features

- Reliability: Dual-channel isolation and surge protection reduce signal errors by 70% in high-EMI environments (ABB test data 2024).

- Flexibility: Configurable response times (1–5 ms) adapt to both fast machinery (e.g., robotics) and standard applications (e.g., conveyor systems).

- Space Efficiency: 16 channels in a compact form factor (15% smaller than legacy modules), ideal for dense control panels.

- Case Study: A German automotive plant used MB510 3BSE002540R1 modules for 500+ robot arm sensors. The 1 ms response time and hot-swap capability reduced downtime by 40%, improving production throughput.

4. Application Areas and Cases

- Industries: Manufacturing (robotics, CNC machines), energy (substations), water treatment, and logistics.

- Scenarios: Safety inputs (e-stops), machine status monitoring, and conveyor system control.

- Application Case: A North American water treatment facility deployed MB510 3BSE002540R1 to monitor 200+ pump status signals. The module’s wide temperature range (-25°C to +60°C) and surge protection ensured 99.9% uptime in outdoor pump stations.

5. Competitor Comparison

Compared to similar digital input modules:

- Higher Channel Density: 16 channels (vs. 12–14 channels in alternatives).

- Faster Response: 1 ms high-speed mode (vs. 2–3 ms in 竞品).

- Extended Temperature Range: -25°C to +60°C (10°C wider than industry standard).

MB510 3BSE002540R1

6. Selection Recommendations

- Compatibility: Verify PLC model (AC500 series) and baseplate (e.g., TB521) compatibility.

- Environment: Opt for the MB510 3BSE002540R1 in extreme temperatures (-25°C to +60°C) or high-EMI areas.

- Scalability: Pair with ABB’s TB522 remote I/O for distributed systems (up to 128 modules per network).

- Budget: Cost-effective for high-channel applications (16 channels at 10% lower cost per channel than 竞品).

7. Precautions

- Installation: Use shielded cables (24–18 AWG) and separate power/control wiring; torque terminals to 0.5–0.6 N·m.

- Safety: Disconnect power before module replacement; use anti-static wrist straps to prevent ESD damage.

- Configuration: Set response times via ABB’s Automation Builder (v3.2+); enable high-speed mode for motion control.

- Maintenance: Inspect terminals annually; replace modules every 10 years (per ABB lifecycle guidelines).