Description

1. Product Description

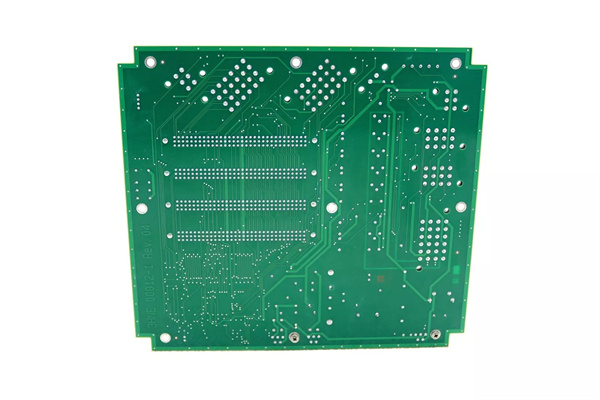

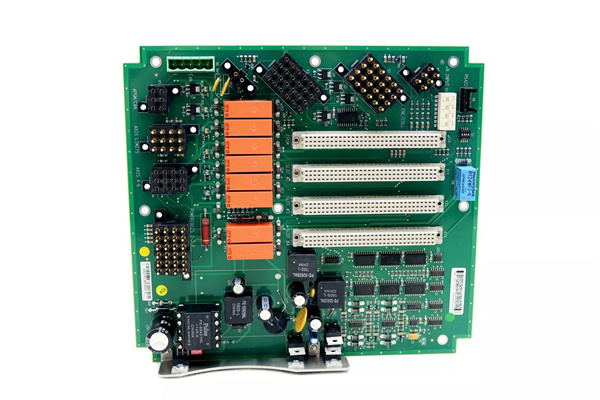

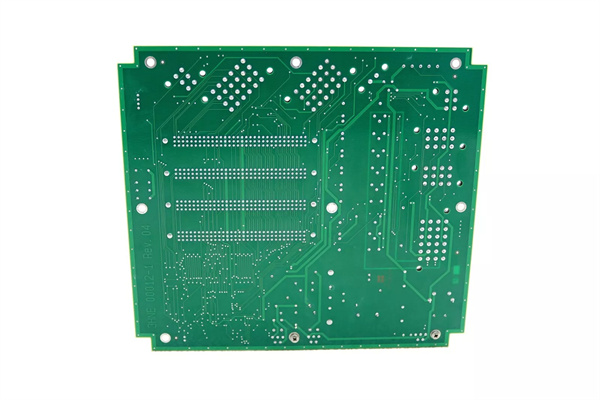

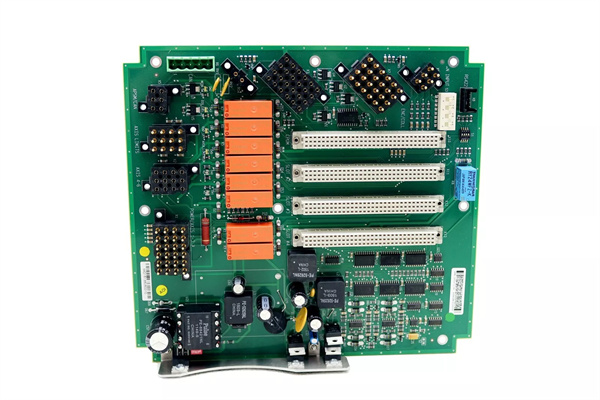

The ABB MCOB-01 3HNE00010-1 is a high-performance network communication module designed for industrial automation systems, particularly compatible with ABB’s S900 I/O platform. As a key component in distributed control systems (DCS), the MCOB-01 3HNE00010-1 enables seamless data exchange between master stations and remote I/O devices, supporting protocols like PROFIBUS-DP for reliable real-time communication. Its compact design and rugged construction make it suitable for harsh environments, including hazardous zones (Zone 1/2), ensuring operational stability in industries such as manufacturing, energy, and chemical processing. The module integrates an internal power management system, allowing hot-swap capabilities for maintenance without system downtime. With advanced diagnostics and configurable parameters, the MCOB-01 3HNE00010-1 optimizes system efficiency and reduces operational costs.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | MCOB-01 3HNE00010-1 |

| Type | Network Communication Module |

| Voltage | 24V DC (±10%) |

| Interface | PROFIBUS-DP (9.6 kbps to 12 Mbps) |

| I/O Compatibility | S900 I/O modules (up to 7 expansion modules) |

| Mounting | DIN rail (现场安装) |

| Weight | 2.5 kg |

| Operating Temperature | -40°C to +70°C (wide range) |

| Certifications | ATEX/IECEx (Zone 1/2), IP65 防护等级 |

| Data Rate | Up to 12 Mbps |

| Diagnostics | LED indicators for power, communication, error |

MCOB-01 3HNE00010-1

3. Advantages and Features

- Hot-Swap Capability: Internal power management allows online replacement of modules (e.g., power supply units) without system shutdown, minimizing downtime.

- Hazardous Environment Compliance: Certified for Zone 1/2 hazardous areas, ensuring safety in explosive atmospheres (e.g., chemical plants, oil refineries).

- Wide Temperature Range: Operates from -40°C to +70°C, suitable for extreme industrial environments.

- Modular Design: Supports up to 7 I/O expansion modules (4 analog + 3 digital), enabling flexible system scaling.

- Reliable Communication: PROFIBUS-DP protocol ensures low latency and high data integrity, with redundancy options for critical applications.

- Compact Footprint: Space-saving design (35mm width) ideal for distributed control setups.

4. Application Areas and Case Studies

Industries: Manufacturing, energy, oil & gas, chemical processing, water treatment.

Use Cases:

Use Cases:

- Manufacturing: Integrates with robotic assembly lines to monitor real-time production data (e.g., automotive factories).

- Energy: Controls distributed generators in smart grids, ensuring seamless synchronization.

- Case Study: A European automotive plant reduced downtime by 30% using the MCOB-01 3HNE00010-1 in their automated welding cells. The module’s hot-swap feature and hazardous zone certification allowed maintenance during production, improving overall equipment effectiveness (OEE).

5. Competitor Comparison

Compared to similar modules, the MCOB-01 3HNE00010-1 offers:

- Superior Temperature Range: Supports -40°C to +70°C (versus standard 0°C to +50°C in 竞品).

- Higher Expansion Capacity: Up to 7 I/O modules (versus 4–5 in comparable products).

- Integrated Hot-Swap: No external power cycling required for module replacement (a common limitation in legacy systems).

- Hazardous Zone Certification: ATEX/IECEx compliance as standard, reducing certification costs for end-users.

MCOB-01 3HNE00010-1

6. Selection Recommendations

- Compatibility: Ensure compatibility with your DCS platform (e.g., ABB S900 I/O).

- Environment: Specify modules with appropriate certifications (e.g., ATEX) for hazardous zones.

- Scalability: Choose based on I/O requirements (e.g., 4 analog + 3 digital modules for complex processes).

- Budget: Balance features (e.g., hot-swap, redundancy) with project costs—ideal for mid-to-high complexity systems.

7. Precautions

- Installation: Follow ABB’s guidelines for DIN rail mounting and wiring (IP65 protection required for outdoor use).

- Electrostatic Discharge (ESD): Use antistatic equipment during handling to prevent damage.

- Firmware Updates: Regularly update firmware via ABB’s engineering tools for optimal performance.

- Maintenance: Inspect connectors and cables quarterly; replace modules showing signs of wear (e.g., corrosion).

- Safety: Disconnect power before servicing non-hot-swappable components.