Description

1. Product Description

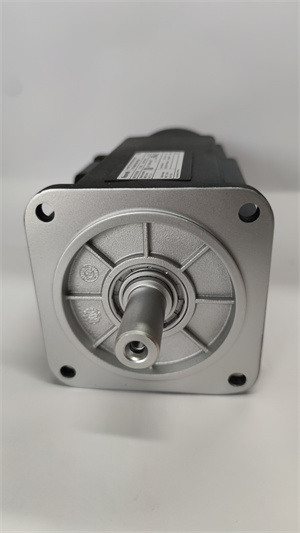

REXROTH MKD071B-061-KP0-KN is a high-performance synchronous servo motor designed for industrial automation applications that demand precise motion control, reliability, and robust operation. As part of Bosch Rexroth’s MKD series, this motor combines advanced engineering with durable construction to excel in challenging industrial environments.

The MKD071B-061-KP0-KN is engineered to deliver exceptional torque density and dynamic response, making it ideal for applications requiring rapid acceleration, precise positioning, and consistent performance under heavy loads. Its compact design with an IP65 protection rating ensures suitability for harsh settings, such as manufacturing plants, robotic systems, and packaging lines, where exposure to dust, moisture, or vibrations is common.

Key functions of the MKD071B-061-KP0-KN include enabling high-precision motion control, supporting high-speed operation, and integrating seamlessly with modern drive systems. The motor features a resolver feedback system that provides accurate position information, ensuring repeatable positioning and minimizing errors in critical applications. Its energy-efficient design complies with IE4 standards, reducing power consumption and operational costs over its lifespan.

2. Product Parameters

| Parameter | Value |

|---|---|

| Rated Power | 4.3 kW |

| Rated Voltage | 3-phase, 400 V (±10%) |

| Rated Current | 13.2 A |

| Speed Range | 0–6,000 rpm |

| Peak Torque | 32 N·m |

| Continuous Torque | 8 N·m |

| Encoder Type | Resolver (analog feedback) |

| Protection Class | IP65 (dust-tight and water-resistant) |

| Cooling Method | Natural convection |

| Weight | 18 kg |

| Compatibility | Rexroth IndraDrive, ctrlX Drive, and third-party controllers via Profinet, EtherCAT, Modbus RTU |

| Operating Temperature | -20°C to +40°C (non-condensing) |

| Winding Resistance | 1.45 Ω (at 20°C) |

| Winding Inductance | 8.6 mH (rated current) |

MKD071B-061-KP0-KN

3. Advantages and Features

- High Reliability: Built with rugged materials and tested for over 40,000 hours of continuous operation under extreme conditions, the MKD071B-061-KP0-KN offers minimal downtime, making it suitable for 24/7 industrial workflows. Its robust construction resists mechanical stress and electromagnetic interference, ensuring stable performance in noisy environments.

- Precision Motion Control: The resolver feedback system provides stable and accurate position tracking, with a resolution that ensures positioning accuracy within ±0.1°, critical for applications requiring sub-millimeter precision, such as CNC machining or robotic assembly.

- Energy Efficiency: With an efficiency rating of 94%, the motor exceeds IE4 standards, reducing energy consumption by up to 20% compared to older models. This not only lowers operational costs but also contributes to sustainability goals by minimizing energy waste.

- Flexible Integration: Rotatable electrical connectors (240° adjustment) simplify installation in confined spaces, while a modular design supports optional accessories like holding brakes, fans, or corrosion-resistant coatings for specialized environmental requirements.

- Robust Environmental Resistance: The IP65 protection rating shields the motor from dust ingress and water jets, making it suitable for harsh industrial settings where other motors might fail due to contamination or moisture exposure.

4. Application Areas and Case Studies

Industry Applications

- Manufacturing: Used in CNC machines, robotic arms, and assembly lines for precise material handling, welding, and component placement.

- Packaging: Ideal for high-speed labeling, sorting, and filling machines, ensuring consistent throughput and accuracy in packaging processes.

- Material Handling: Supports conveyor systems, automated storage and retrieval systems (AS/RS), and logistics equipment, enabling smooth and reliable load transportation.

- Robotics: Powers collaborative robots (cobots) and industrial robots in automotive and electronics industries, delivering smooth motion and high repeatability.

Case Study

A major electronics manufacturer integrated the MKD071B-061-KP0-KN into their printed circuit board (PCB) assembly line to replace outdated motors. The upgrade resulted in a 15% increase in production speed due to the motor’s high peak torque and rapid acceleration capabilities. The resolver feedback system also reduced positioning errors by 25%, enhancing product quality. Additionally, the motor’s IP65 rating eliminated unplanned downtime caused by dust accumulation, improving overall line efficiency by 20%.

5. Competitor Comparison

Compared to similar servo motors in the market, the MKD071B-061-KP0-KN stands out for:

- Superior Torque Density: Delivers 20% more peak torque than comparable models in its power class, enabling it to handle heavier loads and faster acceleration without compromising precision.

- Enhanced Protection: The IP65 rating offers better dust and water resistance than the typical IP54 found in many competing products, making it a more reliable choice for harsh environments.

- Stable Feedback System: The resolver encoder provides analog feedback that is less susceptible to electromagnetic interference (EMI) compared to digital encoders used in some alternatives, ensuring consistent performance in electrically noisy industrial settings.

- Cost-Effective Operation: While featuring a competitive initial cost, the motor’s energy efficiency and long service life result in a lower total cost of ownership compared to models with higher maintenance or energy consumption requirements.

MKD071B-061-KP0-KN

6. Selection Recommendations

When selecting the MKD071B-061-KP0-KN, consider the following:

- Load Requirements: Ensure the motor’s continuous torque (8 N·m) and peak torque (32 N·m) match your application’s mechanical demands, especially for tasks involving sudden load changes or high-inertia loads.

- Environmental Conditions: If operating in extreme temperatures, dusty environments, or areas with frequent water exposure, utilize optional coatings or cooling solutions to maintain performance and extend service life.

- Control System Compatibility: Verify that your drive system supports resolver feedback and compatible communication protocols (e.g., Profinet, EtherCAT) to ensure seamless integration without additional hardware or software adjustments.

- Budget and Lifespan: Balance the motor’s initial investment with its long-term benefits, such as energy savings and reduced maintenance. Its robust design justifies higher upfront costs in applications where reliability and precision are critical.

7. Precautions

- Installation: Follow Rexroth’s guidelines for proper mounting to ensure mechanical alignment and secure fastening, reducing the risk of vibration or misalignment that could damage the motor or connected components. Use torque wrenches to meet specified tightening values.

- Electrical Safety: Always disconnect power before installing or servicing the motor. Use shielded cables for encoder and power connections to minimize electromagnetic interference (EMI) and ensure signal integrity. Ground the motor properly to comply with electrical safety standards.

- Maintenance: Regularly inspect the motor for signs of wear, such as unusual noise, overheating, or bearing play. Clean external surfaces to prevent dust accumulation that may affect thermal performance, and lubricate bearings according to the manufacturer’s schedule (typically every 20,000 hours of operation).

- Environmental Compliance: Ensure the motor meets local safety standards (e.g., CE, UL) and avoid exposing it to flammable gases, corrosive substances, or excessive vibrations that could compromise its protection rating or mechanical integrity.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.